One Building’s Scrap is Another Building’s Stone: Recycling and refurbishing Tyndall stone

By Chris Ambrozic and Mark D. Hagel, PhD, P.Eng.

One of the best ways to be environmentally conscious during construction is to re-employ components from other buildings reaching the end of their design life or being renovated for new uses. Repurposing building material can have the additional benefit of acquiring Leadership in Energy and Environmental Design (LEED) credits for projects seeking certification.

The modular nature of masonry has easily lent itself to this form of recycling as far back as the reuse of marble from the Colosseum in Rome. After an earthquake in 1349 AD, the north end of the Colosseum collapsed. Following the earthquake, several churches and palaces were constructed using the reclaimed stone, the most notable being the use of 2522 cart-loads in the construction of portions of St. Peter’s Basilica in the 16th century.1 More recently, the historic brick masonry esthetic has been accomplished by cleaning and reusing masonry materials from buildings undergoing demolition or renovation.

Similarly, two projects in Edmonton employed recycled Tyndall stone cladding. This material is a cream-coloured dolomitic limestone quarried in Manitoba, typically containing coloured mottling and decorative fossils caused by the burrowing of marine creatures when the limestone was deposited. The stone was first used in the construction of Lower Fort Garry in 1832, and has since been used on notable Canadian projects including:

- Empress Hotel (Victoria, B.C.);

- Canadian Museum of Civilization (Hull, Que.); and

- Canadian Parliament Buildings (Ottawa).2

This article discusses the techniques employed to refurbish and resize this stone to match the existing stone on two projects, including use of one of the largest stone-saws in Western Canada. It reviews the shop drawings required to properly detail and shape the material to meet the cladding requirements, along with the engineering of the anchorage system to hang the stone panels.

The first project, the Innovation Centre of Engineering (ICE) at the University of Alberta (UAlberta), reused anchored Tyndall stone panels recovered during the renovation and demolition of the original Hudson’s Bay Company Department Store. The second project, the Government of Alberta Federal Building, clad its 11th floor addition with a selection of the 1000 Tyndall stone panels recovered from its own partial demolition.

Hudson’s Bay Building

Designated in 1989 as a Municipal Historic Resource, the Hudson’s Bay property is a valued landmark along Jasper Avenue in downtown Edmonton. The Tyndall stone and black granite commercial building occupies an entire block and is situated on the corner of Jasper and 102nd Street. Constructed in 1939, the original three-storey structure was designed in the Moderne style of architecture by Moody and Moore. The north addition was designed by Kelvin C. Stanley and Company Architects in 1955.3

The building is one of the few surviving examples of Moderne architecture in Edmonton. This style emerged in the late 1920s and remained popular until the 1940s; it typically produced asymmetrical buildings cubic in form, often with rounded corners where two walls would meet in a curve rather than squared. Other typical characteristics include flat roofs and untextured stucco walls.4

The Hudson’s Bay Building has several Moderne features including:

- projecting Tyndall limestone panels with hand-carved historical figures above the entrances;

- Tyndall limestone panels on the upper storeys;

- decorative inset panels on the second floor;

- black granite panels along street level above the main entrances; and

- stainless steel entry doors.

The building was purchased in 2005 through a partnership between UAlberta and the municipal, provincial, and federal governments.5 To accommodate a fourth-floor addition, existing masonry was restored, and selective portions of the remaining anchored stone veneer were demolished.

Over the course of the renovation and restoration, approximately 400 Tyndall stone panels were removed. These panels were categorized, palletized, and transported to the Balmoral Curling Rink on UAlberta’s South Campus where they were stored for six years. In 2011, renovations began on the Balmoral property, which required the removal of the stored Tyndall stone. Fortunately, the announcement of the construction of the ICE building provided a new use for the Tyndall stone panels recovered during the retrofit of this Edmonton landmark.

Innovation Centre for Engineering building

The ICE building is currently under construction and is located between the Chemical and Materials Engineering Building (CMEB) and the Windsor Car Park on UAlberta’s main campus. The new building will provide approximately 26,000 m2 (280,000 sf) of space to support education and research activities in the Faculty of Engineering. Collaboration between the design team facilitated the value engineering of the east elevation by using a portion of the Tyndall stone recovered from the Hudson’s Bay Building being kept in storage at the Balmoral Curling Rink.

