A Tankless Task: Energy efficiency with on-demand water-heating

By James York

One of the biggest heating and cooling equipment trends of the green movement over the past 10 years has been the growing popularity of tankless—also known as on-demand—water heaters in new construction and retrofit projects across Canada and the United States. A standard in Europe and Asia for more than 40 years, these space-saving, long-lasting systems provide a constant, on-demand supply of clean, hot water for all appliances and water fixtures simultaneously in high-frequency commercial applications when properly sized.

These systems consume less energy than traditional tank water heaters, resulting in lower utility bills. However, to ensure optimal performance, engineering, architecture, and construction professionals must have a good understanding of tankless water heaters—how they function and how to right-size a unit for a particular application. Knowing these fundamentals will help guide clients toward the best water heater choice for a non-residential project.

Condensing and non-condensing

Tankless systems heat water directly from the building’s cold water supply whenever there is a demand for hot water; as their name suggests, they do not store heated water. This sets them apart from traditional tank-style heaters, which typically hold at least 150 L (40 gal) of water at a constant temperature, resulting in standby losses from dissipated heat of up to 20 per cent.1

With tankless water heaters, standby losses are limited or even eliminated. Tankless units generally range in capacity from less than 15 L (4 gal) to more than 42 L (11 gal) of hot water per minute, and vary in efficiency from about 80 to 98 per cent.2 In contrast, many traditional tank water heaters have an efficiency rating of 60 per cent or less.

