By Jeff Razwick

The science of daylighting design is to adequately illuminate interiors without imposing additional cooling energy loads. Sunlight entering buildings through glazed assemblies can help reduce electric lighting loads and improve indoor comfort levels. However, over-lit interiors and glass with poor thermal performance can cause adverse side effects like glare, heat loss, and undesired solar heat gain.

Consequently, it is important to develop daylighting plans to balance light distribution and thermal performance. Understanding how glazing can impact the building envelope is a crucial first step in this process. From concept to specification, the following considerations are aimed at helping design teams use glazing to enhance a building’s energy efficiency.

Getting started

Architecture, site orientation, building materials, and lighting systems all affect how well a fenestration system transmits light without undesirable side effects. Taking into account a project’s scope and budget, the Whole Building Design Guide (WBDG) notes successful daylighting design typically includes a combination of the following components:1

- daylight-optimized footprint;

- climate responsive window-to-wall ratio (WWR);

- high-performance glazing;

- daylight-optimized fenestration design;

- skylights (passive or active);

- tubular daylighting devices (TDDs);

- daylight redirection devices;

- solar-shading systems;

- daylight-responsive electric lighting controls; and

- daylight-optimized interior design.

Building teams can identify the best integrated daylighting approach by evaluating the effectiveness of design elements before construction. Today’s advanced modelling software can simulate the sun’s position in relation to a given structure, making it possible to track light levels, glare potential, and climate-based metrics, such as a building’s percentage of operational hours during which daylight levels exceed target criteria. Such information enables teams to better predict glazing placement and size, coatings, shading devices, and energy savings. It also leaves critical time for pre-construction adjustments.

Building questions

While daylighting needs differ by project, the following are questions to ask when analyzing proposed designs.

Is the building footprint optimized for daylighting?

Daylighting design starts with the building footprint. Since there are practical limitations to the amount of light that can be transferred through windows and curtain walls, a building’s footprint can help optimize available daylight. One strategy is to use buildings with shallow floorplates. Restricting the distance from a building’s perimeter to its core reduces the distance light has to travel, improving its transmittance and therefore reducing electrical lighting needs. This is particularly beneficial for buildings with long east-west axes, as openings on the north and south side of a building have better daylight potential and are less susceptible to overheating.2 In buildings with deep floorplates, the core can be lit with the help of atriums, inner courtyards, and toplighting.

Does the glazing maximize available daylight?

A glazed opening is only as beneficial as its access to daylight. There may be trees or nearby buildings obstructing daylight access. Glazing oriented to transfer adequate daylight to working areas can also benefit building occupants. Where possible, the number of south- and north-facing façades should be maximized as they experience less glare and heat buildup issues than east- and west-facing façades. Additionally, since the sun is at a low angle during winter months, south-facing façades and clerestory windows can help capture greater amounts of light than other areas of vertical glazing.3

Placing large, glazed openings with minimal shading controls in entrances, hallways, and perimeter areas where occupants are present for short periods can help maximize useful light. Glazing that diffuses or filters light can provide occupants in offices, classrooms, and rooms beyond the perimeter with well-lit, yet comfortable interiors. Rooms requiring minimal daylight access are ideal for service, mechanical, and storage rooms.

Is the design appropriate for the climate?

In all but the extreme north of Canada, it is possible for interior spaces to receive 15 times more illumination than required to perform typical indoor tasks.4 Therefore, the challenge is not to provide sufficient light for building occupants, but rather to account for heat transfer in a cold climate. Careful specification of glazing, framing, and supplemental shading systems, as discussed in the following sections, can help combat heat loss and minimize summer heat gain (see “Daylighting Pitfalls”).

Is glazing designed for clear or overcast skies?

Design tactics differ for buildings in cloudy regions. Large glazed openings pose less risk for glare and heat transfer in overcast climates since non-direct sunlight is more diffused and therefore easier to control. In climates with predominately direct sunlight, small apertures can provide sufficient illumination, particularly when used in conjunction with reflective sills, diffusing glazing, or high-performance coatings.

Is the window-to-wall ratio balanced?

Identifying the appropriate window-to-wall ratio is crucial to a building’s overall energy-efficiency. The WWR is obtained by taking the net glazing area and dividing it by the gross exterior wall area.

Larger WWRs create a desirable esthetic and can help provide daylight into at least 75 per cent of regularly occupied spaces. This can help design teams earn points towards Canada Green Building Council’s (CaGBC’s) Leadership in Energy and Environmental Design (LEED) rating system under Indoor Environmental Quality (EQ) Credit 8.1, Daylight and Views.

