Applying the carbon equation to insulating glass units (IGUs)

The impact of climate loads

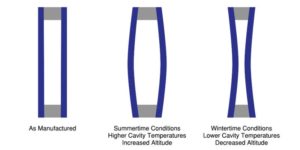

Changes in environmental conditions, such as barometric pressure, cavity temperature, and elevation compared to those under which the IGU was made, create a difference in pressure between the gas in the cavity and the outside environment. For example, in summer, the sealed IGU cavity often becomes hotter than when it was manufactured, increasing the cavity pressure. In winter, the cavity becomes colder, reducing the pressure. These pressure differences between cavity and the outside air are typically equalized, or partially equalized, through deflection of the glass lites (Figure 6). In winter in cold climates, it is typical to observe negatively deflected IGUs in buildings, as it indicates the unit is still sealed.

However, in smaller, stiffer IGUs, where glass lites are less flexible, they are not able to equalize the environmental loads through deflection as much. As a result, more load is focused on the edge seal, which causes the sealant material to stretch as the edges of the glass move apart to support pressure equalization.

The stiffness of the silicone secondary seal and spacer control the resultant strain on the extension of the primary sealant under such climate loads, which in turn controls the moisture vapour transmission. More primary sealant extension means higher moisture vapour and gas transmission.

This means, (i) the control of the IGU edge seal extension is key to managing service life, and (ii) smaller and/or stiffer IGUs are at a greater risk of experiencing a higher primary seal extension than larger IGUs of the same configuration.

Factors increasing IGU edge seal forces include:

- Large cavities

- Triple-pane configurations

- Thick lites

- Laminated glass

- Bent glass

- Narrow glass

- High in-service temperatures

- Changes in elevation compared to the IGU fabrication location

Current practice for IGU design qualification

The current practice for IGU manufacturers is to qualify the durability of the performance of an edge seal design according to standardized weathering standards such as:

- ASTM E2190, Standard Specification for Insulating Glass Unit Performance and Evaluation (North America).

- Canadian General Standards Board CAN/CGSB 12.8, Insulating Glass Units (Canada).

- EN 1279-2, Glass in Building. Insulating glass long-term test method and requirements for moisture penetration used in Europe.

These tests standardize test unit size, glass thickness and cavity size along with temperature conditions. As a result, they deliver a maximum standard climate induced edge load of 0.64-0.79 N/mm (depending on the test standard) during the test.

There is also data from the Insulating Glass Manufacturers Alliance’s (IGMA’s) 25-year field correlation study, which shows the failure rate of IGUs meeting the equivalent of the ASTM E2190 standard (its predecessor standard ASTM E774, class CBA) was 3.6 per cent.4