Achieving advanced thermal performance in steel structures

Wall assemblies

Reducing the amount of energy required to heat or cool a facility requires that one lower the amount of heat transferred through the building envelope. Therefore, selecting the proper exterior wall system is critical. Thermal performance of steel wall systems can vary greatly, and there are solutions available to meet stringent Canadian building codes.

Blanket insulation options

There are two common wall insulation approaches to employing systems construction. The first is a combination of fibreglass blanket insulation and thermal spacer blocks. The blanket insulation is installed from the eave strut to the base of the wall, and thermal spacer blocks are used along the girts to counteract blanket insulation compression at those points.

Using discrete thermal spacer blocks is an advantage. The discrete thermal spacer blocks are located at the attachment of the metal wall pane to the girts. This reduces the thermal bridging at the fasteners. The thermal spacer blocks also space the metal wall panel away from the girts. This allows the blanket insulation to be less compressed at the girts and promotes a fuller recovery of the depth of the insulation between the girts. This option can be used in some of the climate zones in Canada. It depends on the type of metal wall panel (and its profile), along with the insulation thickness.

Insulated metal panels

The second approach uses a factory-insulated wall panel system. With insulated metal panels (IMPs), a light-gauge metal skin covers both sides of a foam core insulation of various thicknesses. Typically, manufacturers offer IMPs with up to 100 mm (4 in.) of insulation in the panel.

Beyond thermal performance, a major advantage of this approach is one-step installation. An IMP completely sidesteps the need to install additional liners. Further, it creates a durable and visually pleasing interior wall surface. In many cases, the stiffness of the panel will also allow for increased girt spacing.

Minimizing air leakage

Additionally, air leakage into and out of the building is a critical factor in its thermal performance, and can be an important consideration when selecting a building approach. The air barrier must be properly designed, detailed, and installed. Experience shows this can be achieved with a systems solutions approach.

Attention to the design, detail, and installation of the air barrier of a systems solution building makes it possible to meet the air leakage requirements of the energy code. Many manufacturers have tested their roof and wall systems for air leakage. Metal Building Manufacturers Association (MBMA) also has tested generic wall systems for air leakage. These tests have shown roof and wall assemblies can be used as an integral part of the building’s air

barrier system.

The facings of many blanket fibreglass insulations will meet the requirements of the air barrier. Sealing the side-laps to make the air barrier continuous is a common approach. IMPs can also be a component of an air barrier system.

Roof assemblies

It is no secret that the roof will be a critical component when determining a structure’s thermal performance. Similar to wall panels, there is a wide range of efficiencies in terms of metal roof panel performance, including options that meet appropriate Canadian energy codes. At a minimum, it is important to identify an option that can accommodate additional insulation thicknesses.

Insulation systems with liner panels

One such approach is an insulation system that uses a liner panel atop roof purlins. Taking this particular approach,

either rigid board insulation or as much as 330 mm (13 in.) of uncompressed blanket insulation is placed between the exterior roof panels and a steel liner panel.

Determining thermal performance of assemblies using fibreglass insulation has been done through guarded hot-box testing and thermal 3D finite element analysis. Depending on the depth of the assembly and the type of exterior roof panel, the U-value of the assembly can be between 0.052 and 0.026.

Additionally, having the liner panel located atop the purlins provides access to them for suspended lighting and HVAC ducts. In some cases, the liner panel can act as the roof diaphragm, eliminating the need for roof bracing.

New insulation technology

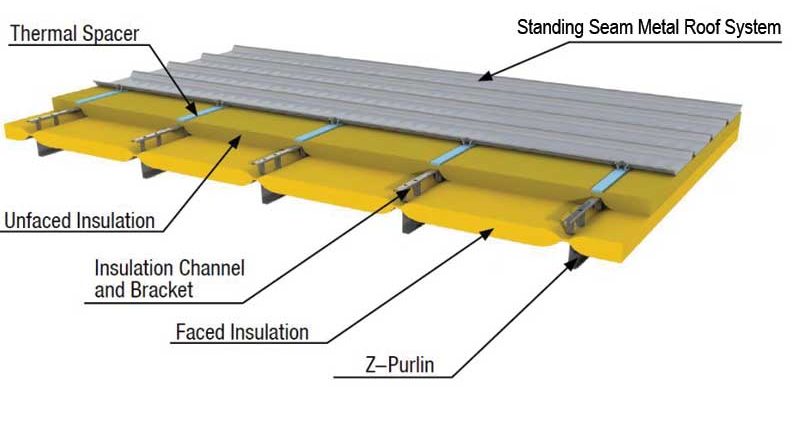

There is insulation technology new to North America that helps minimize insulation compression without the use of a liner panel in order to maximize thermal performance. These systems will employ structural brackets and continuous support channels to raise standing-seam metal roof panel systems 150 mm (6 in.) or more above the top of the roof purlins. This provides space above the purlins so the fibreglass blanket insulation retains much of its depth and insulating capacity. This approach increases the efficiency of the insulation, whereas other over-the-purlin options can significantly compress the insulation at the purlins, thereby limiting its effectiveness.

Other considerations

As roofing insulation systems become more sophisticated, it is even more important to opt for a high-quality roof proven not to leak. If insulation systems, such as those with a liner panel, limit access to the structural framing system, it can be difficult to diagnose and repair a leak. Another consideration when selecting roof options for thermal performance is the roof’s lifespan. The more sophisticated the insulation approach, the bigger (and likely costlier) the challenge to replace the roof. Galvalume standing-seam metal roof systems are a strong option, offering a proven lifespan of 40 years, with many lasting far longer.

Realizing the benefits

No matter the facility, systems construction can prove to be a valuable option to meet the heightened demands for energy efficiency from regulators and occupants. New and evolving technology is making this approach more efficient than ever, with a variety of roof and wall systems that marry thermal performance with design flexibility.

The key to achieving an efficient steel structure starts with knowing its exact code requirements and calculating its U-value. Then, it becomes about selecting quality and long-lasting materials to help mitigate structural issues that may be exacerbated because of insulation systems.

Rich Grabmeier, RRC, LEED AP, is a business development manager focusing on innovation with Butler Manufacturing. He has more than 30 years of experience in the building industry, with a focus on product and process trends and improvements. Grabmeier graduated from the University of Texas at Austin with a bachelor’s degree in architectural engineering. He can be reached at editorial@butlermfg.com.

Rich Grabmeier, RRC, LEED AP, is a business development manager focusing on innovation with Butler Manufacturing. He has more than 30 years of experience in the building industry, with a focus on product and process trends and improvements. Grabmeier graduated from the University of Texas at Austin with a bachelor’s degree in architectural engineering. He can be reached at editorial@butlermfg.com.

Mark Henry, PE, is a senior research engineer with Butler Manufacturing. He has a bachelor’s science degree in architectural engineering from the University of Kansas. Henry has 27 years of industry experience. He can be reached at editorial@butlermfg.com.

Mark Henry, PE, is a senior research engineer with Butler Manufacturing. He has a bachelor’s science degree in architectural engineering from the University of Kansas. Henry has 27 years of industry experience. He can be reached at editorial@butlermfg.com.