Applying coating systems for labs

by Elaina Adams | July 1, 2012 10:45 am

[1]

[1]By David Walker, BBA, MBA, NACE, and Greg Pope, NACE

The proverb, “cleanliness is next to godliness,” applies to research facilities where walls, ceilings, and floor surfaces must be kept in a neutral, sterile environment to prevent bacteria or other micro-organisms from affecting testing protocols.

Over the past decade, more than 93,000 m2 (1 million sf) of spray-applied or mat lay-up fibre-reinforced epoxy wall coatings have been used at sterile animal laboratories, vivariums, and pharmaceutical and medical facilities across Canada and the United States. Common substrates where the coating systems are applied include high-impact gypsum wall board, cement board, concrete masonry units (CMUs), and poured or precast concrete. (See ASTM D3730-10, Standard Guide for Testing High-performance Interior Architectural Wall Coatings).

Fibreglass-reinforced coating systems enhance the integrity of the substrate to which they are applied, providing superior resistance to impact, thermal shock caused by daily high-pressure steam-cleaning, along with the detergents and disinfectants that sanitize surface areas.

[2]

[2]Photo courtesy Tnemec Company

Coatings create a seamless, monolithic surface, unlike tiles or panels, which have grout lines, anchor points, and seams in which dirt can accumulate and bacteria can grow. These penetration areas resist disinfection and also create pathways to spaces behind the wall for micro-organisms and insects to infiltrate. When it comes to animal laboratory facilities, a preference for seamless wall, floor, and ceiling coating systems is cited in published guidelines from National Institutes of Health (NIH), Canadian Council on Animal Care (CCAC), and National Research Council (NRC).

Vivarium design

Criteria for vivarium design and engineering of walls, ceilings, and floors is included in CCAC’s Guidelines On: Laboratory Animal Facilities—Characteristics, Design, and Development. The resource emphasizes the need for all materials and finishes to be designed to facilitate the sanitation process.

The publication suggests materials and finishes be durable, impervious, and resistant to water and chemicals used in their sanitation. Additionally, they must be able to withstand physical damage by items used in the facility, such as cage racks, carts, and various cleaning equipment. Ledges, crevices, cracks, and unsealed service penetrations that can harbour dirt and vermin should be eliminated whenever possible, and all hollow doors must be filled or completely sealed.

Walls should be covered with an impervious coating that withstands frequent cleaning and chemical disinfectants and has been tested for high stain resistance. The walls need to be free of cracks, and all pipe and service sleeves should be sealed to exclude vermin. For ease of cleaning and disinfection, the walls must be seamless and the floor coved to the walls after installation of wall systems.

[3]

[3]Photos © David Walker. Photos courtesy Avid Protective Products

Seamless urethane flooring with an integral cove base is the most common flooring used, especially in animal rooms. It is durable, impervious to many chemicals and solvent-based products, and easily cleaned. While there is possibility for slip resistance to be created, care must be taken not to have the surface too rough since this reduces the floor’s lifespan and makes sanitation more difficult. Input from those who will use these spaces is critical to achieving the desired finish and safety.

As with floors and walls, ceilings must be resistant to frequent washing and disinfection protocols; however, they are not subject to the same wear and tear. The preferred substrate for ceilings is moisture-resistant drywall that is well-sealed at all ceiling-wall joints and penetrations. It should be coated with a two-component 100 per cent solids epoxy finish and a waterborne urethane as to maintain little to no volatile organic compounds (VOCs) during construction and maximize performance of the overall coating system. A seamless ceiling should be provided in all animal holding, procedure rooms, and cage wash locations.

Construction guidelines for walls, floors, and ceilings are also included in NRC’s Guide for the Care and Use of Laboratory Animals, which specifies ceilings and floors should be “smooth, moisture-resistant, non-absorbent, and resistant to damage from impact.” The document emphasizes durable, moisture-proof, fire-resistant, seamless materials are most desirable for interior surfaces. These should also be highly resistant to the effects of cleaning agents, scrubbing, high-pressure sprays, and impact.

[4]

[4]At two Canadian university research facilities, specifications called for monolithic, fibreglass-reinforced coatings for walls, ceilings, and floors in laboratory animal facilities. The specified 100 per cent solids epoxy and waterborne urethane technology was solventless, virtually odourless, and compliant with standards in Canada and the United States.

