Better floor performance starts with a solid subfloor system

Meeting acoustic performance requirements

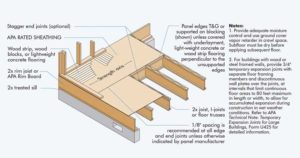

Lightweight concrete and gypcrete toppings are frequently installed over engineered wood floor framing systems in multifamily and commercial construction. Such composite floor systems are typically constructed as fire-rated assemblies with code-compliant fire and acoustic performance.

In recent years, the WSP industry has developed all-wood floor systems using single- or double-layer floor sheathing meeting both fire and acoustic performance requirements without the use of concrete or gypcrete topping.

These all-wood floor systems employ thick subfloor sheathing, such as a single layer of 1 1/8 performance category panel or double layers of 19/32 performance category top layer over 23/32 performance category base layer. Conventional light-frame floor construction is typically constructed with a single layer of 23/32 performance category floor sheathing. All-wood floor systems have the advantage of speedy construction because they eliminate construction delays caused by the installation of lightweight concrete or gypcrete topping. Additionally, these floors are stiffer than conventional light-frame floors.

In supporting the development of all-wood floor systems without lightweight gypcrete or concrete topping, APA conducted a series of acoustic tests for code compliance based on sound transmission class (STC) and impact insulation class (IIC) ratings. Detailed descriptions for STC and IIC ratings are provided in APA Design/Construction Guide: Noise-Rated Systems (Form W460). The double-layer floor assembly (19/32 performance category top later over 23/32 performance category base layer) provides similar acoustic performance to the single-layer (1 1/8 performance category) floor assembly.

Floorcovering material options

A variety of floorcovering materials are available (see Table 1 in APA form T230 for STC and IIC ratings). For vinyl and quarry tiles and hardwood flooring, a sound mat should be installed between the floorcovering and sheathing.

Cushioned vinyl

Vinyl sheet flooring with 3.5 mm (138 mils) in minimum thickness and 2.6 kg/m2 (0.53 psf) in minimum weight.

Vinyl tile

Minimum thickness of 5 mm (197 mils) and 11 kg/m2 (2.21 psf) minimum over 5-mm sound mat.

Quarry tile

Minimum thickness of 12.5 mm (1/2 in.) and 27 kg/m2 (5.6 psf) minimum weight attached to a 5-mm sound mat using thin-set mortar.

Hardwood flooring

Minimum thickness of 9.7 mm (382 mils) and 5.5 kg/m2 (1.12 psf) in minimum weight over 5-mm sound mat.

Carpet and pad

Minimum thickness of 1.2 kg (44-ounce) carpet with 11 mm (433 mils) and 2.7 kg/m2 (0.56 psf) in minimum weight over a foam rubber pad of 9.5 mm (374 mils) in thickness and 2.3 kg/m2 (0.48 psf) in weight.

Sheathing options

WSP floor sheathing meeting the code requirements should be installed perpendicular to the I-joist framing. It is not required to glue the floor sheathing to the I-joist framing. However, the designer may require the floor sheathing to be glued to the I-joist framing for increased structural performance.