Improving indoor air through VOC sequestration

By Lucas J. Hamilton

Designing for high indoor air quality (IAQ) in both new construction and remodelling projects has become a primary objective of design professionals. This concern is due to the substantial impact indoor air has on the health and comfort of building occupants; recent studies compound the issue, revealing how much time the average person actually spends inside of homes and buildings.

For instance, Environment Canada has reported the average Canadian spends 90 per cent of his or her time indoors. (This statistic was first mentioned by Environment Minister John Baird in an April 2007 speech, but likely goes back further. Also, visit www.hc-sc.gc.ca/ewh-semt/air/in/poll/index-eng.php). This, coupled with the American Academy of Allergy, Asthma, and Immunology’s (AAAAI’s) assertion half of all respiratory illnesses are either caused or aggravated by indoor air pollutants, makes a solid case for the importance of cleaner interior air. (For more on AAAAI, visit www.aaai.org).

In addition to mould growth, one of the most formidable foes of IAQ and building occupant health is a group of chemicals known as volatile organic compounds (VOCs). This article explores these chemicals and their sources, and goes over industry guidelines for minimizing their levels in buildings; it also looks at new technologies building product manufacturers are employing to remove the compounds from interior air.

What are VOCs?

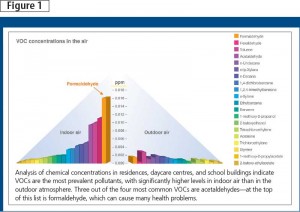

VOCs are organic chemical compounds that have high enough vapour pressures under normal conditions to significantly vapourize and enter the atmosphere after being emitted from certain solids or liquids. Samples taken of interior air in homes, daycare centres, and schools for chemical concentration analysis over the years have revealed VOCs are the leading pollutant of indoor air. In one study, concentrations in interior air registered up to 10 times higher than in outdoor air. (This information comes from the U.S. Environmental Protection Agency’s (EPA’s) “An Introduction to Indoor Air Quality (IAQ): Volatile Organic Compounds (VOC).” Visit www.epa.gov/iaq/voc.html). This issue creates a health concern, as many VOCs have the possibility of causing short- and long-term adverse health effects.

The ability of VOCs to cause health effects varies greatly, according to the U.S. Environmental Protection Agency (EPA). As with other chemicals, the effects of VOC exposure depends on several factors, including the type, amount, and time to which a person is exposed. Exposure to elevated levels of VOCs may cause irritation to the eyes, nose, and throat—headaches, nausea, and nerve problems may also occur. Some people will not appear to have any kind of reaction to fairly low amounts of VOCs, while others are fairly sensitive to them. Additionally, studies of animals have shown breathing some types of VOCs over a long period can increase the risk of getting cancer.

Many products commonly used in new construction and remodelling, or for ongoing building cleaning and maintenance, are sources of VOC emissions. These include:

- paints and wood stains;

- paint strippers;

- building materials;

- air fresheners;

- cleaning supplies;

- pesticides;

- adhesives;

- aerosol sprays;

- carpeting; and

- furnishings.

Each of these items employs organic chemicals for its manufacturing process, though many manufacturers are now focusing attention on minimizing the actual levels involved.

Products containing VOCs can release these chemicals while in use or in storage, and the emissions are often identified by strong odours. The labels of these products typically list VOC ingredients and recommend use in well-ventilated areas to help dilute the concentration. Building materials and furnishings that contain VOCs slowly release the chemicals over time. It is consequently a good idea to use building materials with low-VOC content and increase ventilation in areas with new carpeting or furnishings.

Examples of VOCs

The graph in Figure 1 lists the VOCs commonly found in interior air. Three of the top four highest VOC concentrations are from the aldehyde chemical family, with formaldehyde holding a commanding lead. Due to this, the reduction of formaldehyde in indoor air is one of the main goals in IAQ improvement.

Formaldehyde

Formaldehyde is a colourless gas that is most commonly characterized by its pungent odour when at a concentration greater than 0.2 parts per million (ppm). Formaldehyde is produced in large quantities around the world as a disinfectant and preservative, but is also used in textile finishing and in production of resins and adhesives. Formaldehyde-based resins are bonding agents for several building materials (e.g. particleboard, carpeting, and unsealed plywood), making them the main formaldehyde source in the majority of interior environments.

Irritant effects have been associated with formaldehyde concentrations that are in the median range of 0.5 parts per million, and concentrations as low as 0.01 ppm have been reported to affect sensitive individuals, who may experience nosebleeds, headaches, fatigue, or nausea. EPA recognizes the latter amount as an “informal level of concern.”

Indoor formaldehyde concentrations depend on the source’s age, ventilation rate, interior and exterior temperatures, and humidity. According to Health Canada, formaldehyde concentrations can also vary by as much as 50 per cent from day to day and season to season. (For more information, visit www.hc-sc.gc.ca/ewh-semt/pubs/air/office_building-immeubles_bureaux/formaldehyde-eng.php).

Sustainable building certification programs, such as the Canada Green Building Council’s (CaGBC’s) Leadership in Energy and Environmental Design (LEED) rating system, have developed standards for acceptable concentrations of formaldehyde in interior air. For example, LEED 2009 for New Construction (NC), Commercial Interiors (CI), and Schools, along with Green Guide for Healthcare, set the maximum concentration of formaldehyde at 27 parts per billion (ppb).

According to EPA, typical indoor concentrations of formaldehyde are 14 ppb for homes, 13 ppb for offices, and 18 ppb for schools. This stresses the need for increased emphasis on formaldehyde control. Health Canada recommends a one-hour exposure limit when formaldehyde concentrations are at 100 ppb and an eight-hour exposure limit when concentrations are at 40 ppb—the lower end of the exposure category.

Another industry standard to look for guidance on formaldehyde and other IAQ threats is American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 62.1, Energy Standard for Buildings Except Low-rise Residential Buildings. It sets the minimum ventilation rates for new construction, and provides information on how to improve IAQ in existing buildings. ASHRAE 62.1 also provides lists of the maximum contaminant levels for those spaces to maintain acceptable IAQ, which minimizes the potential for adverse health effects on occupants.

ASHRAE 62.1 also addresses ways to rid interior air of such pollutants. Methods include:

- remove particulate matter through filtration;

- monitor gas concentration;

- clean dehumidification systems, including drain pans; and

- clean humidifiers and water-spray systems.

In addition to the IAQ-improving guidelines provided by industry standards, product manufacturers are also working to help design professionals keep VOC levels down, especially in the wall assembly. In recent years, companies have developed several low-VOC insulation and gypsum board products to minimize emissions. One of the latest IAQ-improving developments involves the integration of VOC sequestration technology into building products.