University of Western Ontario

At the University of Western Ontario’s (UWO’s) Modular Animal Care Facility (MACF), fibre-reinforced wall coating systems were specified for high-impact gypsum wall board, CMU, and poured concrete wall surfaces. Each substrate required specialized primers and parge coatings as a base over which high-performance coating systems were applied. An odourless cementitious acrylic masonry filler was applied to CMU walls, an aggregate-reinforced surfacer was applied to poured concrete, and a 100 per cent solids epoxy surfacer was used on drywall nail heads and seams.

Located in London, Ont., the multi-story MACF is divided into four zones that contain mechanical equipment, holding rooms, procedure and lab space, cage washrooms, and animal storage. The holding and research facility adjoining the university’s hospital consists of four distinct modules to house pigs, primates, pregnant sheep, and mice. A 100 per cent solids fibreglass mat-reinforced epoxy coating system was specified for the holding rooms and high-risk, animal-exposed areas, while a non-reinforced system was used for all interior overhead gypsum wall board and remaining wall areas.

[5]

[5]Image courtesy Tnemec Company

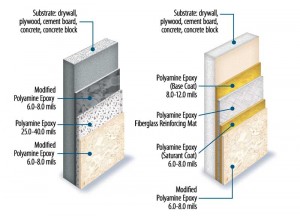

The critical areas required placing a fibreglass reinforcing mat into a bedding coat of 100 per cent solids polyamine-cured epoxy roller-applied at approximately 0.2 to 0.3 mm (8 to 12 mils) dry film thickness (DFT) while still wet. When placing the fibreglass mat into the bedding coat, its edges were butted together rather than double-cut after placement. Broad knives, trowels, or wallpaper brushes were used to smooth the fibreglass mat and force any air pockets out from behind it.

A second coat of 100 per cent epoxy resin was roller-applied at approximately 0.2 to 0.3 mm DFT to completely wet-out and saturate the reinforcing mat. After the coating had cured hard, it was pole-sanded with 50-grit resin-coated sandpaper to remove protruding fibreglass strands or imperfections. For additional abrasion resistance and enhanced colour and gloss retention, a topcoat of low-odour, low-VOC ceramic-modified waterborne polyurethane was applied.

Interior overhead drywall and less critical wall areas in the facility received the same coating system, but without the fibreglass mat reinforcement. The primary reason for using a 100 per cent solids epoxy coating system over high-impact drywall and wallboard is to offer additional protection against physical abuse or from frequent cleaning typically performed with mild chemicals, rags, or sponges. Such applications are usually limited to dry environments where moisture is unlikely to come in contact with the drywall, wallboard, or joint-treating compound, which could result in a breakdown of the substrate.

[6]

[6]Photos © David Walker. Photos courtesy Avid Protective Products

Attention to details with choice of substrate is important at this juncture, as the cost of redoing critical animal areas is too high while research is being performed on animals operating within specific testing guidelines. The wrong substrate and coating system selections could jeopardize months of testing protocols that have been established for animals in these spaces.

Attention to metal doors and window frames and how they are detailed to the wall system was also important for MACF. Leaving leading edges of door frames exposed for clean termination is required to maintain cleanliness standards of the facility. These locations were coated with two coats of waterborne urethane as applied to the wall finish. All metal doors and window frames in the facility were coated with two to three coats of epoxy. A modified polyamine epoxy was trowel-applied to the flooring at 6.4-mm (¼-in.) thickness, followed by a coat of polyamine epoxy. Operating room floors also received a topcoat of an extremely hard, chemical-resistant aliphatic polyester polyurethane for added stain and chemical resistance.

University of Toronto

A fibreglass mat-reinforced coating system was specified for the walls of critical research areas at University of Toronto’s (U of T’s) Terrence Donnelly Centre for Cellular and Biomolecular Research. The award-winning facility offers a collaborative laboratory and classroom environment dedicated to research in bioengineering and disease.

[7]

[7]Walls in critical research areas were coated with a fibreglass mat-reinforced system roller-applied over an epoxy-modified cementitious resurfacer and prime coat of polyamine epoxy. The remainder of the block walls and cement-board ceilings were coated with waterborne cementitious acrylic filler and finished with two to three roller-applied coats of a high-build, low-odour waterborne acrylic epoxy. All voids in the face of the block and mortar joints were filled to create a smooth, seamless surface before the protective coating system was applied.

