Acoustic considerations for metal ceilings

By Isabelle Champagne, CTR

Whether specifying acoustic ceilings for classrooms, healthcare facility inpatient areas, or a business centre’s offices, it is important to remember the goal is ‘clarity,’ rather than ‘silence.’ Some spaces seek to project sound across a large distance, while others work to maintain privacy within a small space. Regardless of the application, a thoughtful selection of ceiling systems can contribute to a balanced design that mitigates unwanted noises and optimizes occupants’ comfort with desirable sounds and speech intelligibility.

Made of steel or aluminum (or a combination thereof), suspension systems support the ceiling panels. One of its structural components, the T-bar, must carry loads such as light fixtures, diffusers, and wires. For that reason, some installations require heavy- or intermediate-duty main tees. When used in conjunction with the appropriate cross-tees, these products allow the entire system to meet esthetic, acoustic, fire, life safety, and seismic requirements.

ASTM C635, Standard Specification for the Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings, and ASTM C636, Standard Practice for Installation of Metal Ceiling Suspension Systems for Acoustical Tile and Lay-in Panels, outline the structural properties of metal ceiling suspension assemblies, along with the proper installation technique for these systems with various infill panels. Additional load tables and seismic information can be requested through ceiling systems’ manufacturing companies.

Standard acoustical ceiling panels, better known as ‘tiles,’ are typically mineral fibre, fibreglass, or perforated metal or wood. They provide a finished and accessible ceiling plane; while providing varying levels of sound absorption within any project’s budget.

Metal panel systems with perforations and acoustical backers offer efficient acoustical ceiling options. These types of metal ceilings include aluminum and steel panels in different shapes and dimensions, with various types of metal suspension.

For example, a car dealership’s waiting lounge should be both elegant and comfortable for customers. A metal ceiling system with T-bar suspension system can provide the right esthetic touch, while managing the acoustics for a clean and quiet environment.

Acoustic considerations

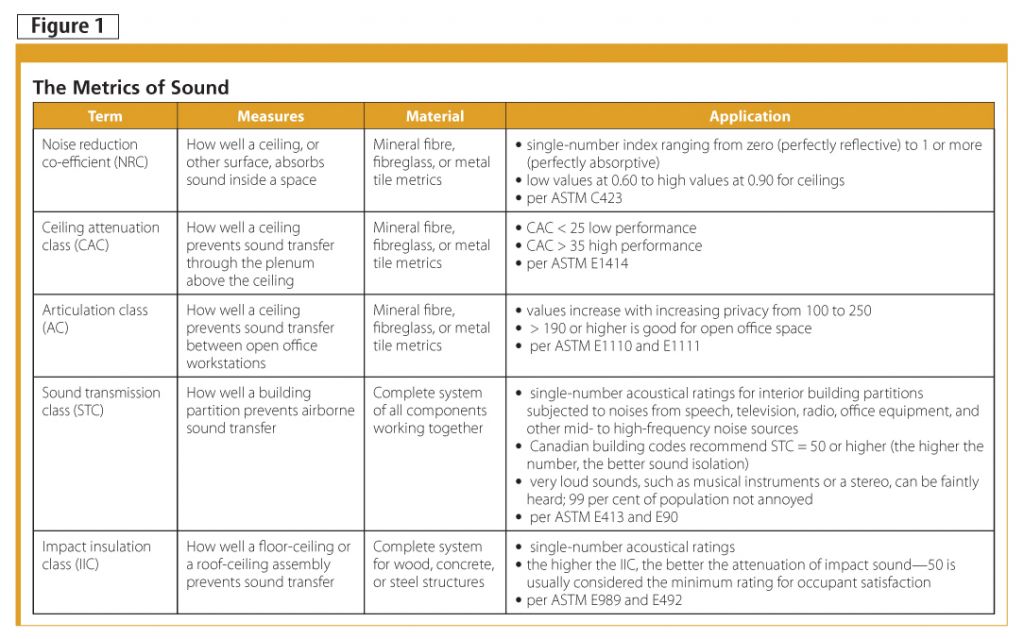

Acoustical metal ceiling panels provide sound absorption and reflection, while standard acoustical tiles typically provide only the former. Specific acoustic metrics are used to characterize the ceiling system’s acoustic effectiveness:

- noise reduction co-efficient (NRC);

- articulation class (AC); and

- ceiling attenuation class (CAC).

