Assessing thermal performance and resiliency of contemporary buildings

by nithya_caleb | January 25, 2019 12:00 am

by John F. Straube, PhD, P.Eng., and Brian J. Hall

[1]

[1]Requirements for energy and thermal performance and resilience are growing more stringent, as well as playing an increasingly significant role in building codes throughout North America. However, understanding and meeting the requirements has also become more complex for building designers. At the same time, it has become clear important decisions regarding basic structure, enclosure assembly, and window area need to be made early in the design process to achieve the most cost-effective, energy-efficient, and comfortable building. Designers, developers, and owners must be compliant with modern building codes, and familiar with suitable methods for quickly estimating, at an early stage, the thermal performance and resiliency of building systems.

Energy code

The 2017 edition of the National Energy Code of Canada for Buildings (NECB) is an important step toward Canada’s goal of achieving net-zero energy ready (NZER) buildings by 2030 for new construction, as presented in the Pan-Canadian Framework. NECB 2017 supports this goal by:

- reducing the overall thermal transmittance of roofs, fenestration, and doors;

- minimizing losses through thermal bridging in building assemblies; and

- limiting the allowable percentage of skylight area.

The new edition also introduced more stringent requirements for energy recovery systems and incorporated interior and exterior lighting requirements.

The current environment

[2]

[2]Images courtesy The Canadian Pre-cast/Prestressed Concrete Institute

Current Canadian and U.S. building codes are heavily influenced by energy considerations. This was not always the case. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) published one of the first building energy standards (ASHRAE 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings) in 1975. The earliest national standard for building energy performance, NECB, was first introduced in 1971 while the International Energy Conservation Code (IECC) was not launched in the United States until 2000.

Early on, neither ASHRAE 90.1 nor the other two model energy codes were widely adopted. In Canada, some provincial and municipal governments used NECB as the basis for design and construction of new public buildings. Institutions such as universities or large public companies also made compliance with NECB or ASHRAE 90.1 a requirement for the design and construction of an increasing number of high-profile buildings. As public awareness and concern grew over global warming, greenhouse gas (GHG) emissions, and other environmental issues, so did the prevalence of energy and environmental rating systems such as Leadership in Energy and Environmental Design (LEED). In time, rating programs, energy regulations, and model energy codes encouraged the evolution of building standards. Today’s codes integrate many of the energy and thermal performance requirements from earlier regulations and model codes. Dependence on traditional materials and enclosure systems has also changed.

The industry has adopted and continues to develop new and improved ways of building to respond to these changing code requirements and increasing performance expectations. Many different types of building systems are now being used throughout North America, and this has prompted the development of more accurate methods for the comparison and assessment of their actual in-service thermal performance. The focus on better methods of predicting heat flow has, or soon will have, entered mainstream building codes across North America. These methods of accounting for heat flow will impact all building enclosure systems.

The purpose of the “Meeting and Exceeding Building Code Thermal Performance Requirements for Precast Concrete Walls” guide by RDH Building Science is to allow design and energy modelling to proceed by estimating what thickness of insulation or changes in construction details would be required for specific R-value targets. The information is also intended to assist designers and owners in making better comparisons between systems in a project’s early stages (when many irrevocable decisions are made). Due to the specifics of the overall building design, the results may not be sufficient to demonstrate code compliance—additional energy modelling or trade-off analysis may be required. The guide summarizes various compliance paths for meeting building energy codes. As these paths include trade-off options, various levels of insulation can be used in walls for different projects. To accommodate this reality and simplify the document, thermal performance is provided for a range of insulation options. The thermal performance of select details repeated throughout a building is also considered.

The approach taken is to:

- begin with an overview of the current thermal performance requirements in the Canadian codes;

- provide an explanation of approximate methods to predict the thermal performance of common precast concrete systems for use during early design stages along with examples; and

- present examples of precast enclosure system solutions, and the calculation of their R-value, to meet the thermal performance requirements.

Building codes

[3]

[3]Building codes across North America define the lowest performance designers are legally allowed to provide. Owners and various green building standards routinely set higher targets. The most common energy standards referenced by Canadian building codes are NECB (2011 or 2015 edition) and versions of ASHRAE 90.1.

The Ontario Building Code (OBC) provides several options in Supplementary Standard (SB) 10, “Energy Efficiency Requirements,” and Québec is governed by the Regulation Respecting Energy Conservation in the New Buildings Act.

