Concrete Floors: Does ‘sealed’ mean the same thing as ‘polished?’

By Andy Bowman

The continued rise in popularity of polished concrete floors, combined with a spate of new ‘polishing’ products on the market, has created a perfect storm for construction specifiers. The industry has responded by releasing a new standard to measure and evaluate polished concrete surfaces.

Polished concrete has become a popular flooring choice in contemporary design. It is economical and durable, which has made it a good fit for warehouse and retail applications. However, economy alone cannot account for the material’s popularity. Polished concrete’s allure stems from the fact it is an artisanal product—rustic, yet at the same time refined. The combination of earthy material with industrial esthetic has caused polished concrete floors to show up everywhere from upscale commercial environments to residential design.

The rapid increase in polished concrete installations has made it difficult for scientific methods and standards to keep pace. Today’s concrete polishing industry uses a wide range of systems and equipment, along with various specially formulated chemicals and abrasives. This means the specification of a polished floor can result in myriad actual finished surfaces.

Problems and solutions

In particular, many coatings are now being marketed to accomplish the sealing of concrete floors. What has become obscured is the fact that, in traditional polishing operations, it is the concrete itself that creates the characteristic glossiness and shine. A polished concrete surface is, strictly speaking, one in which abrasive tools with progressively finer grit have been used to refine the concrete material. While small scale pits or imperfections refract light, highly polished concrete will reflect the light. Ideally, polished concrete would be scratch-free and have a surface texture without abrasion points—in other words, it would not rely on a sealant to produce its gloss.

Historically, only one tool has been used to provide a quantitative standard for finished concrete surfaces: the gloss meter. While a gloss meter records the light reflected from a surface, it does not measure the actual surface texture. The use of a gloss meter alone to assess a surface can mask its imperfections by measuring the reflection produced by topical concrete polishing sealers actually covering flaws and scratches.

With sustainability and lifecycle issues coming increasingly to the fore, the polishing industry would benefit from de-emphasizing the mere appearance of glossiness and taking a more holistic approach. Accomplishing this involves a shift in focus toward standards that are performance-based and encourage use of a good concrete mix in the initial pour. Gloss will then become a natural byproduct of the polishing operation.

The concrete finishing process is ideally a multidisciplinary activity resulting in tailored properties that improve not only the surface’s appearance, but also its function and serviceability. Delivering a high-quality concrete surface will reduce the maintenance costs currently borne by end users who are spending much more than expected on maintenance to keep their floors looking as good as they did the day they were finished.

Defining a more specific process

Concrete surface refinement involves a series of progressive steps that eliminate scratches and unevenness. Various finishing techniques and tools can result in a high-quality end result. It makes sense, therefore, not to prescribe a narrow range of accepted procedures, but to instead adopt a measurement standard that sets a high bar for surface measurement and establishes specific objectives for small-scale refinement qualities.

Last fall, the Concrete Sawing and Drilling Association (CSDA)—an association representing North American contractors in the concrete sawing and drilling and related industries—adopted a new standard, known as Measuring Concrete Micro Surface Texture (ST115). The association says the document was produced in response to concerns on the part of architects and engineers regarding quality issues with polished concrete.

The standard has two main components. It identifies approved instrumentation for measuring surface texture, and provides a benchmark measurement procedure for contractors and specifiers to follow. The standard also includes directions for documenting the texture readings and contains a resource section with relevant code information and glossary terms.

The standard has two main components. It identifies approved instrumentation for measuring surface texture, and provides a benchmark measurement procedure for contractors and specifiers to follow. The standard also includes directions for documenting the texture readings and contains a resource section with relevant code information and glossary terms.