However, since glass typically has lower insulating levels than surrounding materials, estimating the appropriate WWR through software modelling and schematic design is essential to help minimize heat gain and loss through glazed openings. Modelling will also indicate the presence of glare and illumination patterns within a space, helping optimize the placement and size of openings relative to the space’s intended use.

While climate, building orientation, window height, and floor and ceiling reflectance all factor into the appropriate WWR, the Daylighting Guide for Canadian Buildings notes a 30 per cent ratio is typically suitable for general lighting situations. Methods for mitigating heat loss and undesired solar gain in buildings where the WWR exceeds 30 per cent include employing:

- double-skinned façades;

- triple glazing;

- silk-screening;

- glazing infills; and

- high-performance coatings.

Glazing for energy-efficiency

Glazing specification is a crucial next step in creating high-performance building envelopes. Understanding three basic characteristics of glass can help guide appropriate product selection.

U-value

A primary consideration in the specification process is to select glazing with an appropriate U-value. Since glass has lower insulation ratings than many surrounding building materials, it can leave curtain walls, windows, and façades susceptible to excessive heat exchange. Glass with a low U-value can help resolve this dilemma, combating heat transfer and the resulting need for perimeter heating or cooling to ensure occupant comfort near the opening.

One method for achieving a low U-value is to install windows or curtain walls with triple- or quadruple-glazed units. When air is trapped between glass it creates an insulating effect that can significantly reduce heat transfer. To further improve U-values, both laminates and insulated glass (IG) units can incorporate inert-gas fills, such as argon or krypton.5

Another alternative for combating the heat exchange dilemma is channel glass. The individual cast-glass channels are mounted in an overlapping fashion, creating an insulating dead air-filled space and thermal gap. The addition of thermally broken frames and insulators can help building teams achieve a low U-value. For example, adding translucent aerogel insulated insert panels can result in a U-value as low as 0.21 (see “Channel Glass Close-up” below ).

Since centre-of-glass U-values are generally lower than values for whole window assemblies (i.e. glass in conjunction with framing, spacers, etc.), frame selection is crucial to overall thermal performance.

Solar heat gain coefficient

Glass with a lower solar heat gain coefficient (SHGC) better prevents solar heat from passing through its surface. While glass with a low SHGC is ideal for many buildings, in heating-dominated climates, glass with a moderate SHGC might prove more beneficial as solar heat can help warm interiors during the winter.

One method for obtaining the right level of radiant heat transfer is through low-emissivity (low-e) coatings, which typically allow short-wavelength radiation and reflect long-wave radiation. The extent to which a given coating allows or reflects radiation corresponds with its ability to reduce SHGC levels.6

In general, low-e coatings fall into two primary categories—soft and hard. Soft coatings are sprayed onto glass and provide high visible light transmittance (VLT) and low solar heat transfer. Hard coatings are applied during the glass manufacturing process, providing improved durability. Since they have high visible light transmittance and solar gains, they can be a good choice for small commercial buildings (or homes) where heat gain is easier to control.7

