Saving energy through air filtration

By Chris Willette

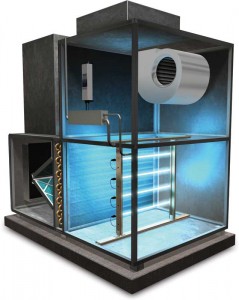

Indoor air quality (IAQ) technologies combining ultraviolet germicidal irradiation (UVGI) and gas-phase purification allow engineers and facility managers to reduce energy consumption while ensuring a safe environment for building occupants. (For more on gas-phase technology, see the article “Improving Indoor Pool Air Quality” by Harry Topikian, P.Eng., in the March 2010 issue of Construction Canada. To read it online, visit www.constructioncanada.net and select “Archives.”) Now, the latest approach is to combine these systems with photocatalytic oxidation (PCO)—a chemical reaction caused by shining UV light onto a reactive medium, usually titanium dioxide.

IAQ equipment manufacturers have combined UVGI, gas-phase air purification, and PCO in a combined filtration unit that can be installed into new or existing HVAC systems. The result offers commercial building owners the potential for significant energy savings.

This new approach can improve energy efficiency in three ways. First, UVGI can cut HVAC coil maintenance costs and retain optimal heat transfer of the coils allowing the mechanical system to run at peak design efficiency.

Secondly, gas-phase air purification, while better known for filtration, can contribute to energy efficiency. The recently approved Indoor Air Quality Procedure (IAQP) from American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 62.1, Ventilation for Acceptable Indoor Air Quality, allows for reduced outdoor air requirements when an ‘air-cleaning’ system is used to remove gaseous airborne contaminants in the re-circulated indoor air. Reducing outdoor air, and the costs for conditioning it, promise significant energy savings, says Dean Tompkins, PhD, P.Eng., an air purification and IAQ consultant, and past chair of the ASHRAE Technical Committee 2.3, “Gaseous Air Contaminants and Gas Contaminant Removal Equipment.”

Further, photocatalytic oxidation links UVGI and gas-phase air purification and enhances their efficiency. It regenerates the gas-phase-activated carbon media, keeping its adsorption capacity and efficiency high, and energy consumption low.

UV-C increases HVAC coil efficiency

UVGI is an established technology for both surface and airborne disinfection in HVAC systems. The technology works by scrambling the DNA of micro-organisms—like mould, bacteria, viruses, and allergens—that prevents them from reproducing. The UVGI lights are typically positioned downstream, facing the coils in air-conditioning systems.

Although effectiveness depends on exposure time and micro-organism type, all viruses, bacteria, mould, and other microbes are destroyed by UVGI light. Microbial growth affects HVAC system efficiency by fouling interior surfaces. Biological contaminants adhere to HVAC coils, which offer ideal environments for microbial growth. If left unchecked, microbial growth can coat air conditioning coils with multiple layers. This hinders the heat-transfer process and increases static pressure, which causes longer HVAC system run-times to satisfy set-point temperatures.

Keeping coils clean might be considered a maintenance and IAQ expense, but it pays back in energy efficiency. Small amounts of coil surface dirt, debris, or biological growth can significantly decrease operating efficiency.

Florida Hospital, an Orlando-based healthcare system with more than 2800 beds in locations throughout the state, documented the maintenance-reducing effects of UVGI installed in air-handling units (AHUs). The facility’s chief mechanical engineer (CME) Firouz Keikavousi, suggests use of UVGI improved static pressure, air velocity, and temperature in a test HVAC system. (This can be found in the article “UVC: Florida Hospital Puts HVAC Maintenance Under A New Light,” published in an issue of Engineered Systems in February 2004 by Firouz Keikavousi).

In Florida Hospital’s test, Keikavousi revealed static pressure over the coil decreased from 1.8- to 0.7-wg. within weeks of installing UV-C lamps. Air velocity doubled from 70 to 158 m (230 to 520 f) per minute and exiting wet-bulb air temperature decreased from 14 to 11 C (57 to 53 F).

The improvement resulted in a capacity increase of 95,245 Btuh of air-conditioning. In dollar savings, the calculation was:

1(kW/ton) x 24 (hrs/day) x 365 (days/year) x $0.07 (electric rate)

The total savings per AHU—$4867—did not include the reduced maintenance costs. The total savings are approximately twice the cost of a UVGI system for the coil, which results in payback in less than one year. Considering the hospital’s many other facilities and HVAC systems, the estimated annual savings of using UVGI in all of them is significant. Similar systems are installed in hospitals throughout Canada.

Not every facility has the funding to periodically test IAQ, but most maintenance departments contend UV-C lights minimize mould growths on air-conditioning coils and AHU interior surfaces. As a result, biological growths and their distribution via the ventilation system is minimized.

For example, Geary Community Hospital in Junction City, Kan., has been using UVGI in new HVAC air-handlers supplying common areas, a patient tower, and operating rooms as part of a recent multi-million dollar expansion. While it is difficult to compare new technology to the hospital’s older HVAC units (installed before UVGI was available), the new AHUs with UVGI require no cleaning based on periodic visual inspections.

“We pressure-clean the original units’ coils annually, but the new units with UVGI have not required any maintenance cleaning in more than three years,” says Steve Rippert, the facility’s director of maintenance.