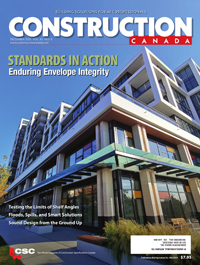

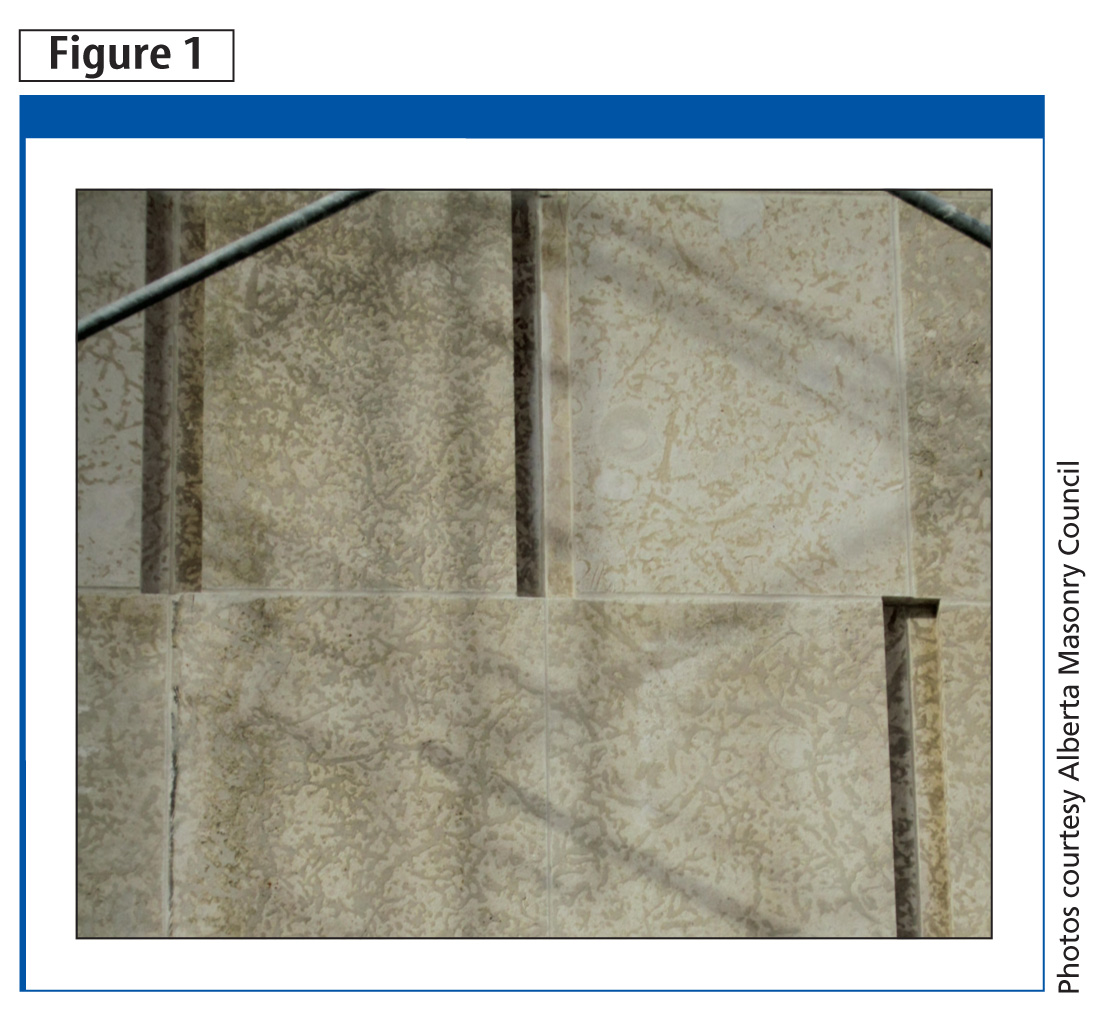

The Tyndall stone panels were cleaned and damaged areas patched with a proprietary mortar specifically designed for restoring limestone (Figure 1). Proper use of the product requires it be scrubbed into the substrate, filling all pores and voids. Using a trowel, the product is forced against the edge of the repair, working the mortar toward the centre. When the mortar is the consistency of dry sand, the area is screeded to the desired finish and the damaged area is patched. After the recycled Tyndall panels had been cleaned and repaired (where necessary), they were matched to the existing chamfered panels on the CMEB by cutting in 50 x 50-mm (2 x 2-in.) chamfers (Figure 2).

