Building the earth sciences building at the University of British Columbia

By Eric Karsh, M.Eng., P.Eng., Struct.Eng, MIStructE, Ing.

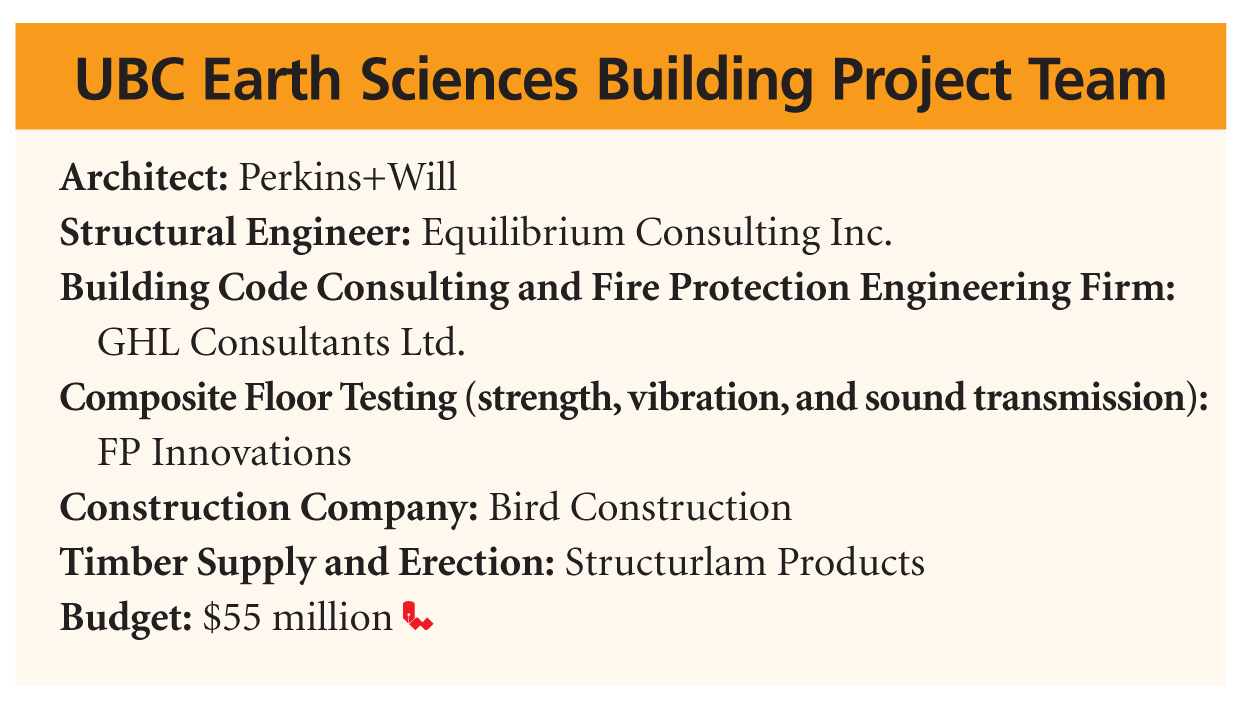

The new 14,864-m2 (160,000-sf) five-storey Earth Sciences Building (ESB) at the University of British Columbia’s (UBC’s) Point Grey Campus in Vancouver is due to open in September. It will house the earth and ocean sciences (EOS), statistics, and mathematic departments, as well as the dean of science. The ESB is a centre of discovery and learning that embodies the academic and physical scope of the UBC campus.

In many ways, it is also a revolutionary structure, thanks to its use of new products and established materials in new ways. ESB provides a snapshot at a pivotal time in the Canadian timber industry; it was designed just as solid wood construction was preparing to enter the local market—anticipated constraints on material availability informed a number of the innovative aspects of the structural system.

The north wing and atrium structure consist of state-of-the-art post-and-beam frames, along with composite and non-composite solid wood panel construction. This wing houses the academic research and administrative programs, as well as three large lecture halls. The link bridge to the adjacent EOS main building and the exterior canopy surrounding the building on three sides are also solid wood panel construction.

The original structural concept for the south wing included a wood-based solution, but was ultimately built with conventional cast-in-place concrete. While analytical work indicated the proposed cross-laminated timber (CLT) based wood-concrete composite system would meet the user’s stringent serviceability requirements, the lack of test data on vibration and sound transmission edged the design toward standard concrete construction.

