Acoustical ceilings and fire safety

While the tests to determine FSC and SD ratings only measure an individual product (e.g. a ceiling panel), procedures to determine fire resistance ratings are true ‘system tests’ that include all components in a roof/ceiling and floor/ceiling assembly. This means every material used in the construction, such as bar joists, acoustical panels, and steel fireproofing are included. A malfunction of any components in the assembly can result in failure of the fire resistance test because all components are tested as a complete system.

Fire resistance tests—such as CAN/ULC-S101, Fire Endurance Tests of Building Construction and Materials—measure the time an assembly contains a fire and is able to slow the temperature rise of building elements in the space above the ceiling so as not to ignite combustible material on the unexposed side of the assembly. The resultant fire-resistance-rated assembly and its time rating are then published in the UL Fire Resistance Directory or other such resources.

The UL Fire Resistance Directory provides criteria for the specific products installed in each component of the assembly. It also defines the specific manufacturer, type, size, and thickness of the ceiling panel and suspension system that must be used, as well as all other assembly elements. Any deviation results in a violation of the assembly’s design, and then in a loss of its fire resistance rating.

Fire resistance assembly requirements

Only acoustical ceiling panels specifically designed and tested as part of a fire-resistance-rated assembly can be used in a fire-resistance-rated floor/ceiling or roof/ceiling assembly. They are always identified as such, usually on the back of the panel.

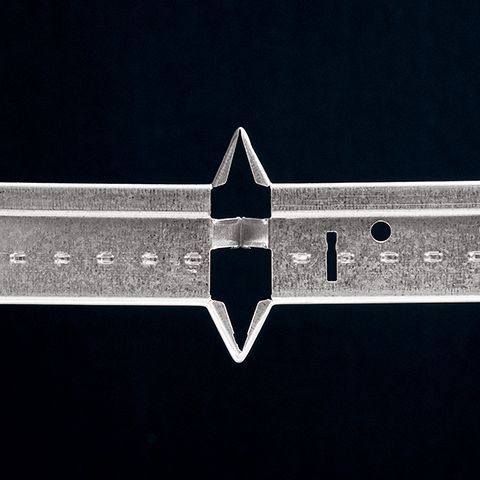

Similarly, only suspension systems specified in the UL or other testing laboratory designs can be employed. Helping maintain the structural integrity of the ceiling, these systems are usually identified by the presence of expansion-relief notches in the main beams. If the notches are absent, the grid will expand and distort as it becomes hotter, eventually allowing the ceiling panel to drop into the space below.

Another key component of a fire-resistive assembly is the weight of the ceiling panel. Fire-rated panels must weigh a minimum of 4.5 kg/m2 (1 lb/sf). This will offset the effect of hot fire gases, lifting a lighter ceiling panel and pushing it out of place, resulting in lost protection.

In many building codes and UL-tested and listed system designs, hold-down clips are required on each panel—they must be installed if panels weigh less than the specified amount. However, installation of hold-down clips requires additional time, labour, and costs, and there is no quick assurance the clips are always installed in the proper position.

Smoke barriers, smoke partitions

The fire safety requirements for an acoustical ceiling can vary depending on the specific building’s use, occupancy, and construction details.

For example, smoke barriers and smoke partitions, frequently equated with corridor walls and ceilings, are two types of construction often found in hospitals. Smoke barriers are designed to completely stop the movement of smoke from one space to another, while smoke partitions are designed to limit the passage of smoke from one space to another, but not stop it completely. As a result, smoke partitions are not intended to provide a safe haven that is completely free of smoke. (A suspended ceiling can be part of a smoke partition, but not part of a smoke barrier.)

The function of each requires smoke barriers to have much more stringent requirements than smoke partitions. For example, smoke barriers must extend from the floor to the underside of the above floor or roof deck assembly. The wall must extend through any concealed spaces such as those above suspended ceilings, and through any interstitial structural and mechanical spaces. Additionally, any penetrations and joints must be fire stopped.

Smoke partitions can extend from the floor to the underside of a monolithic or suspended ceiling system as long as:

- the ceiling system forms a continuous membrane;

- a smoke-tight joint is provided between the top of the partition and the bottom of the suspended ceiling; and

- the space above the ceiling is not used as a return air plenum.

The space above a ceiling is often used as a return air plenum in many types of commercial buildings, meaning exhaust air from the room below is moved from the space, through the plenum, and then to ductwork leading to the central HVAC system.

In hospitals, however, this is rarely the case—the sheer number of service lines running through the space, and the need to minimize the chance of any airborne infection being spread through the plenum to other parts of the facility, prevent it.