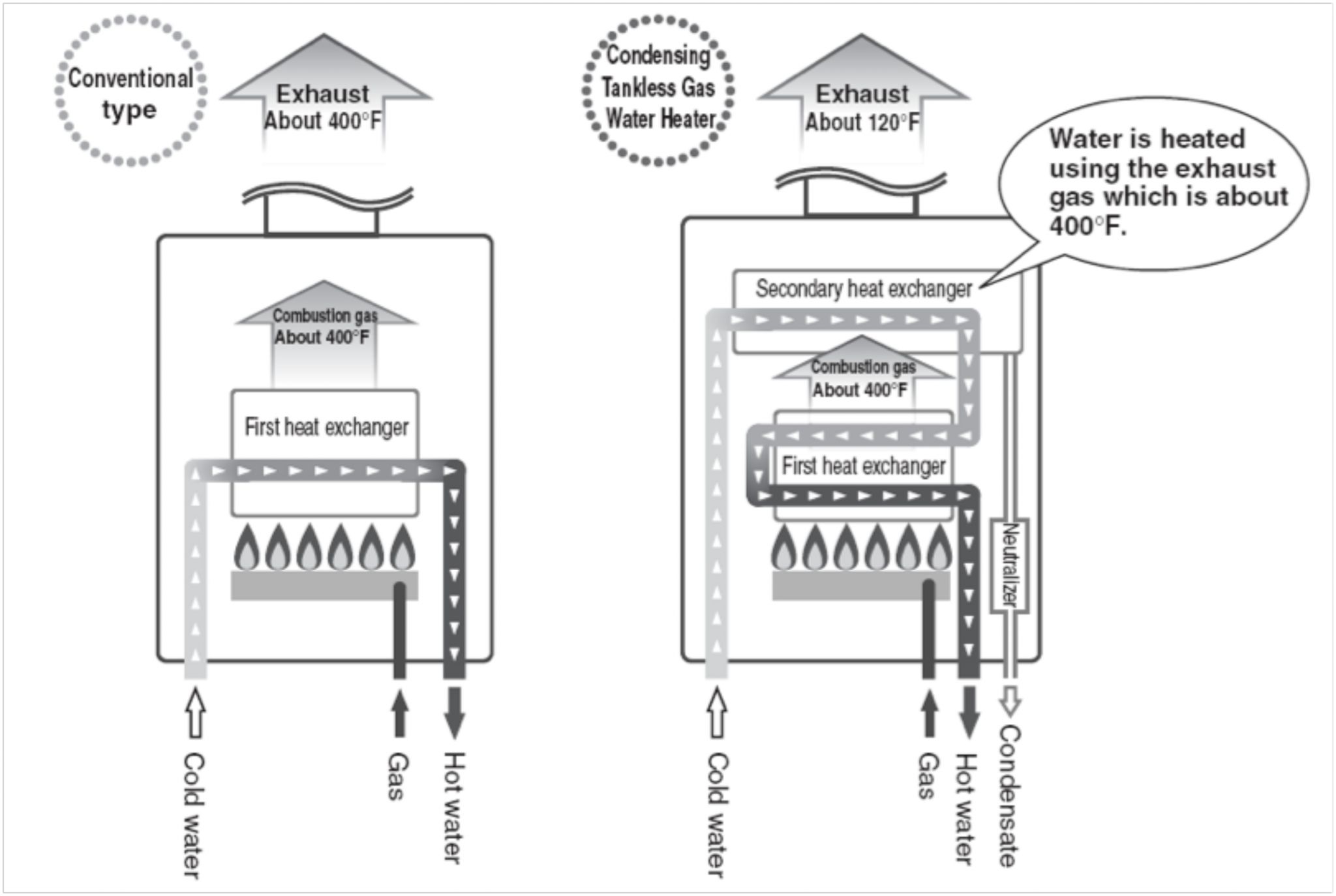

There are two types of tankless systems—non-condensing and condensing. The defining difference between the two is the former has only a primary heat-exchanger, while the latter also has a secondary one. With this dual heat-exchanger format, condensing units use a different exhaust-gas venting strategy than non-condensing units, allowing them to operate more efficiently. Condensing tankless water heaters therefore earn a higher Energy Factor (EF) rating (up to 0.96) than their non-condensing counterparts (up to 0.82).

The foremost unit of measurement for water heater energy efficiency, EF is the ratio of useful energy output from the heater to the total amount of energy input to it. To guide project teams toward the most energy-efficient tankless water heater for their application, Natural Resources Canada (NRCan) provides a searchable database of popular models, listed with their EF ratings online.3

American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 90.1, Energy Standard for Buildings Except Low-rise Residential Buildings, is currently considering a revision to provide guidance for service water applications that require water-heating systems with an output of more than 1,000,000 Btu/h to use condensing water heaters. Replacing a traditional tank-style water heater with a non-condensing tankless water heater will still result in significant energy savings. It is up to facility owners, however, to decide whether they want to invest more money in a condensing tankless water heater for even higher energy efficiency. It all depends on the size of the facility and its water-heating needs. Most often, the larger the condensing tankless water heating system, the larger the return on investment (ROI), justifying a higher upfront cost.

In the case of projects pursuing certification under the Canada Green Building Council’s (CaGBC’s) Leadership in Energy and Environmental Design (LEED Canada) program, project teams also sometimes opt for a condensing tankless water heater instead of a non-condensing unit for the extra energy efficiency points, as it can be a tradeoff for more expensive energy efficiency improvements in other areas of the building.

How do they work?

With tankless systems, whenever a faucet or appliance is set to request hot water, the demand is sensed by a flow sensor, setting the heating process in motion. A temperature sensor inside the tankless water heater then measures the temperature of the incoming cold water to calculate how much heat must be generated to deliver the desired temperature. It communicates this information to the unit’s gas burner, which adjusts its flame to match the demand.

One common myth about tankless water heaters—sometimes incorrectly referred to as ‘instantaneous’—is they deliver hot water immediately to the faucet. Merely replacing a tank-style heater with a tankless one does not reduce the time it takes for hot water to travel to fixtures, unless the project’s engineer or architect takes advantage of the flexibility allowed by the unit’s small size and places it closer to where hot water is most in demand. The shorter the distance between the tankless unit(s) and the outlet requesting hot water, the shorter the wait time.

Since these tankless systems heat water on demand, they require a minimum flow to transfer the heat to the water at the temperature requested. Technological innovations made over the years allow tankless units to operate at flow rates as low as 0.98 L (0.26 gal) per minute.

With non-condensing units, water is heated as it winds back and forth repeatedly through the primary heat exchanger, and the heated water flows into the hot-water outlet pipe and to the water fixtures that have requested it. The resulting exhaust gases are vented directly from the non-condensing unit at a temperature of about 204 C (400 F).

