By Jean-François Côté, PhD, OCQ

When this author joined the roofing industry toward the end of 1999, the standard for modified bitumen (mod-bit) sheets was Canadian General Standards Board (CGSB) 37-GP-56M, Membrane, Modified, Bituminous, Prefabricated, and Reinforced for Roofing; the National Building Code of Canada (NBC), along with many provincial codes, was referencing it in Sections 5 and 9. However, it is important to remember this standard was published in 1980 and updated for the last time in 1985. In other words, it has remained stagnant for more than 30 years.

The CGSB committee met regularly throughout the 1990s to revise this standard. Numerous drafts of an update were reviewed—despite the efforts, though, consensus could not be achieved. Following these unsuccessful attempts, the CGSB roofing committee went dormant around 1998. Several attempts to re-activate it failed and 45 CGSB standards from the “roofing and waterproofing materials” series (i.e. #37) were withdrawn in early 2005 due to a lack of interest. The list included standards for roof cements, coatings, primers, and membranes, but 37-GP-56 was not part of the list.

Over the following eight years, the CSA A123 technical committee repeatedly attempted to obtain the responsibility and jurisdiction of the mod-bit roofing standard from CGSB. Their request was finally granted, and in February 2013, CGSB officially announced the withdrawal of 37-GP-56. Within months, a new CSA task group was formed with the objective of developing a new standard for modified-bitumen roofing membranes. The task group work culminated with the publication of CSA A123.23-15, Product Specification for Polymer-Modified Bitumen Sheet, Prefabricated and Reinforced. It was released in August 2015—30 years after the latest update of its predecessor.

A standard with a wide scope

The new standard covers various types of polymer-modified bitumen sheets used in roofing. Its scope and classifications include products manufactured with styrene-butadiene-styrene (SBS)-modified bitumen as well as atactic polypropylene (APP)-modified bitumen, using one of the three common reinforcement types encountered today in North America:

- glass fibre (Type A);

- polyester fibre (Type B); and

- a combination of both (Type C).

Sheets can then be classified as:

- Grade 1 (granule-surfaced sheets that are intended to be exposed);

- Grade 2 (exposed sheets surfaced with any other surfacing or unsurfaced); or

- Grade 3 (sheets not intended to be exposed).

Several participants of the CSA task group insisted on developing an all-inclusive standard, out of consideration for the users of these products. Specification writers and contractors now only have to worry about a single document that covers the same range of products as six different ASTM specifications. Realizing the similarities between the Canadian and U.S. markets, the task group also opted to require testing to existing ASTM test methods within A123.23. Manufacturers who qualify their products to ASTM specifications already have test reports useful for compliance with the new CSA standard, provided they meet the Canadian requirements of A123.23.

When determining the minimum performance requirements in the standard, care was taken to ensure the performance levels offered by meeting the former 37-GP-56 were maintained. CSA A123.23-15 is therefore at least equally stringent as its predecessor in all aspects, even though some performance requirements were ‘modernized.’

Return of strain energy

The greatest portion of modernity brought by CSA A123.21-15 is the formal integration of the strain energy concept into a national standard of Canada. Efforts made in the 1980s by researchers of the National Research Council of Canada (NRC) to capture mechanical performance of roof membranes (i.e. load and elongation) using a single result were intended to be included in the revised CGSB standard and strain energy was present in the later drafts. Many manufacturers of polymer-modified bitumen membranes opted to include such ‘strain energy values’ in their data sheets over the last 10 years.

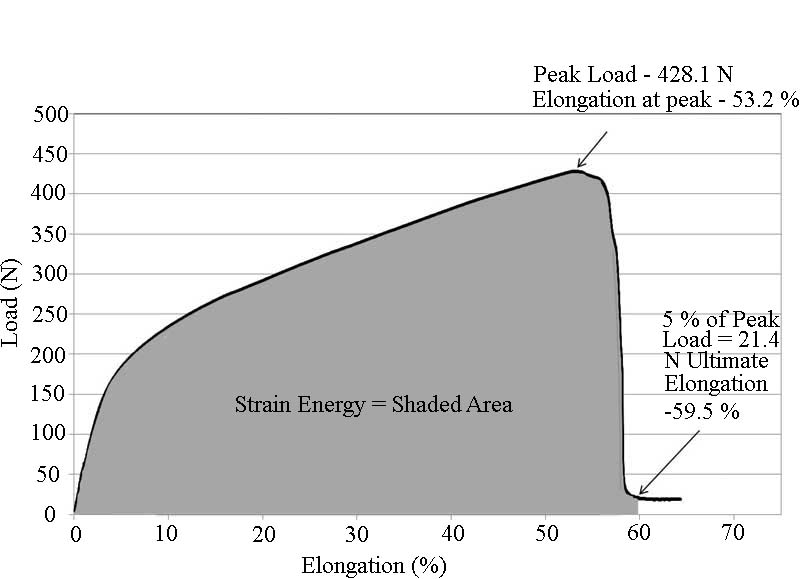

Strain energy applied to roofing membranes can be defined as the energy a membrane specimen can absorb as a result of its deformation before it ruptures and fails. This measurement is helpful in comparing roofing sheets that are very strong, but provide low elongation to other sheets that are not as strong, but offer significantly higher elongation before they rupture. In the context of a laboratory evaluation, strain energy is simply calculated as the

area under the load-deformation curve up to a point where the load-deformation curve drops below a value equal to five per cent of the peak load. Figure 1 illustrates how strain energy is obtained from a typical load-deformation curve.