Visible light transmittance

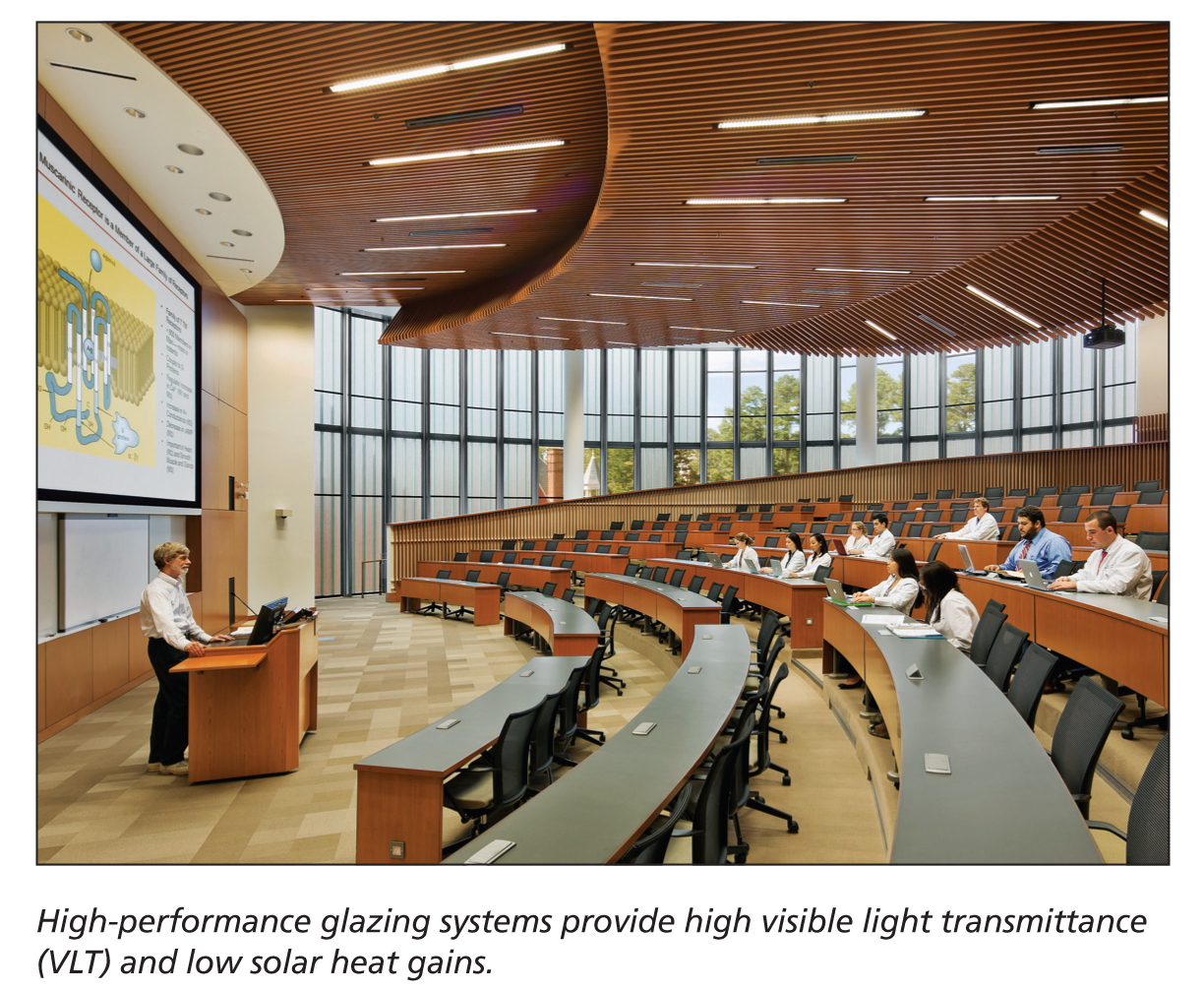

VLT refers to the amount of visible light passing through glazing. High-performance glazing systems admit the most visible light with the least solar heat gain.

Manufacturers offer an increasingly wide array of advanced glazing products to help balance VLT with solar heat gain. Glass with spectral selectivity can respond to different wavelengths of solar energy, meaning it can admit visible light while protecting against infrared heat. To achieve this level of performance, such glazing often incorporates absorbing tints or coatings, and is blue- or green-hued.

Advanced products, such as photochromic and electrochomic glazing, can also balance VLT with solar heat gain. For example, VLT and SHGC change in photochromic glazing according to light exposure, while an electronic current changes VLT and SHGC in electrochromic glazing.8

Additionally, design teams can use translucent glazing materials with a good U-value that diffuses light, such as aerogel-insulated channel glass. This combination of properties can help building teams maximize the amount of space lit by the transmitted light while reducing the contrast causing glare.

Framing for energy-efficiency

Framing anchors glazing within an opening and plays an important role in energy-efficient daylighting design. Most framing systems have high thermal conductivity compared to other elements of the building envelope and are susceptible to summer heat gain and winter heat loss. This remains a challenge even for systems using low-e glass or other energy-efficient glazing, because the thermal efficiency remains substantially less effective where the glazing’s edge meets the supporting frames.

To this end, it is important to ensure framing systems can contribute to energy performance goals or LEED standards. For example, LEED category Energy & Atmosphere (EA) Prerequisite 2, Minimum Energy Performance, outlines the minimum level of energy efficiency for the proposed building through one of three compliance path options.

To this end, it is important to ensure framing systems can contribute to energy performance goals or LEED standards. For example, LEED category Energy & Atmosphere (EA) Prerequisite 2, Minimum Energy Performance, outlines the minimum level of energy efficiency for the proposed building through one of three compliance path options.