Provinces update their building codes every few years. Therefore, designers should check current building codes and any related amendments. It should also be noted variances exist in how local jurisdictions interpret building code requirements and these differences tend to evolve over time in unpredictable ways. Hence, the energy guides are intended for early design stage decisions and professionals with knowledge of local interpretations should perform actual compliance calculations as the project nears permit application.

Code compliance paths

There are several paths designers can use to demonstrate compliance, including:

- prescriptive;

- trade-off; and

- whole-building energy modelling (performance path).

Prescriptive

This compliance path involves following the prescriptive requirements of each section of the code. The local building permit office may require project teams to complete and submit a checklist as part of the permit application.

Trade-off

This compliance path provides some flexibility by allowing certain elements within the same part of the code to be traded. For example, if the design calls for more window area than prescribed by limits in the code, one may be able to compensate by improving the insulation in the walls. Natural Resources Canada (NRCan) offers downloadable trade-off path calculation tools to help with this method.

Performance

This approach offers the most design flexibility. One must show the proposed design will not consume more energy than an equivalent building built to the prescriptive requirements of the code. For this compliance path, designers need to use a building-energy simulation tool.

As a result, buildings can be constructed with a wide range of window, roof, floor slab, and wall R-values. Thus, it is impossible to answer the question, “What R-value do I have to meet?”, because three primary compliance paths exist in all relevant building codes.

Climate

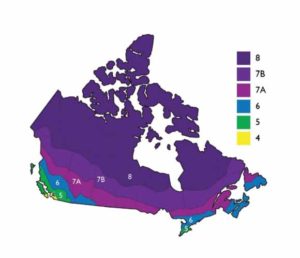

[4]

[4]Regardless of the code, the climate in which the building is to be located plays an important role in understanding what energy-saving measures are required. The most commonly used climate categories employ a similar zone numbering system as codes in the United States.

Occupancy

Many codes require higher thermal performance for enclosures of residential occupancy than nonresidential. This is based on the assumption nonresidential occupancy will have higher internal heat gains from lights, equipment, and high occupant density. The semi-heated category is provided in some codes to account for attached storage areas, garages, and other spaces not required to be kept at room temperature.

Assembly construction

Several assembly construction types deliver thermal performance quite different from their standard rated R-value because of implicit thermal bridging or thermal mass. To account for this, codes often have different requirements for mass walls (made of concrete or masonry), light-gauge steel framing, pre-engineered metal building systems, and wood framing.

As codes have moved closer to describing whole-wall R-values, the need to define categories for different assembly types has diminished and NECB no longer has a category for mass walls. Ontario’s SB-10, in force from January 1, 2017, has set the maximum U-value for all types of enclosures to the same values in one compliance option, but allows ASHRAE 90.1 mass benefits in another.

Prescriptive approach

[5]

[5]The simplest and oldest method of prescribing building energy performance is to specify the minimum required performance for each of the enclosure components in either U- or R-value (i.e. opaque walls, fenestration, roofs, below-grade components, etc.). The ‘installed insulation’ approach is the simplest and least flexible one. Designers choose the prescribed insulation R-value from a code table and create assemblies based on it. Today’s codes further prescribe how much must be installed within metal framing and the amount required to be installed as continuous insulation (ci) outboard of the metal framing.

This approach is very restrictive for design but has the advantage of relatively simple-to-read tables.

Trade-off analysis

Both simple and detailed trade-off methods are available. In the simple trade-off method, only enclosure components are traded off, whereas the detailed approach allows a more sophisticated analysis of solar gains for both reducing heating loads and increasing cooling loads. Like the prescriptive path, the trade-off approach requires meeting all mandatory parts of the code.

The simple enclosure trade-off method is very easy: provided the total heat loss/gain of the proposed building enclosure is equal to or less than a building built to the prescriptive minimum values, the building is code compliant. The total heat loss is simply calculated as the sum of the individual component areas times that component’s U-value.

Whole-building energy

Although specific characteristics of building enclosures (R-value, airtightness, and solar heat gain co-efficient [SHGC]) can reduce the demand for space heating and cooling, improvements to heating and cooling system efficiencies, lighting design, and mechanical ventilation systems can have a major impact on large commercial and institutional buildings. Thus, codes for larger buildings (e.g. ASHRAE 90.1 and NECB) often prescribe minimum performance levels for a wide range of mechanical equipment, lighting, and control systems.