Government of Alberta Federal Building

Government of Alberta Federal Building

The 10-story Government of Alberta Federal Building was designed in the Art Deco architectural style in 1939 but construction did not begin until the late 1950s. The provincial government approved the renovation of the vacant structure in 2008 which included a two-storey entry pavilion with gathering spaces, café, and visitor centre and a 650-stall underground parkade to replace the surface parking lots.

The renovation preserved an Edmonton architectural landmark and replaced two parking lots with green space. The scope of the stone veneer work included repointing the existing stone, repair of stone elements, and selective building demolition, including total demolition of the original loading dock. The construction team removed more than 1000 panels from the existing building to accommodate both the 11th floor and Pavilion additions.

The Pavilion addition to the building’s west entrance was constructed with a combination of curtain wall and stone elements and was built for public use. The project also included the construction of gatehouses, which will be used for public washrooms and the storage of maintenance equipment.

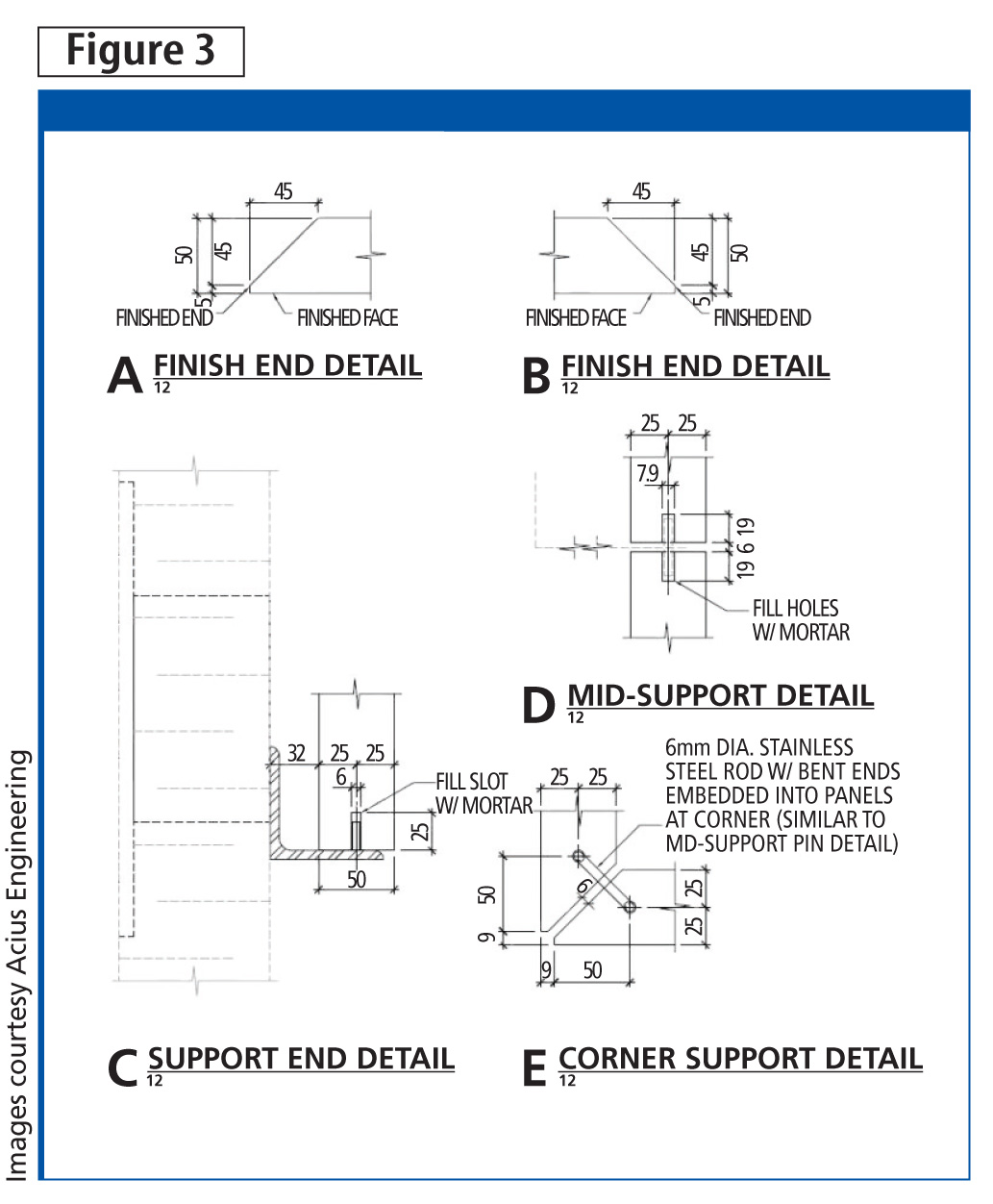

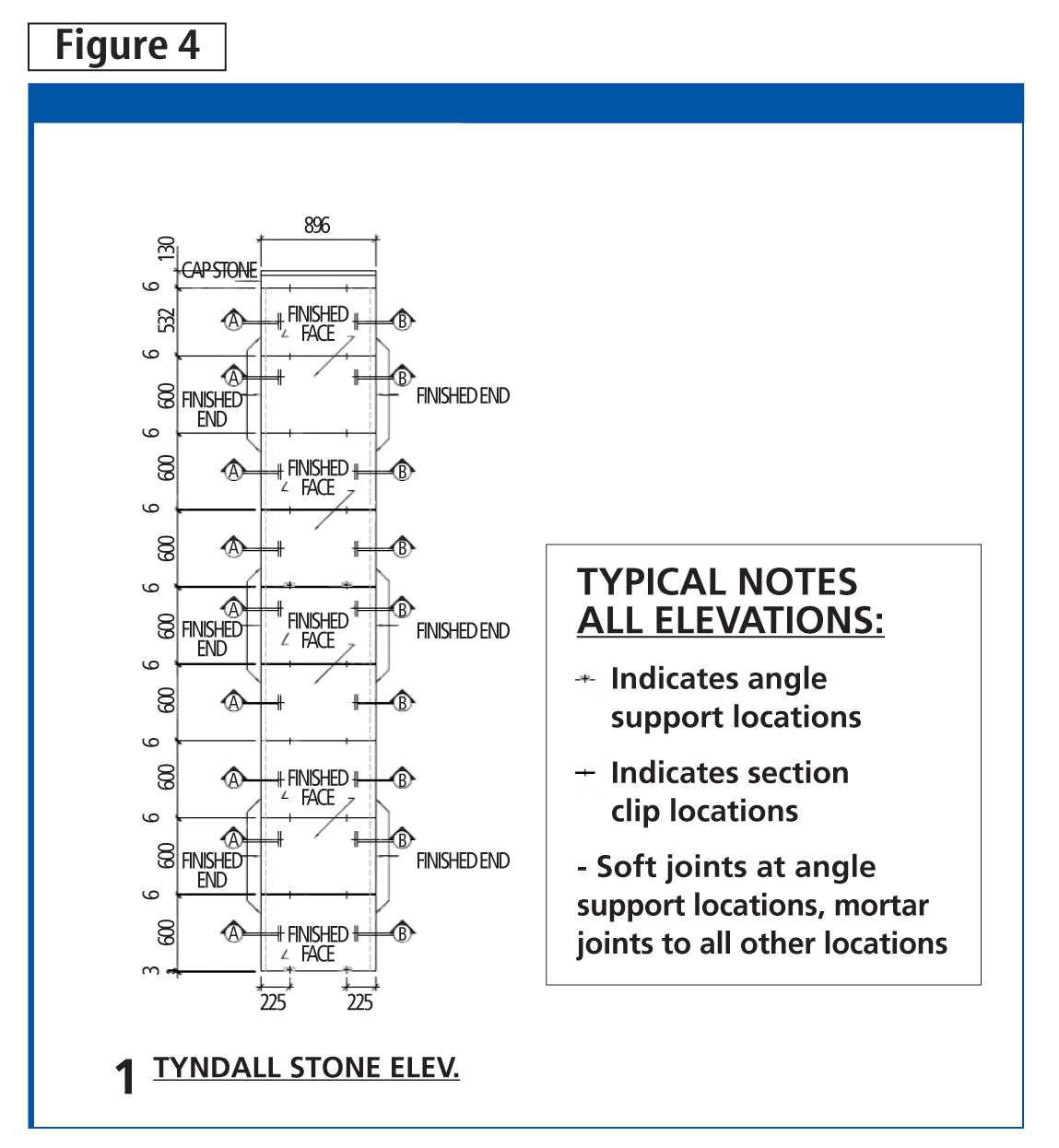

It was suggested the stone recovered from the selective demolition be reconfigured to accommodate these new areas. As with the ICE Building, the Tyndall stone panels were cleaned by pressure-washing them, and then the damaged areas were patched with mortar. Engineering services were employed to design the anchorage system (Figure 3) and provide shop drawings (Figure 4) for the recycled stone.