One method for improving thermal performance is through warm-edge spacers. Containing few, if any, metal components, insulating spacers can help reduce the glazing’s U-value. The spacers also help keep the inside surface of the frames warm, which in turn reduces condensation. Incorporating thermal breaks (i.e. separations between the inner and outer frames) also helps reduce the heat flow. Generally, wide thermal breaks outperform narrow thermal breaks.

Framing material selection is also an important consideration. Despite conducting significantly more heat than wood and vinyl, aluminum has long been the standard for commercial fenestration systems because of its lightweight nature. In recent years, advanced steel frames have emerged as a high-performance alternative.

Steel’s thermal conductivity is approximately 74 per cent less than aluminum (approximately 32,7000 joule/hour [31 Btu/hour] for steel versus approximately 124,500 joule/hour [118 Btu/hour] for aluminum). This is equivalent to thermally broken aluminum frames. Due to the design of steel profiles, some advanced steel frames do not necessitate a traditional thermal break. This helps lower the potential for heat transfer and interior condensation on the frames by providing a significantly smaller area of metal for heat to pass through.

Steel also expands and contracts at a rate about 50 per cent less than aluminum. Its thermal expansion coefficient of about 12 x 10–6 x 1/K is comparable to glass and concrete, which are approximately 9 and 10 respectively, while aluminum is about 24. Since steel, glass, and concrete expand and contract at similar rates, steel can work in close conjunction with its surrounding materials to help ensure a sound building envelope as the temperature changes.

Another benefit is steel’s strength. The material is three times stiffer than aluminum with a substantially greater load capacity. These properties help ensure modern steel framing is well-suited for high-performance triple- or quadruple-glazed units. Steel’s strength can allow for glass sizes to be up to three times larger in steel frames than in aluminum frames of the same shape.

Another benefit is steel’s strength. The material is three times stiffer than aluminum with a substantially greater load capacity. These properties help ensure modern steel framing is well-suited for high-performance triple- or quadruple-glazed units. Steel’s strength can allow for glass sizes to be up to three times larger in steel frames than in aluminum frames of the same shape.

Depending on product selection, some steel systems can also support glazing infills up to 76 mm (3 in.) thick. By incorporating framing members providing the required support for triple- and quadruple-glazed units, the design team can balance the admission of natural light with energy costs.

As with any material, it is important to check with the manufacturer when using steel framing in areas subject to extreme water or wind. Manufacturers can use high anti-corrosion protection—such as double-sided, pre-galvanization with a factory-applied durable primer and finish colour—to protect against rust. Additionally, gaskets can be incorporated to completely isolate water from contacting the steel components, providing supplemental protection against water intrusion and corrosion.

Conclusion

As energy standards tighten, it will become increasingly important to stay abreast of emerging glazing technologies and daylighting applications. Well-executed daylighting design can ensure stunning spans of glazing provide occupants with optimal illumination, reduce energy use, and help project teams meet green building goals.

Notes

1 For more, see Greg D. Ander, FAIA’s “Daylighting,” obtained from Whole Building Design Guide at www.wbdg.org/resources/daylighting.php. (back to top)

2 See Keith Robertson M. Arch, NSAA, Solterre Design’s Daylighting Guide for Buildings. (back to top)

3 See Note 2. (back to top)

4 For more, see Public Works and Government Services Canada’s Daylighting Guide for Canadian Commercial Buildings, at www.enermodal.com/pdf/DaylightingGuideforCanadianBuildingsFinal6.pdf. (back to top)

5 For more on inert gases, see “Are You Getting What You Paid For?: Quality control techniques for evaluating glazing assemblies.” (back to top)

6 See Note 2. (back to top)

7 See Note 4. (back to top)

8 For more info, visit windows.lbl.gov/daylighting/designguide/designguide.html. (back to top)

Jeff Razwick is president of Technical Glass Products (TGP), a supplier of fire-rated glass and framing systems and specialty architectural glazing. He frequently writes about the design and specification of glazing systems for institutional and commercial buildings, and chairs the Glass Association of North America’s (GANA’s) Fire-rated Glazing Council (FRGC). Razwick can be contacted via e-mail at sales@fireglass.com.

Jeff Razwick is president of Technical Glass Products (TGP), a supplier of fire-rated glass and framing systems and specialty architectural glazing. He frequently writes about the design and specification of glazing systems for institutional and commercial buildings, and chairs the Glass Association of North America’s (GANA’s) Fire-rated Glazing Council (FRGC). Razwick can be contacted via e-mail at sales@fireglass.com.

GREAT POST AS ALWAYS