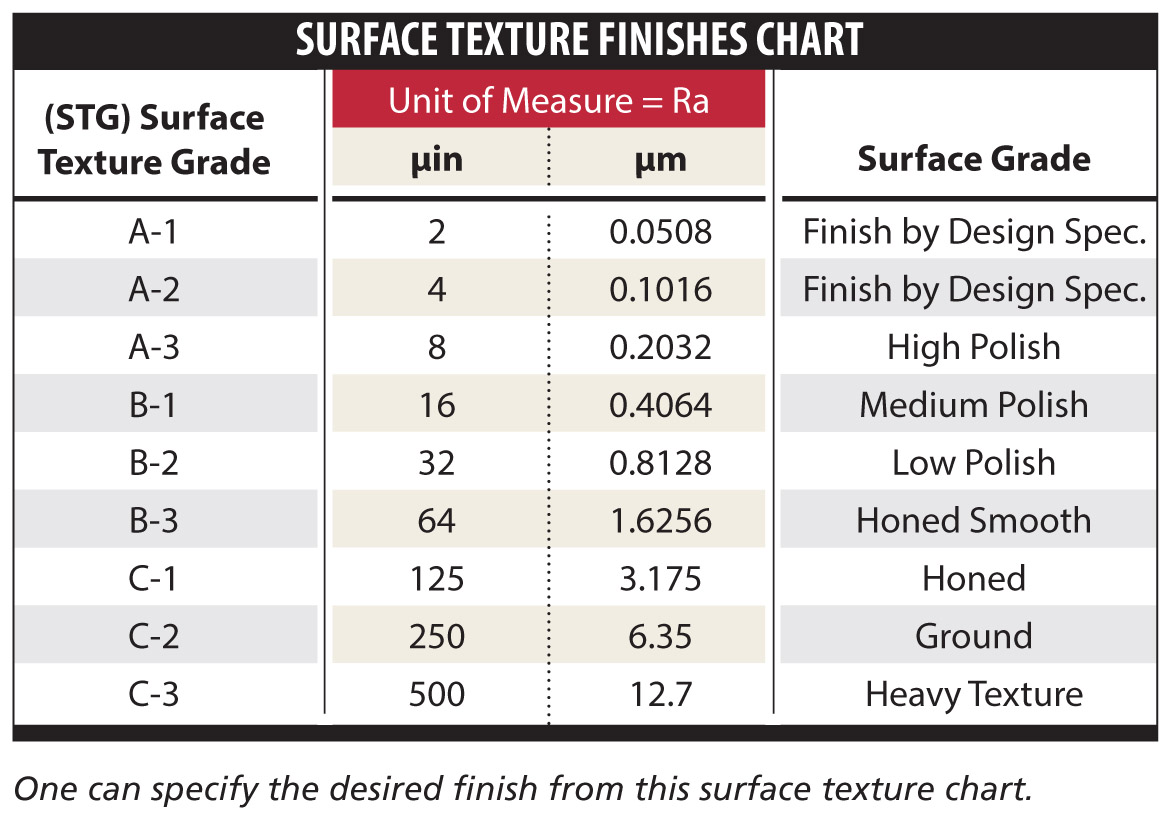

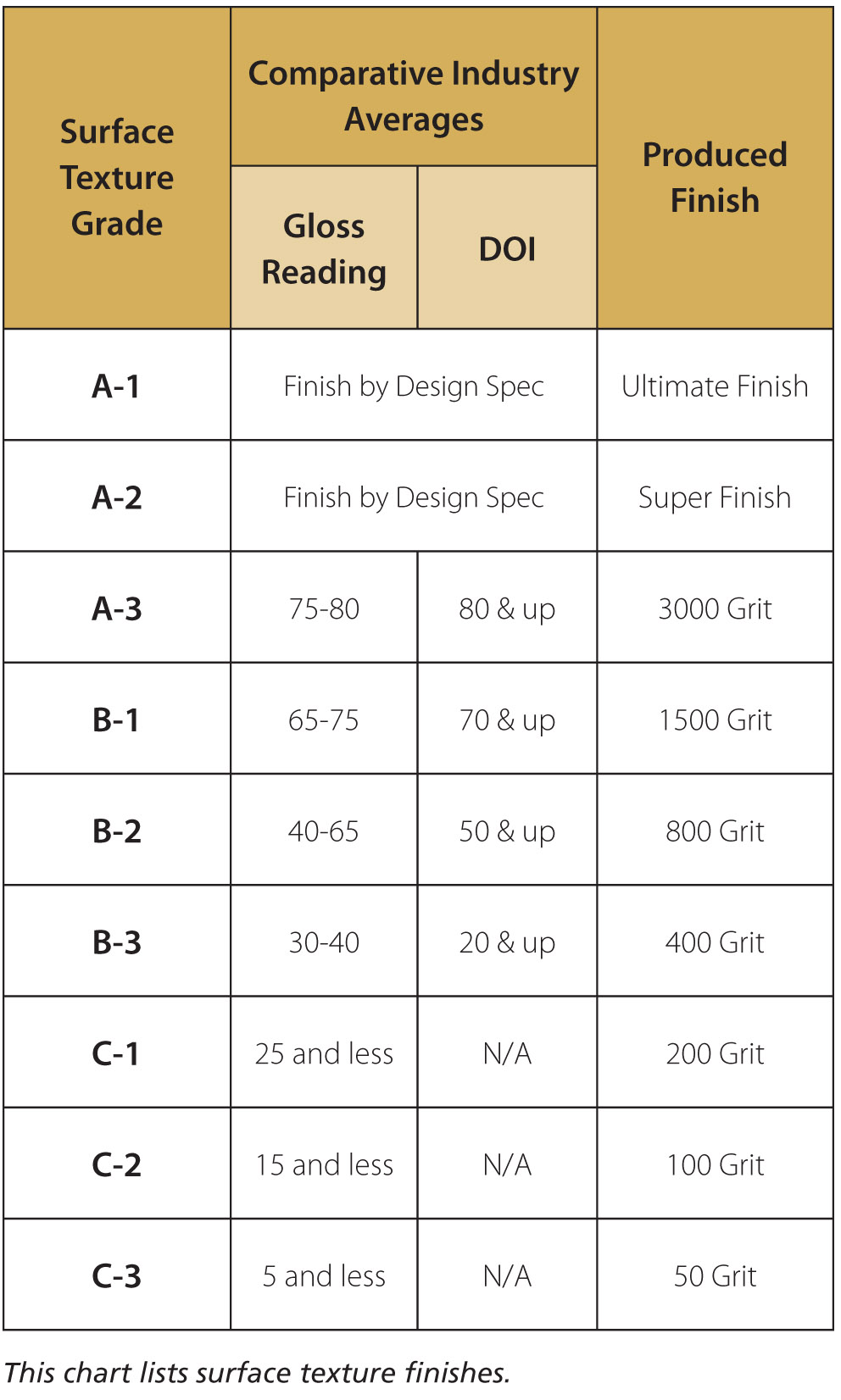

CSDA ST115 is the concrete industry’s first standard for quantifying a concrete surface by accurately reading its texture and assigning the proper designation code or surface texture grade (STG). It allows the design community and end-users to have a more structured conversation about the quality and sustainability of a polished concrete surface.

To create the standard, representatives came together from five major industry associations across five continents: CSDA, American Concrete Institute (ACI), ASTM International, American Society of Mechanical Engineers (ASME), and International Concrete Repair Institute (ICRI). Committee members were experts in the fields of surface metrology (the study of surface geometry), concrete finishing, concrete repair, and concrete mix designs. They considered a wide array of information on surface measurement techniques and surface parameters in practical use.

