Image courtesy the Metals Company

Bjarke Ingels Group (BIG) and the Metals Company unveiled designs for seafloor mineral collector robots, carbon-neutral vessels, and waste-free metals processing and recycling plants that will enable a circular supply chain for battery metals.

“Deep-water ports around the world are often degraded ecosystems unwelcoming to local communities. We asked BIG to reimagine what a metals-processing facility could be, to have it integrate with—even remediate—the urban coastal environment,” said Gerard Barron, the Metals Company CEO. “The result is a breathtaking innovation complex that will transform an industrial port into a community-based hub for the electric vehicle [EV] revolution.”

The Metals Company’s challenge with BIG was to bring innovative, whole-systems design to the industrial components needed to supply the world with critical battery metals from polymetallic nodules—fist-sized rocks containing battery-grade nickel, cobalt, copper, and manganese—while reimagining the nexus of industry and community, the company said in a press release. BIG delivered an integrated suite of assets working together to lift nodules off the seafloor and up to a purpose-built production vessel, transfer them to a hydrodynamic shuttle carrier, and onward to a metallurgical plant designed to transform an urban port site into a battery materials innovation and community hub, set within a regenerative coastal landscape.

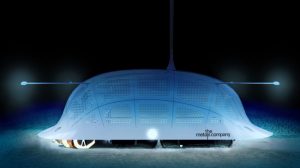

“To collect the nodules, we have designed a light-touch, robotic collector vehicle that aims a jet of seawater across the tops of the rocks to gently pry them from the sediment. Part of our design for future collectors includes a buoyant, hydrodynamic shell with an extended lip to minimize seafloor compaction and reduce and redirect the dust plume kicked up during nodule collection,” said Daniel Sundlin, BIG partner.

The Metals Company’s first-generation collector vehicle has been engineered and is currently being built by Allseas in the Netherlands to be deployed for testing early next year.

Nodules are transported through a flexible hose at the top of the collector vehicle to a rigid riser pipe where they are lifted on compressed air bubbles around 4 km (2.5 mi) up to the surface production vessel, a 216-m (709-ft) long ship running on carbon-neutral electrofuels, with a sunken deck that is covered with photovoltaic (PV) solar panels. The design of the production vessel is driven by functionality. Equipment for nodule collection is strategically packed in the hull to minimize the size of the vessel and maximize operational efficiency. At scale, each production vessel would operate multiple collectors with additional maintenance capacity provided by a support vessel with a ‘moon pool’ for deploying and retrieving collector vehicles.

While the Metals Company’s first production vessel is a deep-water drillship repurposed by Allseas to enable pilot nodule collection, BIG’s next generation vessel design is central to the Metals Company’s plans to scale to a fleet of 10 production vessels, enabling the provision of over 40 million tonnes of battery metals by 2050, enough to produce 280 million EVs.

At full-scale operations, nodules will be transferred from the production vessels to shuttle carriers, whose X-bow design was chosen by BIG to deliver hyper-efficient, hydrodynamic ships to assist the Metals Company in lowering the carbon footprint of its battery metals. Once at port, the nodules are offloaded onto a conveyor and into a portside processing plant—designed by BIG as a sustainable, performative, and social campus in a regenerative landscape.