Minimum requirements for strain energy have been integrated in the tables of CSA A123.23-15 for Type B and C sheets. The values were based on those found in the well-known ‘ninth draft’ revision of the former CGSB document. (Several manufacturers of polymer-modified bitumen membranes recognized the former CGSB standard was outdated. It became common practice for them to publish test results according to the 9th draft of CGSB in their product data sheets. Even though this document had not been approved and was not listed in any building code, it became a reference for those involved with mod-bit sheets in the Canadian roofing industry). As a courtesy to users of the standard unfamiliar with strain energy, CSA A123.23-15 will require manufacturers to disclose (without imposing any target value) peak load, elongation at peak load, and ultimate elongation results, in addition to meeting the strain energy requirements. However, this will not represent additional testing expense—all these properties are obtained during the same test procedure.

On the other hand, the strain energy of Type A sheets (reinforced with glass fibres) was less studied over the years. Therefore, limited data is available to establish a minimum value. For Type A sheets, minimum values of peak load, elongation at peak load and ultimate elongation are imposed by the new CSA standard. Manufacturers will also be required to report strain energy numbers for their sheets (without having to meet a minimum number). This exercise will generate data for the next revision of the CSA standard that will most likely be modified so all types of polymer-modified bitumen sheet materials will have minimum strain energy values to meet.

Testing for the long-term

Calling durability of construction materials ‘important’ to industry stakeholders would be an understatement. Canadian roofs need to perform adequately from the day they are installed until they reach their expected end of life. CSA A123.23-15 recognizes this fact and roofing sheets will be tested for the aforementioned load-strain tests in both directions (longitudinal and transverse), at two test temperatures (23 and −18 C [73 and 0 F]), both before and after a 90-day heat-conditioning. That procedure provides accelerated aging of the sheets and is intended to expose them, in a relatively short amount of time, to conditions simulating the degradation they will be subjected to during their service life.

Possessing low temperature flexibility—a critical property in northern climates—will also require testing by the new CSA standard. Roofing sheets will not only be tested ‘as manufactured,’ but also after the heat-conditioning procedure. During their service life, sheets intended to be exposed (cap sheets) are expected to resist the attack of ultraviolet (UV) radiation. In order to meet CSA A123.23-15, these sheets will have to undergo additional accelerated weathering exposure to UV in a xenon-arc weathering equipment and be tested for low temperature flexibility after this exposure. This will ensure their UV protection mechanism is efficient and durable, whether through the use of mineral granules covering the bitumen compound or by using UV-resistant ingredients in the compound.

Conclusion

After several years of inactivity, Canada’s roofing industry has finally caught up with the 21st century with respect to these types of mod-bit assemblies. The old and obsolete Canadian General Standards Board standard for polymer-modified bitumen roof membranes can now rest in peace in design/construction professionals’ archives.

Specification writers should familiarize themselves with CSA A123.23-15 and start using it in their projects, as it is far more representative of polymer-modified bitumen membranes used in Canada today than the former CGSB document. Doing so will allow them to be ahead of the curve as a code change request has already been submitted, and it can be expected CSA A123.23-15 will be listed as an applicable standard in the 2020 edition of the NBC.

While it will obviously take some time before it can be implemented and enforced, in the meantime, one can look for some CSA reporting in product data sheets as manufacturers will start testing as per the new standard. In fact, the CSA A123 technical committee already has plans for its future edition. In addition to consolidating the strain energy requirements for Type A sheets, testing at lower temperatures and more specific consideration for testing self-adhesive sheets will be reviewed for potential inclusion.

Jean-François Côté, PhD, OCQ, is the director of standards and scientific affairs for Soprema. A registered chemist in Québec, he chaired the CSA task group responsible for the development of CSA A123.23. Côté is also an active member of ASTM International, Asphalt Roofing Manufacturers Association (ARMA), Polyisocyanurate Insulation Manufacturers Association (PIMA), Single-ply Roofing Industry (SPRI), and ULC. He can be reached at jfcote@soprema.ca.

Jean-François Côté, PhD, OCQ, is the director of standards and scientific affairs for Soprema. A registered chemist in Québec, he chaired the CSA task group responsible for the development of CSA A123.23. Côté is also an active member of ASTM International, Asphalt Roofing Manufacturers Association (ARMA), Polyisocyanurate Insulation Manufacturers Association (PIMA), Single-ply Roofing Industry (SPRI), and ULC. He can be reached at jfcote@soprema.ca.