Advances in curtain walls: Fibre-reinforced polymer technology

Component options

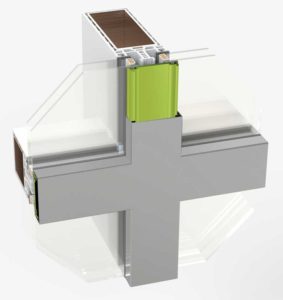

There are several key areas of the curtain wall framing where FRP materials can be used as a solution.

Pressure plates

Pressure plates are fastened to the outside of mullions in a curtain wall system to hold the glass in place. FRP pressure plates can be custom designed to fit into a fabricator or original equipment manufacturer’s (OEM’s) proprietary fenestration system.

Commercial projects using FRP pressure plates will notice significant thermal benefits because of the material’s low thermal conductivity rate, especially when compared to aluminum. In addition to outperforming aluminum, FRP pressure plates provide more compressive and flexural strength head-to-head against other materials often used for this purpose, including plastics or polyamide.

Structural thermal struts

Structural thermal struts are used for a thermal break between windows, doors, and curtain walls and can be created from FRP materials to deliver a solution that is better than old, outmoded options. FRP struts replace pour and de-bridge thermal fills and offer added structural strength, flexibility, and faster assembly for workers. They also perform well with polyurethane adhesives.

Additional curtain wall components

In a single, custom solution, FRP curtain wall components can be used by specifiers to meet the needs of an array of architectural designs for structural support and the energy efficiency of the overall building and curtain wall system they are used on.

FRP components also remain impermeable to virtually any reasonable natural heat or cold with temperature resistance ranging from -40 C (-40 F) to more than 93 C (200 F) for suitability in any climate in Canada or the U.S.

FRP curtain wall components can work with both primary types of curtain wall construction methods/designs: unitized or stick-built systems.

There are no current standards for using fibreglass in architectural aluminum, making it more difficult to specify. Curtain wall designers are beginning to see that using FRP materials in their systems can significantly improve the thermal performance of their designs. However, most designers are still not using these products. The responsibility is on FRP manufacturers to promote the technology to designers and architects. Recently, there are more large curtain wall manufacturers adding these products to their designs. In fact, some manufacturers have created entire window walls out of the material.

According to the Fenestration & Glazing Industry Alliance (FGIA),1 curtain wall sightlines are typically 57.15- to 76.3-mm (2.25- to 3-in.) wide, with a system depth of approximately 152.4 to 254 mm (6 to 10 in.). Regardless of which construction type or dimensions are selected for the curtain wall, FRP manufacturers can recommend how to best integrate these components into new or existing curtain wall systems to expedite the production process for the fabricator and the installation process for glazing contractors.