With condensing tankless units, the primary heat exchanger is positioned directly adjacent to the burner and does most of the work of transferring heat from the burning gas to the water. The secondary heat exchanger is located at the exhaust outlet of the primary heat exchanger. Incoming water is pre-heated in the secondary heat exchanger before entering the primary heat exchanger. The secondary heat exchanger captures the exhaust gases and transfers the latent heat to the water. The gases then cool and condense into water vapour, which is directed through a condensation trap into a drain. Therefore, instead of exiting at 204 C, the exhaust gases from a condensing unit are closer to 49 C (120 F) when they are vented.

For both condensing and non-condensing units, the gas-control valve closes when the demand for hot water ends. It remains in standby mode until the need for hot water resumes.

Benefits of tankless water heaters

From their small size to their long-lasting, efficient performance, tankless water heaters have much to offer project teams, as well as end users.

Lower utility costs

Since tankless water heaters are highly energy-efficient, they help project teams meet green building standard goals, and assist owners and operators in reaping significant savings in monthly utility bills. The water stored in traditional heating tanks must be kept hot over long periods, instead of being heated strictly on-demand, as with tankless units. This consumes more energy and creates higher utility bills.

Space savings

Tankless water heaters are small in comparison to their tank-style counterparts, taking up considerably less room—an important consideration in construction environments where space is confined or comes at a high premium. These units are generally the size of a carry-on suitcase, but range from the dimensions of a breadbasket to a medicine cabinet—they can easily be delivered through small doorways. As they are hung on a wall instead of being floor-mounted, they are esthetically better than a traditional tank-style water heater and also have smaller, less conspicuous vent pipe runs.

Redundancy

In commercial applications with high water-volume demands, up to 25 condensing or non-condensing tankless water heaters can be connected to create a banked multi-unit control system, operating as a single source. A multi-unit control system offers the benefit of redundancy, which means that if one, two, or more water heaters require maintenance, the remaining units seamlessly continue providing on-demand hot water service to the facility. This means even if one unit shuts down, the system still operates with approximately 80 to 90 per cent coverage.

These systems are engineered with cyclical unit rotation—they bring only one unit online for a set period, shut it down, and then power up the next unit. This allows all the units to be used evenly and ultimately increases the system’s longevity.

High turndown ratio

In addition to redundancy, specifying a multi-tankless-unit control system presents the added benefit of a higher ‘turndown,’ which is the ratio of maximum fuel input rate to the minimum fuel input rate of a variable input burner. Turndown generally refers to the ability to adjust a water heater’s input to meet the real-time heating demand of the system without an overshoot in temperature or wasteful cycling. The higher the turndown ratio, the greater the efficiency of the tankless system.

With a multi-unit system, the modulator turns units on or off to precisely meet the demands of the commercial application. This allows the system to have a turndown ranging anywhere from 10,000 to 5 million Btus. Most standard 100-gallon tank-style water heaters in commercial applications do not have a turndown ratio—burners come on at 199,000 Btus per hour and run until all the water in the tank is hot.

Top-down burners

Some models of condensing tankless systems are engineered with top-down burners, which enhance product longevity by ensuring any condensation in the exhaust is quickly captured and diverted to a drain.

A wide variety of applications

There are several commercial applications where tankless water heaters would prove beneficial, including hospitality, food service, schools, and carwashes. Whether an architect or engineer needs energy-efficient water-heating for a small fast-food restaurant or a large luxury hotel, there is virtually always a fitting solution to be found through tankless technology. Further, the upfront cost of a tankless system can be equal to or less than the cost of a commercial tank-style assembly, and installation costs are usually comparable.

Due to the energy and space savings building owners recoup from tankless technology, incorporating one or more tankless heaters is suitable for all commercial water-heating applications. The technology assists specifiers and construction professionals, specifically in replacement or retrofit applications. For example, large commercial tank-style water heaters are sometimes placed in new buildings, with walls constructed around the system. When the time comes to replace the large unit, it can be extremely difficult to remove and install the new unit(s).

Due to their compact size and much lighter weight, tankless water heaters, in contrast, allow for a much easier installation—they can easily be carried through doorways by one or two installers. A simpler installation is almost always a more economical installation in the end. Large tankless water-heating systems can bring some challenges with piping and venting arrangements, however.