Codes and thermal bridging

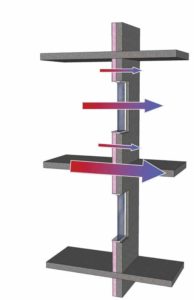

[6]

[6]Photo courtesy RES Precast

Based on research conducted by numerous organizations nationally and internationally, the effect of thermal bridging is now understood to play an important role, especially in well-insulated enclosures. The R-value often does not include the impact of specific thermal bridges such as floor slabs, structural anchors, and balconies. Thermal bridges, or at least the major ones, are generally intended to be included in tabulated U-values and code language is currently being strengthened to make this clear.

Ci is a common terminology encountered in modern prescriptive codes. It was added to code language to minimize thermal bridging, primarily in steel- and wood-framed enclosures. Ci is defined by ASHRAE 90.1 as:

insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

Calculating enclosure thermal performance

Many owners do not wish to provide more performance than the minimum code requirement. Hence, building professionals need to design buildings that ‘just meet’ these codes. This requires both an understanding of the code minimum performance and how to calculate the performance of the building enclosure. Other projects have different goals or a long-term perspective. In this case, designers are driven to make the best choices between many competing alternative enclosure systems and materials. In either case, an understanding of what level of thermal performance can be achieved is critical.

Definitions of R-value

[7]

[7]Photo courtesy Schokbeton Saramac

There are many different definitions of R-value, many of which were developed more than 20 years ago. The definition applied depends on the standard, code official, and the different needs of energy modellers and designers. However, the most important distinctions between the definitions involve how thermal bridging is considered.

When heat moves through an enclosure element, it flows through more than just the centre of the panel. Additional heat will flow through areas of steel or concrete penetrating the insulation layer. Such penetrations, termed thermal bridges, are inevitable and codes increasingly require designers to account for them when judging compliance.

Several types of R-values are reported in the industry or demanded by codes. These are explained below.

Installed R-value

The installed R-value, or nominal R-value, is simply the rated R-value of the insulation products in their installed condition (e.g. compressed batt insulation or not). The contribution of other materials is ignored.

Assembly R-value

The assembly R-value or centre-of-cavity is calculated by assuming the assembly is one-dimensional and simply adding the thermal resistance of all layers (e.g. in a precast concrete double-wythe insulated ‘sandwich’ panel, the outer concrete, insulation, inner concrete, and air films).

Clear-wall R-value

The clear-wall R-value (Rcw) accounts for the thermal resistance of the layers (assembly R-value). It also includes the two-dimensional effect of standard repetitive framing (e.g. steel studs and tracks) and conductive penetrations (e.g. floors).

Whole-wall R-value

The whole-wall R-value (Rww) includes Rcw and the thermal impact of any additional framing or fasteners at openings (e.g. windows and doors) as well as the effects of thermal bridges at changes in plane and other interfaces (e.g. foundation-to-above-grade-wall, wall-to-roof, and balconies) but excludes window area. For simplicity, sometimes the clear-wall R-value is used when whole-wall R-value should be (i.e. thermal bridging is ignored), but this approach can significantly overestimate the thermal performance of many commercial enclosure systems.

Overall

The overall R-value measures the performance of an entire enclosure type (such as wall or roof) and includes the combined effect of Rww and the heat loss through windows, doors, and curtain walls. It is important for understanding overall building performance and is implicit to the simple trade-off methods used to demonstrate compliance.

Effective R-value

The effective R-value is not a universal term, but rather is used to describe an R-value that may include some or all thermal bridging, air leakage, or even thermal mass. There is no one definition and it is not consistently used by major energy standards, but it is often the clear-wall R-value that is implied. Hence, the meaning of effective R-value varies depending on both the user of the term and the context.

Any of these R-values might also be reported as a U-value (U = 1/R). However, to add to the complexity, U-values almost always include the resistance of surface films, whereas R-values may or may not. Therefore, building professionals must be careful when interpreting requirements and be specific and precise when communicating required thermal performance.

Conclusion

[8]

[8]Photo courtesy CPCI

More insulation, better airtightness, and less thermal bridging will be required by future codes and green building programs regardless of the type of enclosure wall system considered. Some jurisdictions have indicated a desire for energy codes to provide a path to net-zero ready performance. Since building codes offer several compliance paths, there is no one R-value that is required for a specific building in a particular location. Increasingly, trade-off compliance paths are often chosen. This allows for lower, sometimes significantly lower, enclosure wall R-values than listed in prescriptive tables.

