An introduction to gypsum shaftwall systems

Fire-resistance-rated gypsum

A fire-rated gypsum shaftwall system consists of the four aforementioned components, assembled to achieve a desired fire resistance rating. Architects are responsible for specifying the system’s individual components, which contribute to an overall fire resistance rating typically falling between one and three hours. Gypsum panel components come from one manufacturer and are tested together as a functional unit.

Shaftwall systems are tested for fire resistance in accordance with Underwriters Laboratories of Canada (CAN/ULC) S101, Fire Endurance Tests of Building Construction and Materials, which is used for evaluating the fire ratings of building construction. Numerous ULC designs for shaftwall system configurations are available for inclusion in plans and specifications.

The following examples show some of the variations available when choosing components that meet a given fire rating specification.

One-hour rating, shaftwall finished on one side

The assembly, ULC W446, System F, offers one hour of fire resistance. The illustration in Figure 1 shows a 25-mm (1-in.) shaftliner panel and one layer of 16-mm (5/8-in.) Type X gypsum board on the corridor side.

Two-hour rating, shaftwall finished on one side

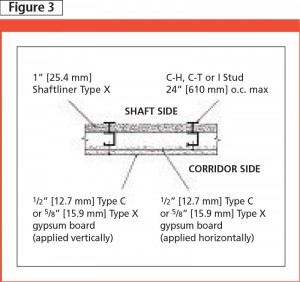

The assembly, ULC W446, System C, offers two hours of fire resistance. The illustration in Figure 2 shows two layers of 16-mm Type X gypsum board on the corridor side. The illustration in Figure 3 shows construction for a two-hour rating that also achieves a sound transmission class (STC) of 50 when constructed with fibreglass insulation and resilient channels.

Two-hour rating, shaftwall finished on both sides

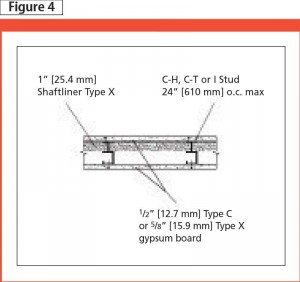

This assembly, ULC W446, System D, offers two hours of fire resistance. The illustration in Figure 4 shows two layers of 16-mm Type X gypsum board—one layer is installed on each side of the assembly. In areas where both sides of the shaftwall are visible, it is desirable to finish both sides.

Three-hour rating, shaftwall finished on one side

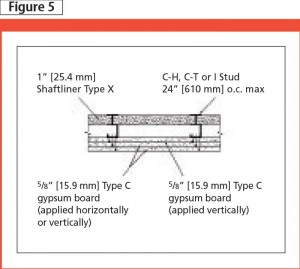

This assembly, ULC W446, System H, offers three hours of fire resistance. The illustration in Figure 5 displays three layers of 16-mm Type C gypsum board.

Three-hour rating, shaftwall finished on both sides

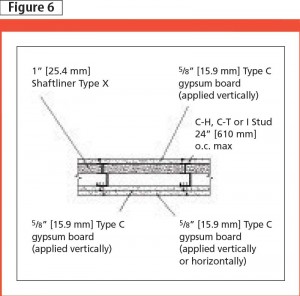

This assembly, ULC W446, System J, specifies three hours of fire resistance. Its illustration in Figure 6 shows three layers of 16-mm Type X gypsum board—two layers on the corridor side, one layer on the shaft side.

Horizontal shaftwall design

A horizontal shaftwall is designed in response to two different needs. The first is structural—when the top of a shaft or an exit corridor has the requirement for a fire rating of one to two hours, it is a natural candidate for a horizontal shaftwall. The second is when the plane of fire protection needs to be moved to the top of the plenum. This is the case when the plenum space is being used for utilities, such as HVAC or data cables.

From a construction perspective, a horizontal shaftwall is identical to the more common vertical one. The only differences are in the gypsum board thickness and the system weight. A horizontal shaftwall with a two-hour fire rating would be achieved using three layers of 12.7-mm (0.5-in.) Type-C gypsum board instead of two 16-mm (5/8-in.) layers on a vertical shaftwall.

There are span limitations that need to be considered when designing horizontal shaftwall systems. For example, spanning the horizontal distance at the tops of a stairwell or elevator shaft is usually not a problem. However, the width of an exit corridor can exceed the limit a horizontal shaftwall is capable of spanning, approximately 5.5 to 6.1 m (18 to 20 ft). In this case, special attention needs to be paid to the steel framing.