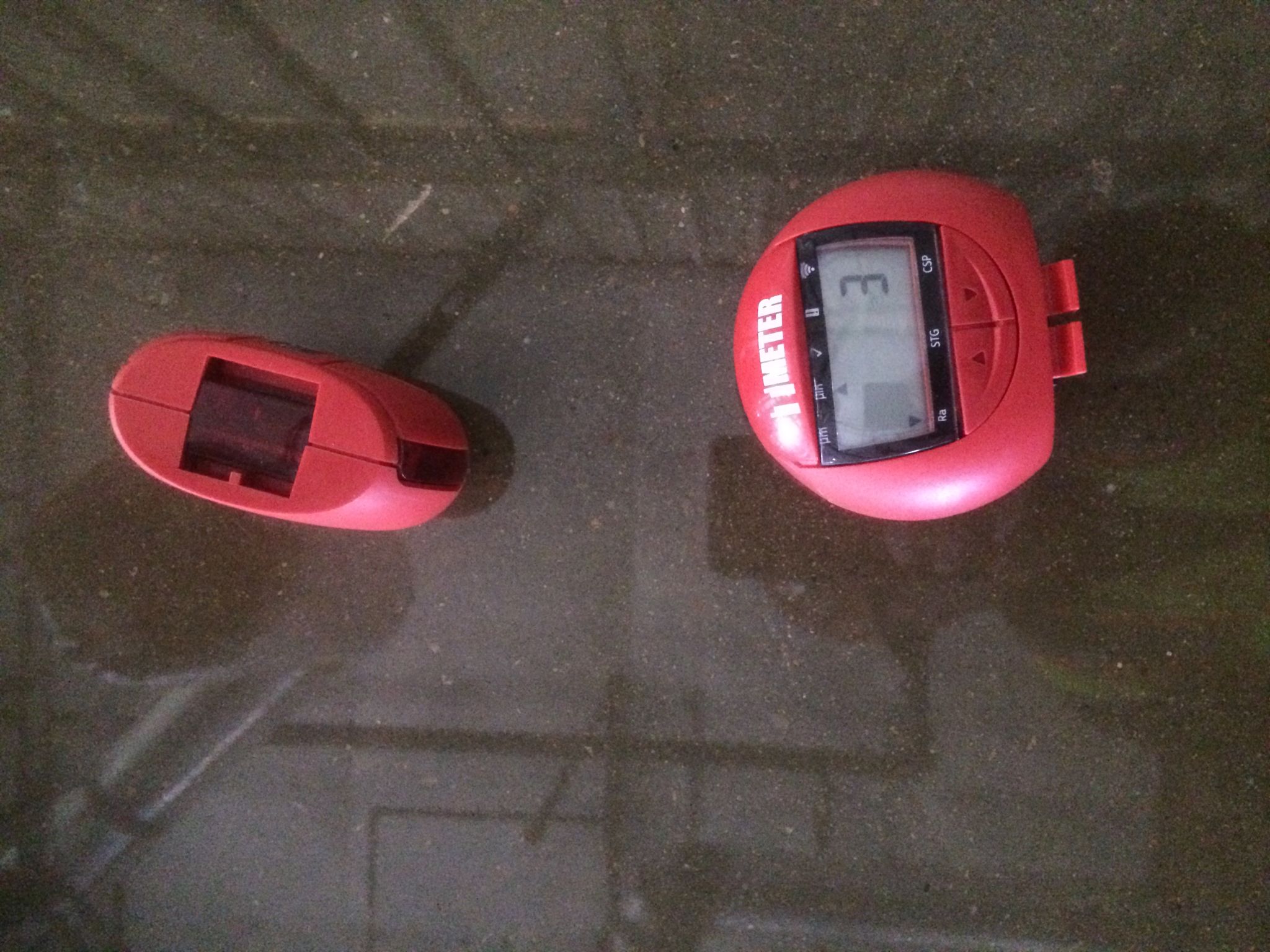

While ST115 is the first standard of its kind for the concrete industry, there are equivalent standards in other industries. The metal and plastic finishing industries, for example, both adopted similar standards more than 50 years ago because they had experienced the same challenges with interpretation and processing techniques. Further, the standard promotes using profilometers to measure surface roughness; these instruments have been used in the wider concrete industry for years. Profilometers meet the standard’s specific requirement for using “contact, skidded instruments.” (A skid is a metal rest attached to the probe on a profilometer; it moves in conjunction with the stylus). It is the use of these devices that enable the assignment of a texture grading code to the concrete finish.