Precast concrete systems are well placed to respond to the demand for higher thermal performance, as a broad range of R-values can be provided by changing design details (For more information on the thermal performance of precast concrete enclosure systems, read “Meeting and Exceeding Building Code Thermal Performance Requirements for Precast Concrete Walls[9]” guide by RDH Building Science).

The “Meeting and Exceeding Building Code Thermal Performance Requirements for Precast Concrete Walls” guide presents the concepts at an introductory level for use in the early-stage design of precast concrete enclosure systems. Users should approach the guide by first calculating the clear-wall R-value for the system and floor-to-floor height under consideration, including thermal bridging of light-gauge steel framing and floor slab intersections. The insulation thickness and type can be adjusted as needed so the calculated value meets target design values or code minimums.

With prescriptive design, these values are sufficient, but alternate code compliance paths may make use of the values calculated for the selected enclosure design. The methods presented are not onerous to use and sufficiently accurate for early-stage design decisions. More detailed computer-based modelling will often be justified for complex systems, accurate results, and final design values.

The Canadian Precast/Prestressed Concrete Institute (CPCI) has worked with RDH Building Science and is launching the Precast Concrete Wall Thermal Performance Calculator[10]. This new, online tool provides designers, builders, and owners with a program to quickly estimate thermal performance of precast concrete wall systems using the methodology described in RDH’s thermal performance guide. For this software, the influence of dynamic thermal mass, which can only properly be assessed using computer programs for a specific building location, design, and occupancy schedule, has been excluded. As a result, the calculations can be considered conservative in this respect since dynamic thermal mass effects help reduce energy use. CPCI’s tool can inform early design stage decisions by allowing users to quickly select and view the performance of common walls with varying types and degrees of insulation.

[11]John Straube, PhD, P.Eng., is a principal at RDH Building Science and a cross-appointed faculty member in the School of Architecture and the Department of Civil and Environmental Engineering at the University of Waterloo. He is also a prolific writer and a noted public speaker. Straube’s leadership as a building scientist and an educator has been recognized with multiple awards, including the Lifetime Achievement Award in Building Science Education from the National Consortium of Housing Research Centers (NCHRC). He can be reached at jfstraube@rdh.com[12].

[11]John Straube, PhD, P.Eng., is a principal at RDH Building Science and a cross-appointed faculty member in the School of Architecture and the Department of Civil and Environmental Engineering at the University of Waterloo. He is also a prolific writer and a noted public speaker. Straube’s leadership as a building scientist and an educator has been recognized with multiple awards, including the Lifetime Achievement Award in Building Science Education from the National Consortium of Housing Research Centers (NCHRC). He can be reached at jfstraube@rdh.com[12].

[13]Brian J. Hall, BBA, MBA, is the managing director of the Canadian Precast/Prestressed Concrete Institute (CPCI), the vice-chair of the Royal Architectural Institute of Canada (RAIC) Foundation, and a board member of the Athena Sustainable Materials Institute. He is one of the authors of the institute’s sustainability strategy that includes the development of the CPCI Precast Concrete Life Cycle Assessment, the Sustainable Plant Program, and the CPCI North American Environmental Product Declaration for precast concrete. Hall can be reached at brianhall@cpci.ca[14].

[13]Brian J. Hall, BBA, MBA, is the managing director of the Canadian Precast/Prestressed Concrete Institute (CPCI), the vice-chair of the Royal Architectural Institute of Canada (RAIC) Foundation, and a board member of the Athena Sustainable Materials Institute. He is one of the authors of the institute’s sustainability strategy that includes the development of the CPCI Precast Concrete Life Cycle Assessment, the Sustainable Plant Program, and the CPCI North American Environmental Product Declaration for precast concrete. Hall can be reached at brianhall@cpci.ca[14].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/DSC_3853.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/Thermal-bridging.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/08_019_130.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/Map.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/July-4-2007-176.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/One-King-MagCover-2.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/Tours-Lépine-061.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/Web-site-108.jpg

- Meeting and Exceeding Building Code Thermal Performance Requirements for Precast Concrete Walls: http://www.cpci.ca/en/resources/technical_publications

- Precast Concrete Wall Thermal Performance Calculator: http://www.cpci.ca

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/11/Straube-John-615sq.jpg

- jfstraube@rdh.com: mailto:jfstraube@rdh.com

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2019/01/Brian-Hall-1.jpg

- brianhall@cpci.ca: mailto:brianhall@cpci.ca

Source URL: https://www.constructioncanada.net/assessing-thermal-performance-and-resiliency-of-contemporary-buildings/