Assessing mass concrete with thermal control plan

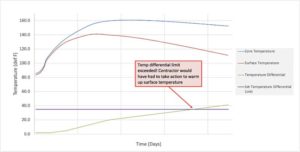

The development of a performance-based TCP may require additional pre-planning, compared to a traditional plan. However, the cost savings in the field far outweigh any of the additional engineering costs. Figure 2 shows an example of a typical concrete temperature curve. For both the core and the surface, the temperatures typically climb and peak around the first two days, with the core temperature exceeding the surface temperature. The differential between the two will start to rapidly increase as the surface temperature starts to cool significantly faster than the core. It is common to see the temperature differential peak around the third or fourth day.

Assume the contractor is using a TCP with a set 19 C (35 F) temperature differential. To avoid breaching the threshold, the contractor would potentially need to add blankets/insulation to the exterior surface to minimize the heat loss. In other cases, the contractor may even be required to heat the surface using propane or diesel heaters. In either case, there are significant costs to these operations—potentially thousands of dollars per pour (Figure 2).

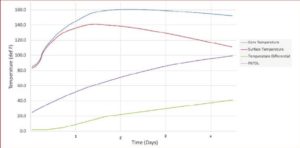

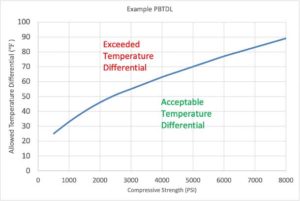

Consider the same scenario, but assume the contractor is using a PBTDL. In this situation, the concrete gains strength, and the allowed temperature differential also increases and stays safely above the actual measured differential. This avoids the headaches, costs, and environmental impact with heating the surface of the element (Figure 3).

Conclusion

The set temperature differential method of placing and curing concrete can be easier to understand and simpler to implement. However, as awareness increases with the limitations of the 19 C (35 F) set temperature differential, coupled with the technology improvements for the concrete sensors, the use of a PBTDL approach is rapidly gaining popularity. Contractors can access the temperature data remotely and in real time. This means they do not need to be on-site to see their temperature or strength data. They can access the data remotely, providing critical information on concrete temperatures, temperature differentials, strength, and allowed temperature differential. This advantage allows contractors to be more proactive from both a quality control (QC) and operational standpoint.

A PBTDL approach can require more upfront engineering, but for proactive contractors that have mass concrete projects, the operational, environmental, and time savings can be impactful. Contractors, engineers, and building owners who embrace the benefits of using PBTDL will reap the rewards now and in years to come.

A PBTDL approach can require more upfront engineering, but for proactive contractors that have mass concrete projects, the operational, environmental, and time savings can be impactful. Contractors, engineers, and building owners who embrace the benefits of using PBTDL will reap the rewards now and in years to come.

Eric Van Dixhorn serves as technical sales director at Brickeye, a leader in advanced IoT solutions for construction and industrial applications. Based in Colorado, he holds a bachelor’s degree in civil engineering and has a background in construction, with a specialty in heavy-highway and infrastructure construction. Previously serving as vice-president of engineering at NITROcrete, Dixhorn has more than a decade of experience in the industry.