It was suggested the stone recovered from the selective demolition be reconfigured to accommodate these new areas. As with the ICE Building, the Tyndall stone panels were cleaned by pressure-washing them, and then the damaged areas were patched with mortar. Engineering services were employed to design the anchorage system (Figure 3) and provide shop drawings (Figure 4) for the recycled stone.

The anchor system used grout for the horizontal joints between the Tyndall stone panels and caulking for the vertical joints. The grout allows for load transfer through the joint so stones can bear on one another and be supported at the base using a shelf angle, while caulking the vertical joints allows for differential movement between the stones that are tied back to a steel frame.

One of the greatest challenges faced by the team was to accommodate the thickness of the panels, which had to be cut from large pieces to a 50 mm (2 in.) depth. This required the purchase of one of the largest stone-saws in Western Canada and the construction of a new building to house the equipment. The stone-saw uses a 2.54-m (8.3-ft) diameter blade to cut the stone.

Conclusion

The modular nature of masonry facilitates recycling of this versatile material through reuse and it remains an environmentally conscious and highly durable material. Reusing Tyndall stone on the ICE building and Government of Alberta structure saved the owners time, expense, and energy in the quarry and manufacturing of new stone panels. It also prevented the addition of waste product to landfills. Reusing this stone also resulted in additional LEED points under:

- Materials and Resources (MR) Credit 3, Resource Reuse (salvage);

- MR Credit 5, Local/Regional Materials; and

- MR Credit 8, Durable Building.

It contributed to the awarding of LEED Silver for the ICE building and Gold for the Government of Alberta Federal building.

Notes

1 For more, see Rome: An Oxford Archaeological Guide, by Amanda Claridge et al. (back to top)

2 Visit www.tyndallstone.com/companyindex.html. (back to top)

3 To read more about the original Hudson’s Bay building, visit qa.ideeclic.com/ehc/?q=node/170. (back to top)

4 For more see, www.antiquehome.org/Architectural-Style/modern.htm. (back to top)

5 Visit www.edmontonjournal.com/entertainment/Enterprise+Square+Galleries+seen+exhibit+local+Edmonton/7506853/story.html. (back to top)

Chris Ambrozic is the president of family-owned masonry contractor Scorpio Masonry. He is a licensed journeyman mason and holds a business diploma from Northern Alberta Institute of Technology (NAIT). Ambrozic specializes in masonry restoration and unique masonry projects. He can be reached via e-mail at chris.ambrozic@scorpiomasonry.com.

Mark D. Hagel, PhD, P.Eng., is the executive director of the Alberta Masonry Council. He holds bachelor’s degrees in actuarial science/applied mathematics and civil engineering, and a doctorate in civil engineering. Hagel was previously employed as a technical services engineer for the Canadian Concrete Masonry Producers Association (CCMPA) before moving on to the role of a building envelope engineer and structural engineer with the Calgary office of Halcrow Yolles. Hagel can be reached via e-mail at markhagel@albertamasonrycouncil.ca.