The shaftwall studs will need to be 0.835 mm (i.e. 20-gauge) and 152 mm (6 in.) deep to span 4.6 to 6.1 m (15 to 20 ft). The gauge and depth of the J-track will be the same.

The overall building project

There are three principal ways in which the specification of gypsum shaftwalls can affect a project.

Less overall complexity

Building a masonry shaftwall entails a more complex structure. Typical requirements include:

- specially skilled tradespeople, such as masons and other labourers trained in wall construction;

- formwork, which is needed for poured concrete walls and must be removed after the concrete has cured; and

- extensive scaffolding, which needs to be erected and removedon completion.

In comparison, a gypsum shaftwall can be assembled entirely by the drywall contractor. As the shaftwall is constructed from floor to floor, no additional structure (i.e. additional forms or scaffolding) is needed. Lightweight gypsum materials are easy to handle, which eliminates the need for equipment typically used to move heavy masonry materials from the point of delivery to the point

of use.

Safety

As the scaffolding required for a masonry shaft is not needed, no workers will be inside a shaft during construction. This eliminates the risks of associated construction injuries.

Cost

It is less costly to construct a gypsum shaftwall than a masonry one from a materials standpoint. For a typical 2.4 x 1.8 x 12.2-m (8 x 6 x 40-ft) two-hour elevator shaftwall enclosure with an area of 104 m2 (1120 sf) and a volume of 54.4 m3 (1920 cf), the gypsum would be about $5.50/sf, while the masonry is $7.65/sf, along with a scaffolding cost of $9.15/cf. Using labour/materials information from the 2007 RSMeans Building Construction Cost Data, this means the gypsum would be about $6160 and the masonry $8763.

With regard to other expenses, the amount of labour needed to build a gypsum shaftwall is less than that for a masonry shaftwall. Additionally, completion time is typically shorter with gypsum shaftwall systems because construction is typically conducted in parallel with other tasks. Further, certain types of glass-mat gypsum boards can be exposed to weather during construction, which expedites shaftwall construction (in comparison to traditional gypsum) because it can start before the building is weather-tight.

Specialty applications

Shaftwall assemblies incorporating gypsum board products formulated and tested for greater abuse resistance may be specified for some high-rise construction. An assembly that provides the protection needed to achieve a Level 2 rating for hard-body impact resistance consists of two layers of abuse-resistant Type X 16-mm (5/8-in.) gypsum board in a proprietary resistant assembly. (Ratings levels are from ‘1’ to ‘3,’ ascending with an ability to handle more hard-body impact. For more information, see ASTM C1629, Standard Classification for Abuse-resistant Non-decorated Interior Gypsum Panel Products and Fiber-reinforced Cement Panels). The abuse resistance must be on the corridor side, where any impact that could damage the shaftwall system would occur.

The basic conditions lending themselves to the construction of a gypsum shaftwall, not enclosing a shaft, are when an existing partition is only accessible from one side and the wall needs a rating of one to three hours. A good example of these conditions is when the wall is being built to achieve the required fire rating in a restaurant located in an airport terminal or mall, where adjoining businesses would restrict access to the wall.

Conclusion

Due to their performance, installation, cost, and safety benefits, gypsum shaftwall systems are becoming the standard for today’s high-rise buildings, as well as low-rise and mid-rise structures. Gypsum shaftwall systems make the installation process move more quickly than with traditional shaftwall materials, leading to a faster project completion. Once installed, they provide exceptional fire resistance, as well as long-lasting durability.

To design the best-performing shaftwall system, it is up to the designer to work with manufacturers and pay close attention to the fire-and abuse-resistance test results of individual products comprising the assembly and the details for penetrations. By doing this, the designer can ensure top performance, as well as minimize risk.

Pamela M. Shinkoda, P.Eng, CSC, is the systems innovation manager with CertainTeed Gypsum. She has been with the company for more than a decade and in the building products industry for over 20 years. Shinkoda is a member of the Ontario Building Envelope Council (OBEC), Construction Specifications Canada (CSC), the Canadian Fire Safety Association (CFSA), and the Gypsum Association (GA). She is also the vice-chair of ASTM International’s C 11 committee. Shinkoda can be contacted at pamela.shinkoda@saint-gobain.com.