Thermal barriers and the protection of foamed plastic

By John A. Dalton

In Canada, products approved for use as a thermal barrier for foamed plastic must pass either CAN4-S124-M, Standard Method of Test for the Evaluation of Protective Coverings for Foamed Plastics, or CAN/ULC-S101, Standard Methods of Fire Endurance Tests of Building Construction and Materials, to comply with the National Building Code of Canada (NBC).

In the Canadian market, many products—typically fibre-based or cementitious materials—can meet these requirements. Unfortunately, there has been a growing trend amongst some suppliers of ‘paintable’ ignition barriers claiming their products meet the performance of a thermal barrier without actually passing either CAN4-S124-M or CAN/ULC-S101. This article provides the background on the qualities of acceptable solutions as a thermal barrier in accordance to the NBC, and discusses the current activities in the marketplace and the potential liability to the design/construction team and authority having jurisdiction (AHJ).

NBC test criteria for protecting foamed plastics

Sprayed polyurethane foam (SPF) insulation is combustible and may ignite when exposed to heat or fire. During the event of a fire, smoke and combustible gases can accumulate in interior, confined spaces and lead to a deadly flashover.1 These characteristics of foamed plastics are recognized within the NBC, which details the steps to be taken to protect building inhabitants from the effects of the materials’ burning.

The code specifically defines certain materials to be used as “thermal barriers” for foamed plastic insulation. These include gypsum board thicker than 12.7 mm (1/2 in.), concrete, and masonry. For other materials (that are not specifically identified), NBC stipulates testing/performance requirements to determine whether the material may be used as a thermal barrier. It splits this approval process into three categories based upon the flame spread rating of the foamed plastic insulation and details of the proposed building. Each category has its own testing requirements and pass/fail criteria.

As mentioned, the NBC includes testing thermal barriers according to CAN4-S124-M and/or CAN/ULC-S101—both standards use the same time-versus-temperature fire curve, but differ in the required sample size, orientation to the fire, number and location of thermocouples, and pass/fail criteria.

More importantly, with both standards, NBC requires the testing agency measure the temperatures at the interface of the foam plastic and thermal barrier. There have been recorded situations where tests have been run with the thermocouples on the backside of the assembly or with the thermocouples buried in the foam. Neither of these conditions would meet the requirements of NBC or the test standards mentioned above. The code is very clear in this respect.

In the first category, NBC, in 3.1.5.12 (titled “Combustible Insulation and its Protection”), allows for the use of a thermal barrier based on certain criteria. In a building required to be of noncombustible construction, foamed plastic insulation having a flame-spread rating not more than 25 is permitted, provided the insulation is protected from adjacent space in the building by a thermal barrier that meets the requirements of classification B when tested in conformance with CAN/ULC S124. As a general rule, if you can see foamed plastic insulation in the conditioned space of a building, it is a code violation.

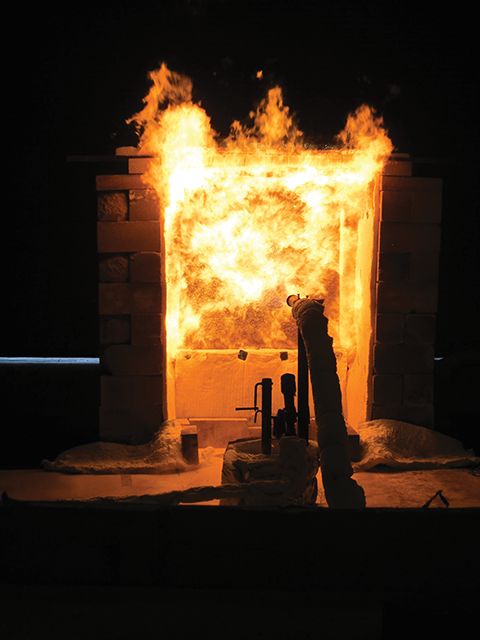

This is a small-scale test, with an exposed surface area of 0.49 m2 (5.3 sf), requiring temperature measurements at the interface of the thermal barrier and the foamed plastic. Purely a thermal transmission test, it measures the effectiveness of the thermal barrier to insulate the foamed plastic from heat and fire. The test must be run in a horizontal orientation. The material is exposed to a fire that reaches 700 C (1290 F) after 10 minutes (Figure 1).

Despite its small size, it is accepted as a severe test and one that provides an accurate measure of a thermal barrier’s effectiveness. Organizations such as ULC and Intertek indicate if a material has a Classification B rating based on CAN/ULC-S124. For a Classification B rating, the temperature rise at the interface of the tested thermal barrier material and the foamed plastic insulation cannot exceed an average of 140 C (252 F) for all the thermocouples or a maximum rise of 180 C (324 F) at any single thermocouple for 10 minutes (Figure 2).

In the second and third categories, for buildings sprinklered throughout or 18 m (59 ft) or shorter (from grade to the floor level of the top storey), NBC requires a thermal barrier tested to CAN/ULC S124 for foamed plastic insulation having flame spread ratings between 25 and 500 if the building is sprinklered throughout, or not more than 18 m (59 ft) from grade to the floor level of the top storey. Otherwise, as in for taller buildings or those without sprinklers, thermal barriers must be tested to CAN/ULC-S101. This is a full-scale test, larger than CAN/ULC S124, requiring an exposed surface of 9.3 m2 (100 sf) that can be run in both horizontal and vertical orientations to evaluate the intended orientation of the thermal barrier. As per Section 3.1.5.12 of the 2012 NBC, it establishes whether a material qualifies as a thermal barrier as follows:

2. Combustible insulation having a flame-spread rating of more than 25 but not more than 500 is permitted in the exterior walls of a building required to be of noncombustible construction, provided the insulation is protected by a thermal barrier that, when tested in conformance with CAN/ULC-S101 will not develop an average temperature rise of more than 140 C or a maximum temperature rise more than 180 C at any point on its unexposed face [(i.e. the unexposed face of the thermal barrier, which is the interface of the foam and the thermal barrier)] within 10 minutes.

3. Combustible insulation, having a flame-spread rating of more than 25 but not more than 500 on any exposed surface, or any surface that would be exposed by cutting through the material in any direction, is permitted in the interior walls, within ceilings and within roof assemblies of a building required to be of noncombustible construction, provided the insulation is protected from adjacent space in the building by a thermal barrier that, when tested in conformance with CAN/ULC-S101 will not develop an average temperature rise of more than 140 C or a maximum temperature rise of more than 180 C at any point on its unexposed face within 20 minutes, and will remain in place for not less than 40 minutes.

In addition to testing potential thermal barrier properties, CAN/ULC-S101 is primarily used to test the fire resistance of assemblies. However, for this type of testing, the thermocouples (and, therefore, temperature measurements) are located on the unexposed side of the assembly (Figure 3). This approach is different than what is used to assess a material’s effectiveness as a thermal barrier. The use of CAN/ULC-S101 in this fashion cannot be employed to approve thermal barriers because in this test procedure the thermocouples are not at the interface of the foam and thermal barrier as required by the National Building Code.

The specified slider id does not exist.