The pipe rehabilitation process

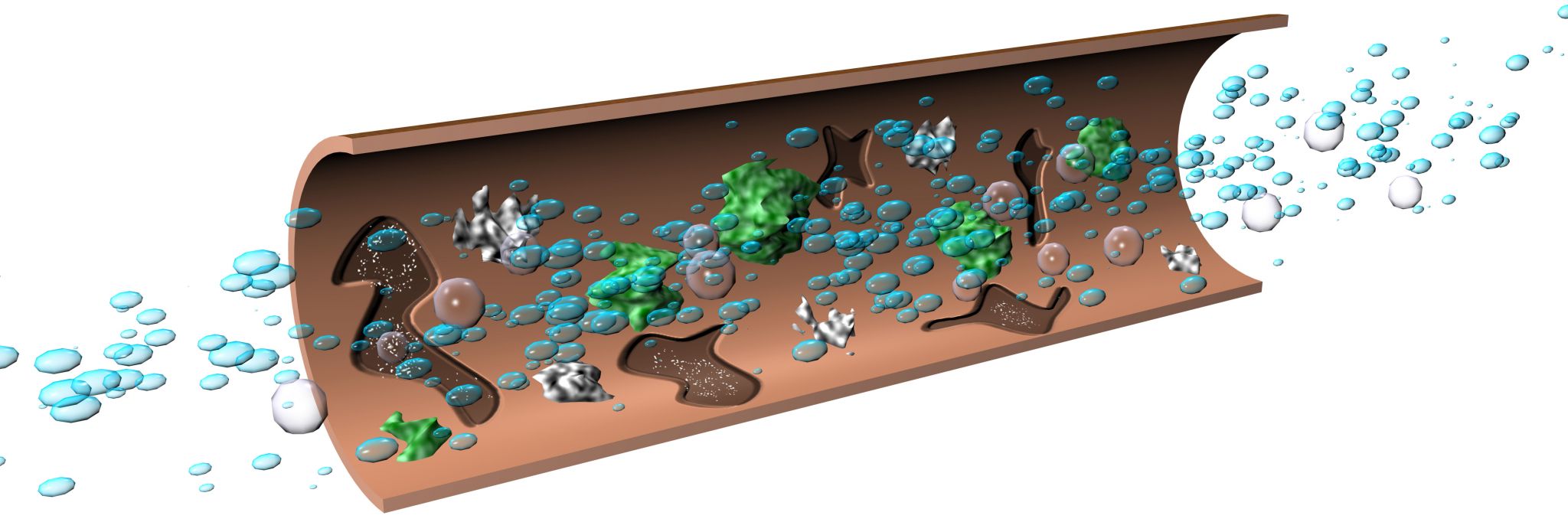

Step 1: Pipe System Diagnosis

The internal pipe system is mapped, and a plan is implemented for work completion. The piping system is inspected for integrity. After testing for leaks, the pipes are prepared for cleaning.

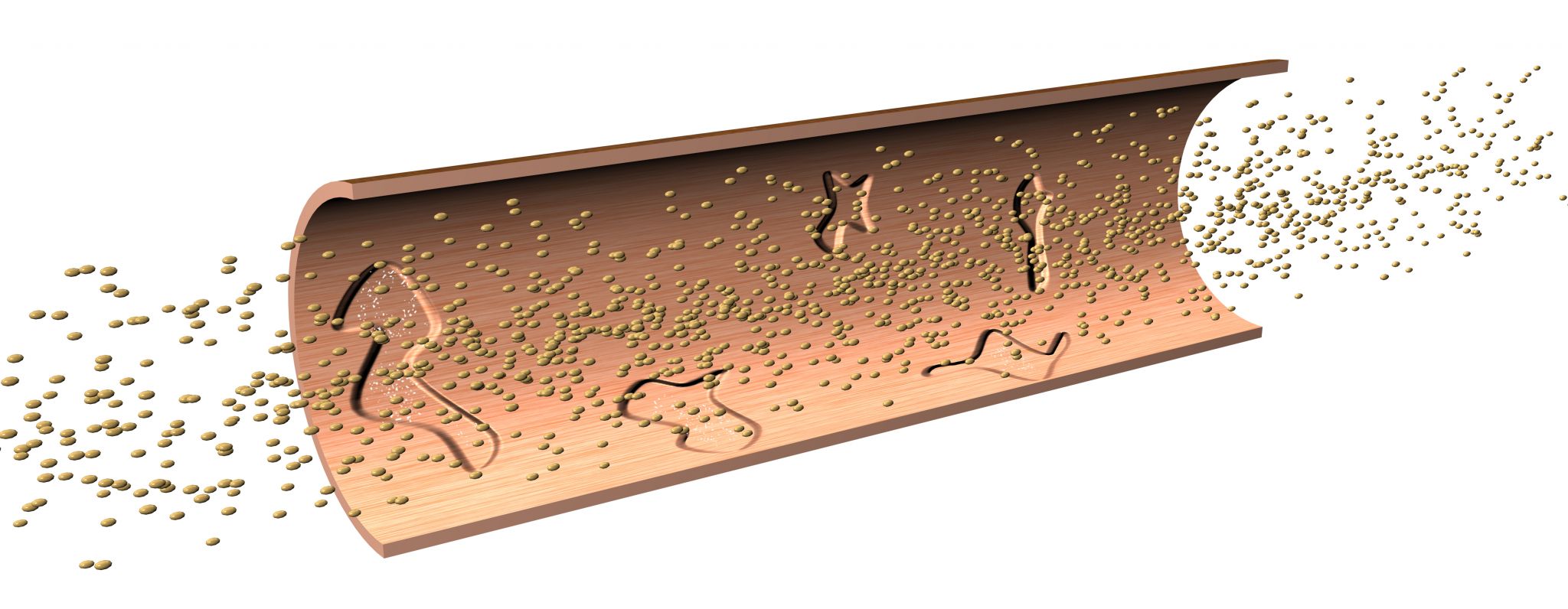

Step 2: Pipe Cleaning

Pipes are dried with heated, compressed air. A safe abrading agent is blown through the pipe system, removing rust and corrosion by-products collected in a holding unit for disposal. Compressed air is applied once again to remove fine particles.

Step 3: Epoxy Lining

Optimal internal pipe surface temperature is created before applying the epoxy coating. Another air pressure leak test is performed. Conditioned air is introduced into the pipe to uniformly distribute the epoxy coating throughout the pipe segment. Following the coating application, continuous controlled air flows through the piping to facilitate epoxy curing.

Step 4: System Reassembly and Final Inspection

After the epoxy coating cures, valves and couplings are refitted. A final leak test and inspection confirms lining integrity. Water quality, volume, and flow tests confirm system functionality.

To read the full article, click here.