By Pamela M. Shinkoda, P.Eng., CSC

In this author’s role as a technical solutions manager with a gypsum wallboard manufacturer, a lot of questions are received about fire-resistance-rated wall partitions and floor-ceilings. (This article was written with the assistance of Abbas Nanji, M.S., P.Eng., a senior staff engineer at Underwriters Laboratories [UL] who has been with the organization for nearly 19 years. In his role, Nanji interacts with manufacturers to ascertain their code conformance requirements for building construction materials and assemblies. He is a member of ASTM E5 Committee on Fire Standards.) Inquiries usually begin with “Can I do this?” or “Do we have to do that?” Some of the questions require a lot of research to answer, while others get quick responses. Regardless, over many years in this position, it has become clear not everyone is familiar with the Guide Information for Fire-resistance Ratings section of the Underwriters Laboratories (UL) and Underwriters Laboratories of Canada (ULC) Online Certification Directories.

To that end, this article summarizes the answers to common questions, all of which can be found in either the ULC or UL Guide Information for Fire-resistance Ratings. (In previous printed versions of the Fire Resistance Directory, this section was at the front of the guide.) (The answers provided in this document are not UL’s official position but selected extracts from UL’s publication referenced herein. One should refer to UL’s website—www.ul.com—for the most updated and complete information.)

Images courtesy ULC

Learning the ULC guide

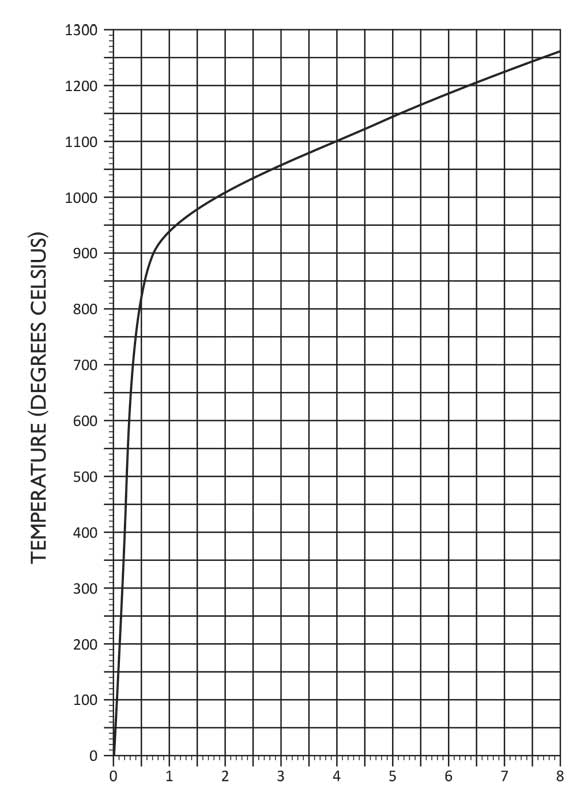

A method of establishing a fire-resistance rating of a wall partition or floor-ceiling, complying with the National Building Code of Canada (NBC) requirements, is determined by the assembly’s hourly performance. The evaluation is based on the results of tests conducted in conformance with CAN/ULC-S101, Fire Endurance Tests of Building Construction and Materials (Figure 1). (If a design is labelled as ‘Certified for Canada,’ this means it can be used in Canada because it was tested to CAN/ULC-S101, Fire Endurance Tests of Building Construction and Materials.)

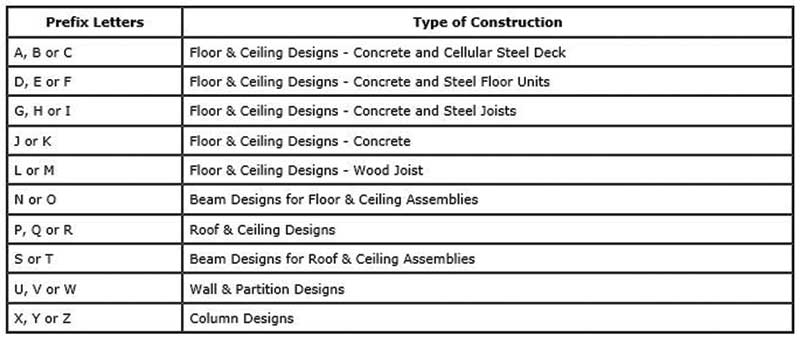

As shown in Figure 2, the ULC and UL designs are a letter/number combination. There are more comprehensive tables that explain this in greater detail. For example, tables are available showing the ULC R200 series describes designs for roof assemblies with an exposed ceiling grid, while ULC R500 series designs describe gypsum board ceiling assemblies.

The answers to the following questions are all ‘yes:’

- “If the ULC design shows framing at 600 mm (24 in.) on centre (o.c.), can we change it to 400 mm (16 in.) o.c. without changing the fire resistance rating?”

- “We put the screws 200 mm (8 in.) o.c. and the ULC design says 300 mm (12 in.) o.c.—is that OK?”

- “The ULC design only requires one layer of board on each side, but the designer wants two layers of board on the one side to improve acoustics—can that be done?”

- “The ULC design shows 89-mm (3 ½-in.) studs—is it all right to use 152-mm (6-in.) studs for height limitation reasons?”

Although the language is not simple in the Guide Information for Fire-resistance Ratings, it is all there:

With the exception of support (e.g. studs) and fastener (e.g. nails, screws) spacings, the dimensions indicated in the following designs are intended to be construed as the minimum allowable for each rated assembly. Support and fastener spacings stated are the maximum allowable. Additional layers of gypsum board are permitted to be added to any design.

Gaining efficiencies on the jobsite

In reference to ULC wall designs, the guide includes the limitations and acceptable allowances for adding insulation to meet acoustical requirements when a ULC wall design does not include insulation, explaining which type of fibrous insulation is permitted and under what conditions. For wall assemblies, wood stud depth can be increased, as can steel stud dimensions and gauges, along with chase wall depths.

For floor-ceiling systems, the guide offers similar information about increasing dimensions. It also provides clarification that older designs often cite use of nails, but screws “may be substituted for nails, one for one, when the head diameter, length, and spacing [are] equal or exceed the requirements for the specified nails.” Further, the guide includes a recent addition explaining the difference between Type X and proprietary Type X gypsum board products (often referred to as Type C).