Further, facilities that have periodic high-volume, short-duration water draws might favour storage tank water heaters if the high-volume water dump increases the requirements of the tankless system beyond the normal sizing. A good example of this would be a business that sprays down its floors at the end of the day with a fire hose (consuming a high volume of water), but, on average, uses much less water throughout the rest of the day. In these applications, the business owner may want to add a storage tank to an existing tankless system to handle the high-volume water dump or install a lone gas-powered storage tank.

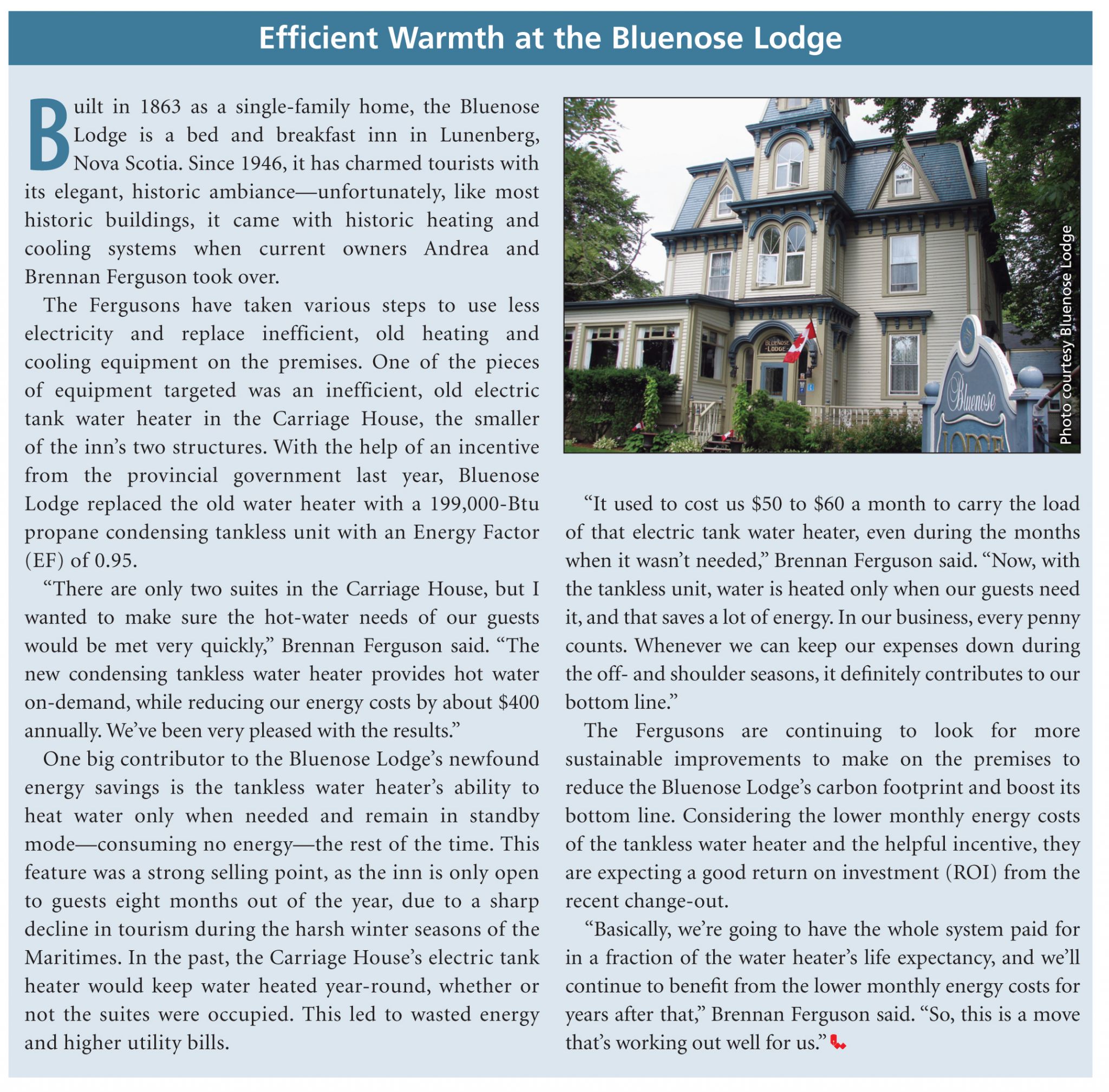

Hospitality

With multiple guests often using hot water simultaneously, it can be challenging for even small bed-and-breakfast locations and hotels to keep up with the demands using traditional tank water heaters. (Of course, if they want good reviews and return business, it is imperative to keep guests happy.) With tankless systems, hotels can rest assured guests and housekeeping staff will always have hot water whenever they need it at lower utility costs than its tank counterpart. The same benefits experienced by the hospitality industry will likely be noticed in long-term-living and college-dormitory applications.

Food service

High volumes of hot water are a necessity for daily restaurant operations. Too long of a wait for hot water means fewer clean dishes and cookware, resulting in slow service and disgruntled customers. Condensing tankless units are ideal for restaurants and other businesses that use large volumes of hot water, as they offer the best energy efficiencies and the most positive impact to the bottom line. Further, restaurants especially benefit from the smaller size of tankless water heaters—commercial space is expensive, and having room available can allow more customers to be served.

Schools

Schools

Schools have high-volume hot water needs during daytime hours, with locker-room showers and cafeterias serving hundreds of students, but then spending the rest of the day inactive. Using tankless water heaters instead of tank systems conserves energy by ensuring water is heated only when needed—not at intervals throughout the entire day. Many schools also have a tight operational budget, so being able to meet all hot-water demands more energy efficiently with equipment that typically lasts longer than the traditional alternative can be a big advantage.

Carwashes

Carwashes demand a steady stream of hot water to keep the vehicles moving through at a steady pace. Tankless water heaters can meet this demand during customer visits and then go into standby, versus keeping water hot when there are no customers. This saves energy and reduces utility costs, helping the carwash owner’s bottom line.

Conclusion

