Assessing mass concrete with thermal control plan

Historically, most specifications and TCPs follow ACI 301 with respect to the temperature restrictions. In many cases, a thorough analysis of the design and the corresponding mix constituents allows the engineer to offer less restrictive requirements, especially when it comes to the temperature differential, allowing for an increase of the allowable ΔT beyond 19 C (35 F).

The purpose of limiting the temperature differential within the element is to avoid thermal cracking that can result from a large temperature difference between the centre and exterior surfaces. Temperature differentials lead to internal stresses, and if the concrete (especially in the first few days of curing) is not able to resist the temperature-induced stresses, cracking will result. The cracking can result in long-term structural and durability issues.

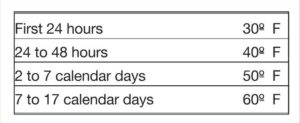

ACI’s ΔT limit of 19 C (35 F) is safe, conservative, and simple to implement, which is why this limit has typically been the standard for most projects. However, the main shortcoming of this restriction is that it does not account for the strength the concrete gains while it cures. Having recognized this shortcoming, numerous agencies and institutions have implemented a temperature differential approach that is based on time. This method is typically referred to as a stepped temperature differential limit (Figure 1).

Although the stepped approach is an improvement compared to the set limit, the specifications are making assumptions on the concrete’s strength as it cures. Thankfully, there is another method: the performance-based temperature differential limit (PBTDL).

Performance-based temperature differential limit

The PBTDL method provides a temperature differential limit that is directly tied to the concrete’s compressive strength. It completely replaces the 19 C (35 F) temperature differential limit. Essentially, the allowed temperature differential will increase as the concrete gains strength. Initial testing on the mix is required to determine material properties, such as elastic modulus, tensile strength, and the coefficient of thermal expansion. These properties are used to develop a chart that provides the temperature differences the concrete can resist without resulting in thermal cracking.

The strength of in-place concrete is determined through the maturity method, which is an ASTM standard (ASTM C1074: Standard Practice for Estimating Concrete Strength by the Maturity Method) that correlates the temperature history to strength. This means, if the temperature of the concrete is being tracked while it is curing, the maturity method can accurately determine the real time in-place strength.