The Sky’s The Limit: Designing airports with wood

By Eric Karsh, M.Eng., P.Eng., Struct.Eng., MIStructE, Ing.

Before the 1850s, wood was commonly used as a primary structural building material in myriad types of non-residential construction around the world. Many of these timber-built structures remain standing and are still in use today, including factories, warehouses, schools, temples, and churches—some dating as far back as the seventh century (e.g. the 32.5-m [107-ft] high Horyu-ji Temple in Nara, Japan), demonstrating the durability and strength of building with wood.

However, the construction of landmark projects such as the Eiffel Tower in 1887 and the Empire State Building in 1929, in addition to technical steel and concrete advances during the industrial revolution, quickly resulted in those materials becoming the default structural choices for large public building construction. Timber engineering has experienced rapid and transformative advances over the past two or three decades, and continues to quickly evolve, making it ready for a comeback.

Many architects and engineers evaluate wood as a viable alternative for the construction of large-scale, non-residential structures. Technical advancements—including new engineered wood products, computer-numerical-controlled (CNC) fabrication, versatile high-efficiency timber connectors, and progress in fire engineering—have contributed significantly to timber’s rise to the forefront of the industry as a construction material. The cost advantages of wood construction are also changing as a result. Further, as the world’s population continues to grow, there is renewed architectural interest in taller buildings made of wood, now made possible by the development of solid wood construction.

Photo © Nic Lehoux

Several recent global studies indicate timber structures exceeding 15 storeys (possibly reaching 30) could soon become reality. This trend has also been spurred in part by the need to use sustainable materials in construction; wood is the only major building material that grows naturally and is renewable. Lifecycle assessment (LCA) studies also consistently show wood products can offer clear environmental advantages over concrete and steel in terms of embodied energy, air/water pollution, and greenhouse gas (GHG) emissions. (For more information on wood and environmental attributes, see the article, “A Deeper Shade of Green: Using Wood as a Sustainable Structural Material,” by Michelle Kam-Biron, SE, and Lisa Podesto, PE, in the November 2010 issue of Construction Canada. Visit www.constructioncanada.net and select “Archives.”)

As buildings that introduce visitors to a community and welcome residents home, airport facilities’ architectural design is critically important. The examples in this article showcase wood as a primary structural building material in significantly large spaces, demonstrating its versatility, cost-effectiveness, ability to meet code, and potential to bring warmth and a connection with the natural world through design.

Cranbrook/Canadian Rockies International Airport

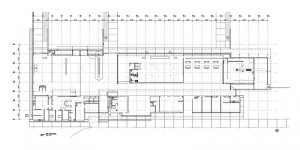

Cranbrook is a small community located near the south end of the Alberta–British Columbia border. In 2006, a significant terminal building expansion of the existing 1970s facility was commissioned to accommodate larger aircrafts and more passengers. These changes included an extension to the existing runway and an expansion of the terminal building, along with a series of upgrades to the fuelling, baggage handling, and related operational areas. Of significant interest is the Canada Customs and Immigrations facility, upgraded to ensure timely processing of international passengers. Completed in 2008, the new terminal building expansion has an area of 2044 m2 (22,000 sf).

The existing terminal, considered small by airport standards, was one of a few B.C. airport facilities built in the 1970s with light wood-frame construction. The original structure consists of an open-steel-web engineered wood truss roof on load-bearing masonry walls and piers. The main floor structure, framed over a partial basement and crawl space, also consists of light wood framing.

The airport had to remain operational throughout construction of the expansion, adding considerable complexity to the work. The $6.3-million project was rolled out in a three-phase timeline:

- construction of the new arrival lounge and customs facility to the west;

- construction of the outbound baggage-handling facility to the west; and

- renovation of the original building, including ticketing, service areas, security, and a new departure lounge.

The design team chose light wood-frame construction for several reasons, including the material’s economy, flexibility, lightness, and compatibility with the original structure. Several architecturally expressed structural steel elements were introduced to replace the masonry walls and piers, opening up the air-side façade. The new facility is mostly made of glass and wood to ensure the stunning landscape of the Rocky Mountains is prominently positioned for viewing.

Prince George Airport

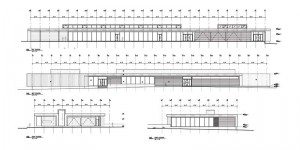

Prince George is a mid-sized, forestry-based community located in central British Columbia. Its airport serves as a hub to the Canadian Northwest and handles a significant amount of regional and international commercial traffic, linking the eastern provinces to Asia. The city also attracts the tourism industry and welcomes numerous flights of outdoor enthusiasts from North America and Europe.

Built in 1970, the original airport structure consists of load-bearing masonry walls and piers, along with a structural steel main floor and roof structure. Given the local connection to forestry, the airport authority wanted to introduce timber as the primary structural material in the two-phase expansion. Using wood in the airport was a way to represent the community and showcase Prince George’s identity and values.

The first phase of the McFarlane Green expansion included adding a departure lounge and baggage handling facility on the airside, north of the original facility; it consists of Douglas fir glued-laminated (glulam) timber post-and-beam construction. The second phase, to the west of the original terminal, includes the addition of an international arrival area on the airside, also constructed with glulam post and beam. For structural and architectural reasons, steel was used for the customs office to the south.