Advancing bridge performance with UHPC

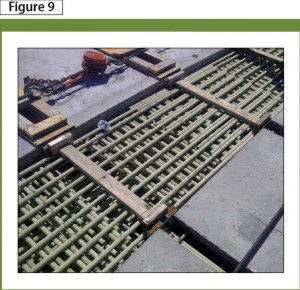

Design of the longitudinal moment connection was extremely complicated as it entailed joining the box girders not only to each other, but also to the transverse UHPC T-beam supporting them (Figure 9). The design had to accommodate the precast elements into a detail that was typically cast-in-place. By using UHPC and prestressing the concrete, the T-header beam could be designed in precast and match the depth of the box girders.

To connect the precast elements and provide a monolithic structure, UHPC was used to fill the joint in the field. The production of these monolithic elements was a major contributor toward optimizing the bridge’s overall efficiency.

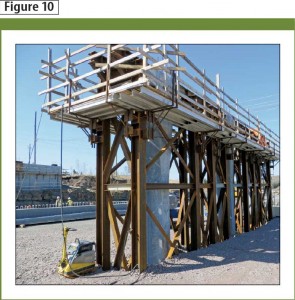

As the inverted T-beam was designed only for the loads as a composite member, shoring towers were constructed to take the dead load of the girders during erection and until the UPHC had been placed and cured in the field-cast joint (Figure 10).

Conclusion

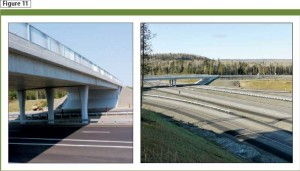

The Hodder Avenue Underpass is a ‘leading-edge’ project and the first bridge structure in North America to incorporate an ultra-high-performance concrete pier cap, shell-pier column, and field-cast connections, together with precast HPC box girders, parapet walls, and approach slabs (Figure 11). The project demonstrates when UHPC is used for both precast elements and field-cast connections that the result can be durable and esthetically pleasing.

By employing the material’s combination of superior properties, bridge know-how is advanced, construction speed is accelerated, and long-term durability improved, with additional benefits that include increased structural capacity, lowered maintenance, reduced joint size and complexity, improved deck continuity, extended life, and an elimination of post-tensioning. The result is a resilient bridge structure built to last.

Raymond Krisciunas, P.Eng., is the head structural engineer for the Ministry of Transportation Ontario (MTO) Northwestern Region. He received his bachelor of engineering science degree from the University of Western Ontario in 1978, and joined MTO in 1985. Based in Thunder Bay, Ont., Krisciunas can be reached at ray.krisciunas@ontario.ca.

Peter J. Seibert is the technical director for Ductal, Lafarge’s ultra-high-performance concrete (UHPC). Based in Toronto, he is responsible for the manufacturing, supply chain, quality control, and technical aspects of Ductal in North America. Seibert obtained his bachelor of civil engineering from the University of Toronto in 1996, a master’s from Queen’s University in 1998, and an MBA from Wilfrid Laurier University in 2003. He can be contacted via e-mail at peter.seibert@lafarge-na.com.

Philip D. Murray, M.Eng., P.Eng., is a vice-president at Hatch Mott MacDonald Ltd. Based in Mississauga, Ont., he is the firm’s subdivision manager of provincial infrastructure (including their Thunder Bay office). He obtained his bachelor’s degree in civil engineering from Queen’s University in 1994, and a master’s in engineering from the University of Toronto in 2000. Murray can be reached at philip.murray@hatchmott.com.