NRC and AC both indicate the ceiling’s ability to absorb sound inside a space and are fairly well correlated—if one increases, so does the other. The main difference is NRC is a better indicator of the ability of a ceiling (or other surface) to reduce the overall reverberation of noise as it reflects inside spaces or down corridors throughout time. AC is a better indicator of how human speech is attenuated in an open-plan layout for privacy and confidentiality.

If the general concern is overall noise and reverberation reduction, then the correct metric to specify is NRC. Values range from 0.0 (i.e. highly reflective) to more than 1.0 (i.e. very absorptive). NRC values of 0.60 or less are considered ‘low,’ whereas 0.65 to 0.85 is considered ‘moderate,’ and above 0.90 is ‘high.’ NRC is important in high noise areas where concentration, relaxation, and communication are needed.

Common backers on metal panels are made of cellulose, fibreglass, and other fibres. For enhanced acoustical performance, pads are usually 0.454 to 0.68-kg (1.0 to 1.5-pcf) density fibreglass insulation squares wrapped in a poly-sealed envelope. Typically, NRC for a metal ceiling panel with perforation and backer averages 0.70. When an acoustical pad is added, it increases to 0.90. This matches NRC values of higher-end mineral or fibreglass tiles. Perforation patterns in metal ceiling panels can vary from small to large open areas.

If the general concern is privacy and confidentiality between areas in close proximity that are not separated by enclosed isolating construction, the correct metric to specify is AC. Values range from around 120 (i.e. high reflectivity, low confidentiality) to more than 230 (i.e. high attenuation, high confidentiality). AC values of 160 or less are considered ‘low,’ from 170 to 180 is ‘moderate,’ and 190 and above are ‘high.’ AC values represent how well a ceiling system prevents human speech reflection over or around a barrier. For example, it is important in open office areas where individual workstations are separated by cubicle dividers or low walls, where concentration is critical.

The next type of metric, CAC, is not a measure of noise absorption/attenuation, but rather a measure of a ceiling’s ability to block the transmission of noise from an adjacent space via the common plenum above. Noise in the plenum may originate from flanking sources (demising walls that do not extend all the way up to the underside of the deck above; impact noise on the slab/roof above, etc.), which should be considered.

More often, CAC is the acoustical performance metric least taken into account. Since moderate to high CAC panels typically have significantly lower sound absorption qualities (i.e. NRC and AC), choosing CAC over the other metrics may mean sacrificing acoustic comfort, privacy, confidentiality, and intelligibility for isolation from noise that does not exist in the plenum.

Beyond absorbing noise for the sake of comfort, privacy, and confidentiality, another acoustic performance goal is accurate, intelligible, speech communication. In meeting or conference rooms, procedure rooms requiring team communication, worship centres, music therapy spaces, group education rooms, and geriatric care areas, the ceiling’s role is not one of absorption, but instead of passive reinforcement of the spoken word. Loud reflections off the ceiling help listeners hear and understand what is being said. It helps them feel closer to, and more intimate with, the people speaking. It helps them concentrate and remember. There are several common acoustic performance metrics to consider. Figure 1 summarizes criteria and applications.

Esthetic considerations

Esthetic considerations

Beyond acoustic performance, metal ceiling systems esthetics—size, shape, pattern, and finish—are extremely important. For example, in the lobby of a senior residence, the metal ceiling can become an extension of selected interior finishes. The ceiling system conceals wiring and equipment, while incorporating lighting fixtures, security cameras, audio/visual components, and HVAC structures. While the residences and visitors see a clean, stylish ceiling, the maintenance team appreciates the practicality of a system that is easily accessible to repair and replace the infrastructure above the panels.

Further contributing to and extending a ceiling’s esthetic, metal panels may be finished in a full spectrum of colours and a breadth of techniques. The most common finish for metal ceilings is polyester enamel—applied as a pre-painted system to a metal coil or post-painted as a dry powder to a previously formed metal panel. Each finish provides similar sustainability and durability performance characteristics, but there are also differences.

Pre-painted finish

The pre-painted finish is the process of painting a metal coil before forming; it contains more steps in the factory-controlled application process when compared to the post-paint method. This application involves a flat metal strip (coil of metal) that is unwound. Both the top and bottom sides are cleaned, pre-treated for improved adhesion and enhanced corrosion resistance, primed, oven-cured, top-coated with the desired colour, and oven-cured again—all in a continuous process. Benefits of the pre-painted process consist of lower gloss levels, tighter tolerance in colour, superior paint adhesion, and high flexibility for forming after painting.

