Better blankets for greener buildings

Thermal insulation

In very basic terms, Mother Earth always wants to sustain balance. Therefore, heat transfers from higher temperature to lower temperature. There are three modes of heat transfer:

- conduction (within solids and also, negligibly, in fluids);

- convection (in fluids); and

- radiation (without any solid or fluid medium).

To reduce conduction, layers of material with high thermal resistivity—such as wood framing—should be used to construct the structural part of skin assembly as much as possible. Reducing radiation can be achieved by using material with low emissivity (i.e. poor absorber and good reflector of long-wave radiation), such as applying a very thin layer of metal film on low-emissivity (low-e) glass and laminating aluminum foil to sheathing board.

Air has the highest thermal resistivity among naturally existing materials, but circulation of air in big voids reduces its resistivity due to convection. Therefore, forming smaller compartments within the cavity would produce a good insulator. Depending on the arrangement of those compartments and used materials, the insulation types would rank in performance.

Many types of insulating materials are available and used in buildings. The most commonly used include:

- fibrous insulation, such as rock wool;

- rigid insulation, such as expanded polystyrene (EPS) as well as extruded polystyrene (XPS); and

- sprayed polyurethane foam (SPF), which consists of polyurethane and resin.

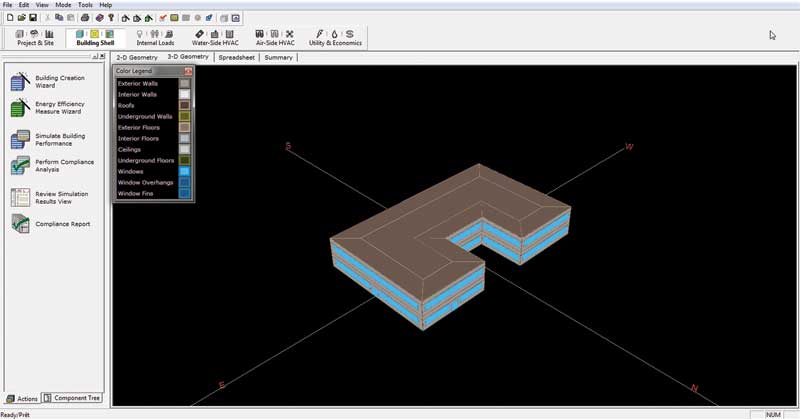

Understanding the final thermal behaviour of an exterior wall, during the design stage, is crucial to achieve an acceptable building enclosure.

Aside from increasing thermal insulation and improving airtightness, reducing thermal bridging has to be carefully addressed. Solving thermal bridging in buildings is no easy task. To transfer structural loads between the components of exterior assemblies, many engineers and architects use metal brackets—Z-girts, masonry veneer brackets angles, and ties. It does not take a crystal ball to predict seeing more thermally broken connectors and innovative technologies to deal with this issue. Moreover, structural steel members protruding through the thermal layer pose an even harder challenge, since the transferable dead and live loads are usually higher in value—cantilevered framing at canopies or balconies provides a case in point. Upward trending thermography can be utilized to identify thermal bridging and verify repair strategies in new and existing buildings.

We have successfully made our modern buildings tighter and improved their thermal performance. However, we are now challenged to deal with some side effects, such as condensation, circulation, and indoor air quality (IAQ). Additionally, while contemporary construction is arguably smarter and more efficient, it can also be less durable. Products used in building envelopes that are less forgiving of water include traditional gypsum board and wood sheathing. In general, we expect the main structure of a building to serve for 75 years or more, while various components of the building skin are designed for considerably less than that, depending on the assembly’s overall construction and maintenance.

Images © Bigstock.com

Condensation risk

Caused by precipitation of water vapour from air onto colder surfaces, condensation is dampness on or inside building components (i.e. surface and interstitial condensation, respectively). Surface condensation is readily visible (e.g. misting of windows), and can be managed by providing sufficient ventilation and heat. (An alternate solution involves simply accepting the results and specifying the use of, for example, condensation gutters in some skylight assemblies.)

Surface condensation will eventually dry off. Consequently, for humidified spaces when it is cold outside, the suggestion is often to leave window curtains open to allow the heat from the interior to increase the inner surface temperature. This reduces the condensation risk, and lets the condensed water evaporate.

In humid, hot climates, surface condensation may form on the outside boundary of the wall system. This is not as critical to the building performance, provided moisture does not condense within the building’s assemblies. Although in high-rise towers, condensation on exterior glazing poses some challenges, as it is hard to be wiped off, and attracts dust.

Interstitial condensation—the aforementioned formation of moisture within the exterior cladding assemblies—is more problematic because it attacks the wall assembly from within. By the time it is detected, the assembly could be at a late stage of deterioration. In buildings, interstitial condensation could cause:

- premature failure of insulated glass panels;

- beads of water on surfaces;

- damage to interior finishes;

- dampness of absorbent materials;

- mould growth;

- corrosion and rot to building components; and

- structural concerns.