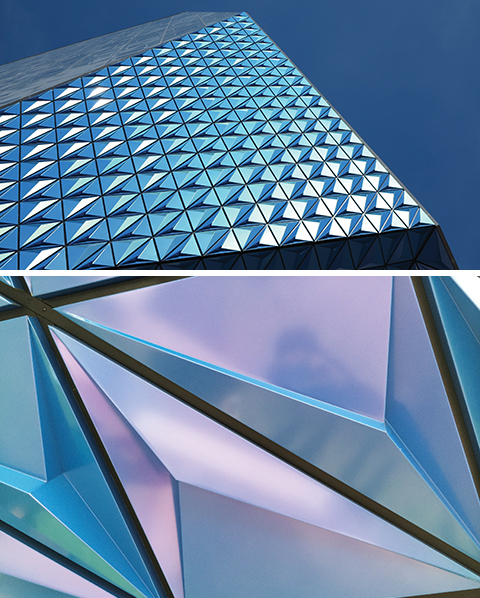

Adding flair and functionality to glass with digital printing

Benefits and limitations

There are many benefits that come with the digital printing process. A few of the most frequently cited are cost savings, design flexibility, and repeatability. The cost savings over silk-screening occur when there are a large number of screens required relative to the final number of units that need to be produced. There are also no storage costs with digital printing that are usually associated with screens, as the files are stored electronically.

Design flexibility is achieved by allowing for custom images consisting of multiple colours. Micro-lines, micro-dots, and dual images add to the flexibility offered by digital printing. Dual images consist of an image viewed from one side of the glass with a different image viewed from the other side of the glass, even though both images are printed on the same surface of the glass. Finally, since the design files are stored electronically, replacements and reproductions can be produced months and even years later with dependable results.

However, if the print is exposed to UV light, it may fade over time. This makes precisely matching replacements more challenging. Colour adjustments may need to be made to the electronic art file before printing to ensure a satisfactory replacement.

There are also limitations to the digital printing process that must be taken into consideration to determine if digital printing is the appropriate choice for the project. Calculating performance data across the façade can prove to be challenging. As mentioned, the various colours of ink can transmit light and solar energy at different levels. However, minimum performance levels can be calculated because the performance characteristics of the glass substrate, any coatings applied to the digital print or glass substrate, and other enhancements are already known.

Matching the colour of the final printed image to the vision of the architect or designer can also pose a challenge. The amount of light being transmitted and reflected during a sunny versus cloudy day, time of day, and interior lamp colour temperatures and lumens, all affect the way the image is perceived at different times.

Additionally, applying a coating over the print may slightly alter the vibrancy of the colours. The choice of substrate can also cause the colours to appear different than the design. For example, regular clear glass may impart a green hue to the image while a low-iron glass substrate helps subdue the green shift effect. As each printed image is different in terms of colour, design intent, and the way the image is constructed within the designer’s software, the adjustments necessary to compensate for coating and substrate choices will be different for each printed image. All these issues must be taken into account when designing an image using digital printing.

Designed by Toronto-based Ziedler Partnership Architects and Snøhetta (Olso), Ryerson University’s 5000-m2 (53,820-sf) Student Learning Centre utilized more than 3000 digital printed glass panels, covering 60 per cent of the building. Digital printing on the façade (shown on this magazine’s cover) helped contribute to the building being designated as LEED-certified under the Leadership in Energy and Environmental Design rating program, with Silver currently pending.