Post-painted powder finish

Post-painted powder finish is applied after forming a metal panel and involves the application of dry powder paint through an electrostatic spray gun. The finish then cures to its final hardness. While a powder coat finish may provide a somewhat harder finish (per ASTM D3363, Standard Test Method for Film Hardness by Pencil Test), there are some disadvantages, such as the possibility of uneven colour coverage, making touchup of scratches more difficult and reduced impact-resistance.

In North America, the most commonly specified paint finish application on grid suspension and metal panel ceiling systems is the pre-painted method. This process accounts for more than 90 percent of the coatings used for commercial metal ceilings due to its lower cost, durability, colour consistency, and paint adhesion. Paint flexibility and adhesion are the keys to the superior impact-resistance per ASTM D2794, Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact).

Standards and performance

Canadian and provincial building codes list many standards to guide fire resistance, seismic requirements, luminous reflectance, and other parameters for ceiling systems.

Material selections

The following pertain to suspension, tiles, and coatings:

- ASTM B209, Standard Specifications for Aluminum and Aluminum-alloy Sheets and Plates;

- ASTM C367, Standard Test Methods for Strength Properties of Prefabricated Architectural Acoustical Tiles or Lay-in Ceiling Panels;

- ASTM E1264, Standard Classification for Acoustical Ceiling Products;

- ASTM D3363; and

- ASTM D2794.

Fire and safety

These standards overlap and complement one another:

- Underwriters Laboratories (UL) 723, Test for Surface Burning Characteristics of Building Materials, connected to UL 263, Fire Tests of Building Construction and Materials;

- UL 580, Tests for Uplift Resistance of Roof Assemblies for Exterior Installations or with Wind Load Requirements;

- ASTM E119, Standard Test Method for Fire Tests of Building Construction and Materials;

- Underwriters Laboratories of Canada (CAN/ULC) S102, Standard for Method of Test for Surface Burning Characteristics of Building Materials and Assemblies; and

- CAN/ULC-S101, Standard Methods of Fire Endurance Tests of Building Construction and Materials.

Installation and seismic

The following standards involve seismic considerations in ceiling installation:

- ASTM C635;

- ASTM C636; and

- Canadian Standards Association (CAN/CSA) S832-06 (R2011), Seismic Risk Reduction of Operational and Functional Components of Buildings.

Luminous reflectance

Applicable to both mineral and metal panels, luminous reflectance is guided by ASTM E1477, Standard Test Method for Luminous Reflectance Factor of Acoustical Materials by Use of Integrating-sphere Reflectometers.

Acoustical testing standards

These standards are critical with regard to acoustical testing:

- ASTM E1111, Standard Test Methods for Measuring the Inter-zone Attenuation of Open-office Components (i.e. AC);

- ASTM E1110, Classification for Determination of Articulation Class;

- ASTM E1414, Standard Test Methods for Airborne Sound Attenuation Between Rooms Sharing a Common Ceiling Plenum (i.e. CAC);

- ASTM E413-04, Classification for Rating Sound Insulation (i.e. CAC); and

- ASTM C423, Standard Test Methods for Sound Absorption and Sound Absorption Co-efficients by the Reverberation Room Method (i.e. NRC).

Conclusion

Influenced by multiple standards, code requirements, and project-specific considerations, a ceiling system’s acoustic success combines careful material selection, a balanced approach, expert installation, and dedicated teamwork between manufacturing companies, architects, acoustical engineers, and specifiers.

Isabelle Champagne, CTR, is Chicago Metallic Corporation’s district manager for Ontario and Québec. Born in Montréal, she draws from 25 years of experience in the construction industry with a focus on the building envelope, acoustic performance, and ceiling systems. Throughout her career, she has served as an active member and volunteer with CSC. She may be reached at ichampagne@chicagometallic.com.

Isabelle Champagne, CTR, is Chicago Metallic Corporation’s district manager for Ontario and Québec. Born in Montréal, she draws from 25 years of experience in the construction industry with a focus on the building envelope, acoustic performance, and ceiling systems. Throughout her career, she has served as an active member and volunteer with CSC. She may be reached at ichampagne@chicagometallic.com.