Special considerations

With innovative designs, it is frequently necessary to address issues that would otherwise have a typical solution. As mentioned, product availability, testing, and certification were significant concerns. Cost is also more difficult to predict when using new systems. In this case, the architectural firm worked closely with the construction team throughout the design phase. This not only helped inform the design team, but also provided the construction team the opportunity to be involved with the design process and be better prepared for the construction phase.

From a technical point of view, extensive vibration and sound transmission performance analysis was carried out by a third party, which also provided full-scale testing of the wood-concrete composite panels and an in-situ vibration testing of the structure. Vibration considerations are particularly critical with solid wood construction as it is much lighter, and sometimes thinner, than cast-in-place concrete systems.

Under the prescribed fire safety requirements for the British Columbia Building Code (BCBC), it was not permitted for the academic wing to be built entirely of heavy timber or wood-frame construction. To allow for the use of wood as the main structural element, an engineering assessment was carried out and documented in a ‘Building Code Alternative Solution,’ which was peer-reviewed as part of the building permits’ approval process.

Innovation

The project includes the following structural elements:

- wood-concrete composite floor system;

- post and beam structure and connections;

- transfer trusses over the lecture theatres;

- exposed CLT roof and canopy;

- ductile chevron braces; and

- cantilevered atrium staircase.

Composite floor system

The structure of the administration and lecture wing consists of glued-laminated (glulam) post and beam frames with three spans of 4.8, 9.6, and 4.8 m (15 4/5, 31 1/2, 15 4/5 ft) in the north-south direction, supporting one-way wood-concrete composite panels spanning 6.4 m (21 ft) between frames. Laminated strand lumber (LSL), typically produced in large sheets—1.22 or 2.44 m wide (4 or 8 ft) and 19.5 m (64 ft) long, and normally with a maximum thickness of 89 mm (3 1/2 in.), which cannot span 6.4 m (21 ft) on its own—was specified for the floor.

As a result, the beams and solid wood panels composite were made with 100-mm (4-in.) concrete topping, which was required to incorporate the radiant heating and cooling system. A 25-mm (1-in.) foamed board insulation layer separates the LSL and topping to help control sound transmission. The insulation also increases the structural depth of the panel without adding weight.

The composite action is achieved using a system consisting of 2.5-mm (1/10-in.) perforated steel plates epoxied into saw cuts in the panel surface and cast into the concrete topping. The plates extend past the insulation layer to support the topping reinforcing. This assembly results in less than half the weight of a comparable concrete structure, significantly reducing foundation and seismic design loads.

Three full-size panel samples were tested at FP Innovations’ UBC laboratory as the composite system had never been used in LSL panels. All samples performed well, reaching maximum capacity by yielding of the perforated plate connectors at an average load of 19 kPa (400 psf)—eight times the required standard office loading. In-situ vibration testing also yielded good results, with minimum floor frequencies in the panel end spans of 9.5 Hz, prior to the installation of the partitions. The results were close to the analytical predictions.

Post and beam connection

Two critical aspects of mid-rise post and beam design and construction are fire resistance and the management of cumulative shrinkage. The strategy used at ESB is centuries old and can still be observed in turn-of-the-century post and beam structures found in most Canadian cities, including many of the original commercial buildings found in Vancouver’s Gastown district such as the Leckie Building, built between 1908 and 1913. The details used at ESB have of course been modernized thanks to the latest in connection systems.

Timber shrinkage is significant perpendicular and tangential to grain, but is small parallel to grain. Wood is also much stronger parallel to grain than perpendicular to grain. The approach is then balloon frame, or to allow columns to be effectively continuous over the full building height.

The interior columns were spliced at each floor but connected directly to each other on end grain with a steel pedestal and cut out in the shape of a saddle to let the floor beams through, forming simple and efficient wood-to-wood connections. The exterior columns were fabricated in double storey heights and the beams were framed into them using a pre-engineered aluminum dovetail connection system typically installed offsite, allowing for fast and accurate erection. The system is inherently fire-resistant as the connector is encapsulated by the surrounding wood.

Full-storey transfer trusses

The north wing incorporates three large lecture theatres that are column-free over the full width of the building. The largest theatre, located to the north, is two-storeys high from the basement to the underside of the second floor. The two smaller theatres are stacked above one another to the south and occupy the ground and second floor.