Taking a closer look

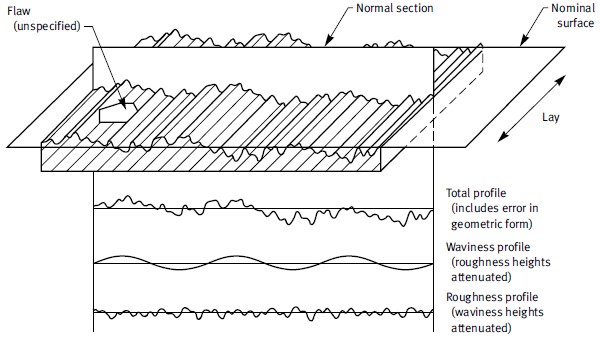

CSDA ST115 is concerned specifically with numerically quantifying the geometric irregularities of a concrete surface—that is, its finely spaced irregularities. It is not intended to address waviness, which is defined as the more widely spaced component of surface texture. Since profilometers measure both roughness and waviness, filters have been defined within the standard. These filters provide long- and short-wavelength cutoff values eliminating data that do not significantly contribute to the roughness measurement.

Collecting this finely tuned range of data is possible because of the sensitivity of modern surface texture measuring profilometers. Their electronic recording systems capture minor fluctuations of stylus movement over the concrete’s evaluation length. ‘Ra,’ or average roughness, is the parameter used as the basis for CSDA ST115. The intent of the measurement method is to examine the ways in which finishing processes influence surface textures and how the surface texture, in turn, influences gloss, friction and sustainability. The recommended profilometers can be used in conjunction with gloss meters and distinctness-of-image (DOI) meters.

The CSDA standard applies to any surface that has been produced by processes of abrading, cutting, grinding, milling, honing, or polishing. It allows for the possibility of encountering high amounts of flaw, roll out, or voids and provides solutions for how to properly accommodate these flaws and get a reliable reading. The quantitative surface refinement number does not vary depending on the type of polish guard or sealer used.

Test results meeting the standard indicate whether steps in the polishing process have been skipped or are incomplete; they also enable the processor of a polished floor system to monitor the refinement capability of a specific tool in a multiple tooling system by measuring the surface of the concrete after each individual tool used. By knowing the quality of abrasives currently being used, a processer can then make an informed comparison to similar abrasives made by competitive manufacturers. He or she can keep track of each step’s finish grade and potentially assemble the best tool selection procedure for his or her particular equipment or process.

Test results meeting the standard indicate whether steps in the polishing process have been skipped or are incomplete; they also enable the processor of a polished floor system to monitor the refinement capability of a specific tool in a multiple tooling system by measuring the surface of the concrete after each individual tool used. By knowing the quality of abrasives currently being used, a processer can then make an informed comparison to similar abrasives made by competitive manufacturers. He or she can keep track of each step’s finish grade and potentially assemble the best tool selection procedure for his or her particular equipment or process.

Conclusion

CSDA ST115 is just the first step in moving the industry toward more systematic and responsible polishing practices. The standards committee assembled by the CSDA also developed a companion document, a best practices guide known as CSDA BP015, Green Polishing and Grinding Practices. This guide helps concrete polishing and grinding contractors perform their work in a more environmentally responsible manner. Its recommendations cover work performed from office to jobsite. Additionally, a standard based on CSDA ST115 is likely to be adopted by ASTM International. A draft of that document is currently in subcommittee review.

Implementing ST115 will result in a detailed map of a concrete surface, giving contractors, designers, and owners a more complete understanding of their finished product. Once a surface meets the requirements outlined in ST115, it will automatically produce a high gloss, since gloss is a byproduct of surface refinement. The result will be improved operations and maintenance workflows, reduced costs, environmental benefits, and a better material in service for end users.

Andy Bowman is a surface metrology specialist and principal of Adaptive Concrete Innovations LLC. He has chaired a committee comprising 16 experts in the fields of surface metrology, concrete finishing, concrete repair, and concrete mix designs. This committee, which authored ST115, represented five major industry associations and five continents. Bowman can be reached at bb@aciconcrete.net.

Andy Bowman is a surface metrology specialist and principal of Adaptive Concrete Innovations LLC. He has chaired a committee comprising 16 experts in the fields of surface metrology, concrete finishing, concrete repair, and concrete mix designs. This committee, which authored ST115, represented five major industry associations and five continents. Bowman can be reached at bb@aciconcrete.net.

To read “Concrete Floors: Understanding the Terminology,” click here.