In the facility’s cage washroom area––which is exposed to frequent steam-cleaning, wash-downs, and chemicals––the fibreglass mat-reinforced wall coating system received a topcoat of an extremely hard, chemical-resistant urethane. Wash-down room floors were coated with a polyurethane modified concrete topping designed to perform under extreme temperature changes, followed by a clear novolac epoxy, and a topcoat of extremely hard clear urethane for increased abrasion and chemical resistance.

Surgery room floors received a layer of modified polyamine epoxy, trowel-applied at 6.4-mm thickness, followed by a durable polyamine epoxy used to seal the mortar and build thickness. An extremely hard, chemical-resistant polyurethane finish was applied as a topcoat for added abrasion resistance and colour and gloss retention.

The Donnelly Centre has been recognized with a Royal Institute of British Architects (RIBA) International Award, the Ontario Association of Architects (OAA) Award of Excellence, and the Business Week/Architectural Record Award, recognizing the most successful collaborations between architects and clients.

[8]

[8]Surface preparation

Applying spray-applied or mat lay-up fibre-reinforced wall coating systems over common wall substrates requires proper surface preparation. Cement board is commonly encountered in research facilities and hospitals, such as Tufts Medical Facility in Boston, Mass., where a fibreglass mat lay-up coating system covers more than 3700 m2 (40,000 sf) of wall surface.

Since the face of cement board is porous, double priming with a high-solids moisture-tolerant polyamine-cured epoxy helps smooth the substrate to create a pinhole-free surface. Joints and screw holes also need to be properly treated using 100 per cent solids epoxy filler and surfacer or epoxy-modified cementitious mortar.

Both poured and precast concrete substrates should be prepared in accordance with Society for Protective Coatings (SSPC) SP13/NACE International No. 6, Surface Preparation of Concrete, by abrasive blasting or mechanically abrading the surface to remove laitance, form-release agents, curing compounds, hardeners, sealers, and other contaminants. (This comes from NACE Publication 6G191, Surface Preparation of Contaminated Concrete for Corrosion Control. Also see SSPC’s Guide No. 11, Guide for Coating Concrete). Laitance is a thin, weak layer of aggregate fines and non-reactive cement residue loosely bonded to the substrate. When coated over, this surface defect can compromise the coating system’s long-term adhesion. Removing laitance is critical before the application of any coating.

Concrete masonry units—commonly specified for walls in vivarium and animal care environments in the biomedical field—have surface voids and mortar joints that need to be filled before applying a fibreglass mat-layup system. This can be achieved through use of 100 per cent solids epoxy resurfacing material or modified cementitious mortar to parge the CMU’s entire surface. Depending on the block’s porosity and depth of the tooled joints, the parge coat is applied at an approximately 1.5-mm (1⁄16-in.) nominal thickness.

At the Merck Research Facility in Boston, Mass., a fibreglass mat-reinforced coating system covers more than 37,000 m2 (400,000 sf) of CMU substrate. Similar wall coating systems were used on CMU surfaces on nearly 16,300 m2 (175,000 sf) at the Genetics Institute’s Wyeth Building T Project, 7900 m2 (85,000 sf) at the Massachusetts Institute of Technology (MIT) Brain Cognitive Research Facility, and 3716 m2 (40,000 sf) on the MIT Koch Research Building in Cambridge. Brock University in St. Catharines, Ont., is currently installing these coating systems as well.

David Walker, BBA, MBA, NACE, is the owner of Avid Protective Products, a representative of Tnemec Company in Oakville, Ont. With more than 20 years of experience in the protective coatings industry, he is a NACE International-certified coating inspector and belongs to both the Society of Protective Coatings (SSPC) and the American Water Works Association (AWWA). Walker serves on many AWWA coating standards committees. He can be contacted via e-mail at avid@bell.net.

Greg Pope, NACE, is a coating consultant at Righter Group Inc., a representative of Tnemec Company in Wilmington, Mass. As a NACE International Level 2 coating inspector, he has more than 30 years in the coating industry and works with technologies for the architectural, water, wastewater, hydropower, and petrochemical refining industries. Pope’s technical expertise includes detailed knowledge of specification writing, surface preparation, and material application methods. He can be reached at gpope@rightergroup.com.

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Finishes_Toronto-CBR-2.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Finishes_Dog-Cage-Walls.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Finishes_Ontario-Animal-Care-1.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Finishes_Ontario-Animal-Care-2.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Finishes_Stranlok_A.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Finishes_Toronto-CBR-1.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Fibreglass-1-2.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/12/Finishes_Toronto-CBR-3.jpg

Source URL: https://www.constructioncanada.net/applying-coating-systems-for-labs/