For optimal performance and efficiency, it is important for the project’s architect or mechanical engineer to choose an appropriately sized tankless water heater(s) for the specific application. This depends on various factors, such as the number of dishwashers, clothes-washers, commercial sinks, and other fixtures, as well as any information about washrooms, showers, or other on-premises equipment requiring hot water. It will also be important to know the typical water demands of the facility and any special water-temperature requirements the client might have.

Specifying tankless systems for clients needing high volumes of hot water on a daily basis is a mutually beneficial move. It can help the project team meet the energy efficiency requirements and solve many water-heating problems for the client. Tankless water heaters can help the client consume less energy, reduce utility bills, use space more efficiently, and keep its customers happy with endless on-demand hot water.

Notes

1 For more information, see the website of C3—an Alberta-based group encouraging energy efficiency and small-scale alternative energy use in the province. Visit www.climatechangecentral.com/take-action/individual/energy-efficiency/water/tankless-water heaters. (back to top)

2 See note 1. (back to top)

3 Visit oee.nrcan.gc.ca/pml-lmp/index.cfm?action=app.search-recherche&appliance=WATERHEATER_T. (back to top)

James York is vice-president of engineering for the Rinnai America Corp., and responsible for overseeing all aspects of engineering, including product development and certification, applications architect, quality control, technical literature development, international liaison, and the company’s laboratory. He has managed the design and construction of a Canadian Standards Association (CSA)-accredited product certification laboratory, and holds multiple patents. York is an active member of the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and CSA; he is the deputy chair of the Air Conditioning, Heating and Refrigeration Institute (AHRI). York can be contacted via e-mail at jyork@rinnai.us.

James York is vice-president of engineering for the Rinnai America Corp., and responsible for overseeing all aspects of engineering, including product development and certification, applications architect, quality control, technical literature development, international liaison, and the company’s laboratory. He has managed the design and construction of a Canadian Standards Association (CSA)-accredited product certification laboratory, and holds multiple patents. York is an active member of the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and CSA; he is the deputy chair of the Air Conditioning, Heating and Refrigeration Institute (AHRI). York can be contacted via e-mail at jyork@rinnai.us.