Achieving Energy-efficient Buildings: Using thermally enhanced channel glass for energy savings

By James Donoghue, MBA

In this age of energy conservation, architects and designers must consider the benefits of natural light admitted through fenestration products versus light from electrical systems. With the balance usually swinging toward natural light, it is all about managing the impact on a building’s thermal performance. The main challenge of fenestration assemblies is allowing natural light into the building and effectively distributing it throughout interior spaces.

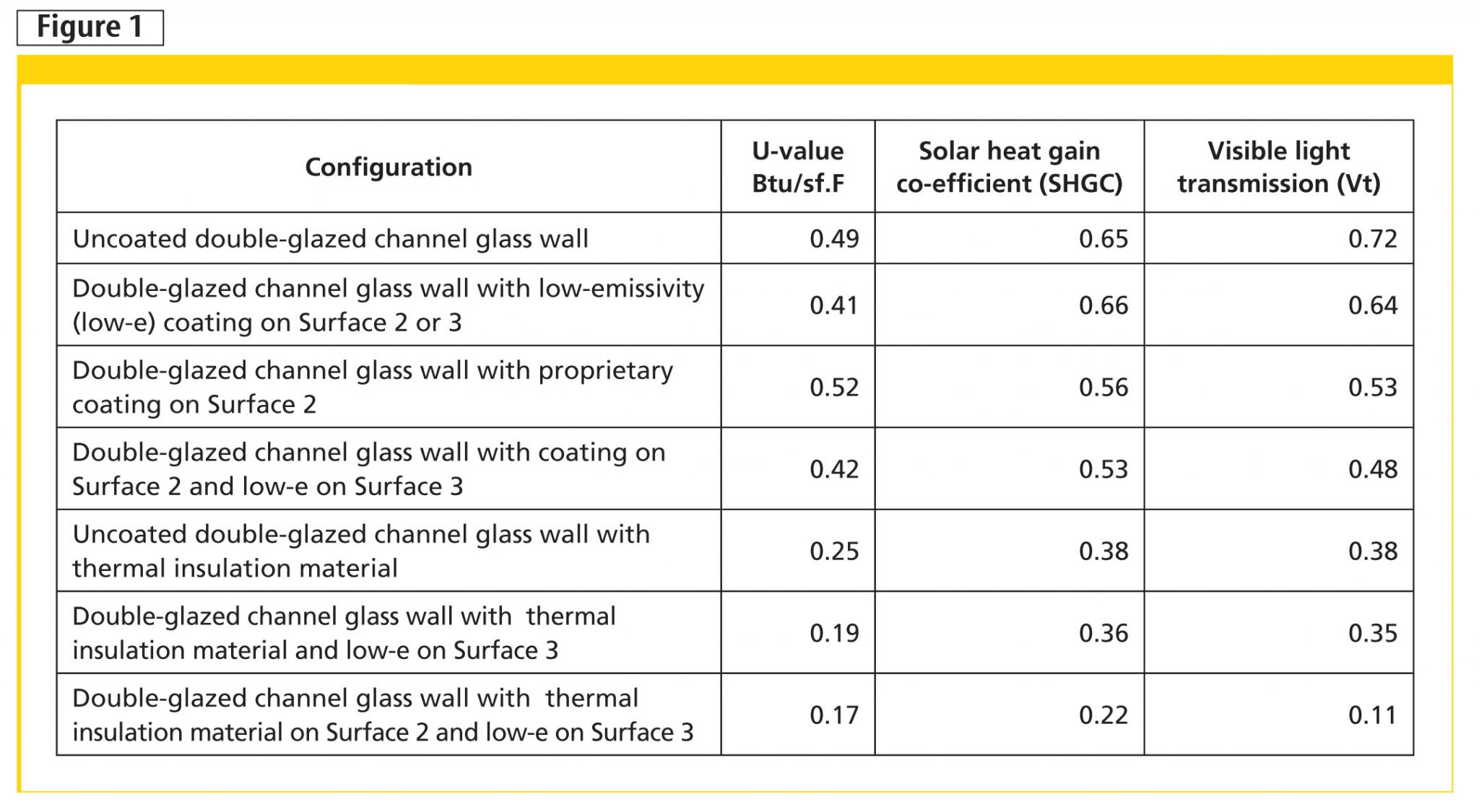

The difficulty with natural lighting is the portal through which it comes (e.g. window, skylight, or curtain wall) is also a weak point in the exterior thermal envelope. The ability of glass areas to retard heat loss or gain is a primary consideration and plays a vital role in controlling utility costs. The growing emphasis on energy conservation has resulted in the increased use of low-emissivity (low-e) coatings, solar heat gain co-efficient (SHGC) reduction coatings, and the inclusion of translucent insulation materials between the layers of glass to address this requirement.

Channel glass, a U-shaped, rolled cast glass manufactured with surface textures imprinted on the exterior face, has the ability to create large areas of glass with minimal exposed framing elements. Each texture delivers a unique pattern of diffusion and reflection. The textured surfaces allow the creation of a ‘sparkling’ wall in daylight and a ‘glowing’ wall when lit from within at night. The glass is available in a standard pale green cast or in an almost-clear, low-iron form. Some of these textures can be thermally coated for greater performance or sandblast-finished for a diffused, frosted appearance. Permanent, fired-in enamel frit coatings in hundreds of vivid colours are also available.

In this article, the thermal performance of channel glass walls will be explained and discussed with respect to the materials’ insulating capacity and key thermal properties. The glass’ relationship with framing systems and overall esthetic possibilities will also be examined.

Insulating capabilities of channel glass

Glass is a silica product and, as such, does not have a high insulating capability, regardless of thickness. Most glass curtain walls contain insulated glass (IG) units composed of two glass layers approximately 6 mm (0.24 in.) thick, separated by an air space. In other words, 12 mm (1/2-in.) of glass product separates the interior from the exterior of a building’s façade. Urethane foam has an insulating capability typically five times more efficient than glass—a 24-mm (1-in.) thick urethane foam insulation provides a U-value of 0.23 W/m3K. However, even if glass had the same insulating factor, it would not amount to much of a thermal barrier. Most thermal resistance found in a translucent glass curtain wall is provided by the gas trapped between the interior and exterior layers of the double-glazed system or the IG units.

Heat transfer through a glass wall comes from two primary sources: difference in ambient air temperature between the building’s interior and exterior, and solar radiation. The first source of heat transfer—ambient air temperature differential—is in addition to effects caused by air leakage; a temperature differential at an exterior wall (e.g. cold exterior, warm interior) results in the transfer of heat energy by conduction and convection through the glass barrier.

The second source of energy transfer through glass is from solar radiation—the passage of heat as energy through the glass. Solar radiation striking the glass surface is reflected, absorbed, or transmitted through the glass to the interior. Radiant heat loss or gain can be managed by placing coatings on the glass that reflect heat energy while admitting visible light.

The methods used to control energy flow (i.e. coatings or translucent insulation materials) usually have an effect on the amount of visible light transmitted to the interior. Coatings and insulation materials can block heat but also reduce visible transmission. Therefore, a careful balance between limiting heat transmission and allowing visible light through is required. Transparency is limited, but a varied amount of translucency is achievable while providing privacy.