Full-storey trusses are used to transfer the upper levels across the 19.2-m (63-ft) span, but they could not be fully diagonalized due to circulation requirements, resulting in a partial Vierendeel truss shape. The steel tension diagonals at each end of the trusses are offset from the column work point to allow corridors through. As a result, the bottom chords have to carry high local shear forces and consist of steel-concrete composite-tee sections. The truss-top chords consist of glulam-concrete composite-tee sections. The vertical elements are a continuation of typical glulam columns, forming hybrid composite trusses of steel, concrete, and glulam.

Exposed CLT roof and exterior canopy

CLT was retained in the design of the canopy which wraps around the south end of the building. It was additionally used for the roof and link bridge erected later in the construction schedule.

The expansive 1150-m2 (12,378-sf) canopy appears as a pristinely flat timber plate that emerges from the building and cantilevers past a glulam colonnade, giving the appearance that the entire canopy is made from a single piece of CLT.

The illusion is achieved by locating all supporting beams on top and hanging the panels with self-tapping screws, effectively creating an upside-down structure. The 3-m (9.8-ft) double cantilever corners are strategically reinforced with steel elements located on top or concealed in the depth of the panels.

Ductile chevron braces

The lateral load-resisting system for the north wing consists of a concrete core to the east, and exposed glulam chevron braces along the west façade. Since the glulam braces themselves cannot be allowed to buckle and dissipate energy, the ductility must reside in the connections, which consist of multiple knife plates with many small-diameter, tight-fit stainless steel pins.

The ‘flying’ staircase

Located to the right of the impressive open-concept atrium that links the academic and laboratory wing is a five-storey, free-floating cantilevered solid timber staircase. The dramatic 3.6-m (11.8-ft) wide stair is fully cantilevered off the bridge floors and composed of a seamless folding ‘ribbon’ of rigid glulam plates—the first of its kind. The clean and elegant lines of the massive timber seem to defy gravity, and dramatically demonstrate the esthetic and structural capabilities of modern engineered timber.

The rigid joints are achieved with the system consisting of perforated steel plates epoxied into the timber elements with an adhesive. A 62 x 254-mm (2.4 x 10-in.) steel bar, which remains visible from the underside, strengthens the landing plates across the grain and helps distribute local stresses at the intersection of the stair stringers, where high scissoring forces meet.

Conclusion

The Earth Sciences Building project sets a new standard of structural performance and innovation in heavy timber construction and demonstrates how modern engineered timber can be used efficiently and competitively in the most demanding of institutional projects.

Solid timber and composite floor systems present a great opportunity for the wood industry in the commercial market—especially in multi-storey residential and non-residential buildings. As the building industry looks to lower its environmental footprint, wood is a natural and renewable choice.

Commercial developers are increasingly recognizing advantages of solid and composite wood construction, due to successful projects like ESB. Recently, UBC has decided to implement a similar composite floor system at the newly completed Okanagan Campus Fitness and Wellness Centre in Kelowna.

Eric Karsh, M.Eng., P.Eng., Struct.Eng., MIStructE, Ing., co-founded the structural firm, Equilibrium Consulting, which has worked on award-winning projects such as the Raleigh-Durham Airport expansion and the Art Gallery of Ontario (AGO) Galleria Italia by Architect Frank Gehry. Originally from Québec, Karsh began his structural consulting career in Ottawa in 1987 and moved to Vancouver in 1993, where he was first introduced to timber engineering. Karsh has engineered numerous innovative projects using various forms of solid-wood construction, including Dowling Residence—the first all-cross-laminated timber (CLT) building in North America. He can be contacted via e-mail at info@eqcanada.com.

Eric Karsh, M.Eng., P.Eng., Struct.Eng., MIStructE, Ing., co-founded the structural firm, Equilibrium Consulting, which has worked on award-winning projects such as the Raleigh-Durham Airport expansion and the Art Gallery of Ontario (AGO) Galleria Italia by Architect Frank Gehry. Originally from Québec, Karsh began his structural consulting career in Ottawa in 1987 and moved to Vancouver in 1993, where he was first introduced to timber engineering. Karsh has engineered numerous innovative projects using various forms of solid-wood construction, including Dowling Residence—the first all-cross-laminated timber (CLT) building in North America. He can be contacted via e-mail at info@eqcanada.com.